Лабораторный реактор давления из нержавеющей стали с конденсацией и котелком для сбора

- Категория: >>>

- Поставщик: Weihai Huixin Chemical Machinery Co. Ltd.Weihai Ltd.

Сохранить в закладки 1601355105715:

Описание и отзывы

Характеристики

Product Description

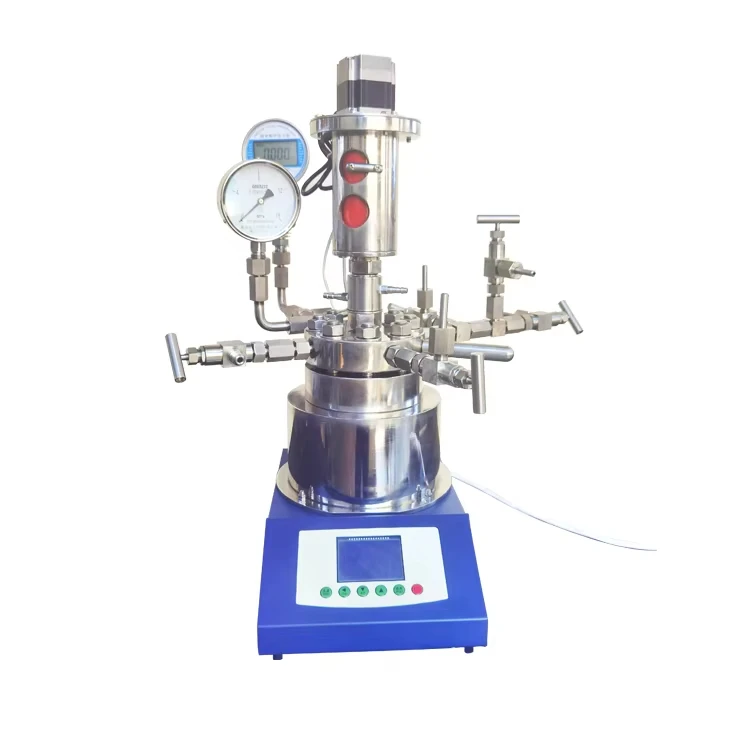

Stainless steel laboratory pressure reactor

laboratory pressure reactor with condensation and collect pot

laboratory pressure reactor with condensation

pressure reactor

laboratory pressure reactor with condensation and collect pot

laboratory pressure reactor with condensation

pressure reactor

Reaction vessels from HXCHEM made of stainless steel or Hastelloy C276 for small pressure vessels corrosion resistance, tightness and durability . For even higher media resistance requirements, Hastelloy or a titanium coating or a PTFE coating are available.

High pressure laboratory stirred pressure reactor

Equipped with condenser and receiver pot, valve and pipeline

Application:

Chemical development;Process optimization;Process development;Petrochemical research Corrosion test;Petrochemical development;Scale-up;Pilot-Plant;Mini-plant;Small-scale production.

HXCHEM designs and manufactures high-pressure reactors for research and development (R&D). The following reactor technologies are used:

* Laboratory batch reactors

* Semi-batch reactors (gas and/or liquid feed)

* Continuous flow reactors (continuous in one or more reagents)

* Internal-recycle reactors (conversion of kneaded studies in gas, liquid or slurry phase).

* Rotating basket reactors (for kinetic application and/or ageing studies).

* Laboratory batch reactors

* Semi-batch reactors (gas and/or liquid feed)

* Continuous flow reactors (continuous in one or more reagents)

* Internal-recycle reactors (conversion of kneaded studies in gas, liquid or slurry phase).

* Rotating basket reactors (for kinetic application and/or ageing studies).

GSH-1 STANDARD SPECIFICATION(100ml) | ||

Model No. | GSH-1 | |

Nominal Capacity (L) | 1L | |

Working Pressure (MPa) | 10 | |

Working Temperature (℃) | 300 | |

Stirring Speed (r/min) | 0-1300 | |

Motor power (kW) | 0.15 | |

Heating Power (kW) | 2 | |

Material | SS316 | |

Heating Method | General electric heating | |

Cooling Method | Internal spiral coils | |

Charging Method | Charging from above | |

Stirring type | Propeller type | |

Product Features

* SS-316, SS-316L, HastelloyB/C, Monel, Nickel, Inconel, Titanium, Zirconium

* 100ml to 5 liters volume.

* Up to 350 bar & 350°C.

* Electric heating with PID control

* Internal cooling coil

* Agitator & impeller

* Dip tube

* Temperature measuring tube

* Other

* Agitator & impeller

* Dip tube

* Temperature measuring tube

* Other

* Zero emission of hazardous fluids.

* Suitable for pressure fluctuations.

* Various capacities available.

* Compact Design.

* Suitable for pressure fluctuations.

* Various capacities available.

* Compact Design.

& Safety Device

* The pointer display is clear.

* Convenient installation, suitable for a variety of complex environments.

* Custom measuring range.

Intelligent digital temperature controlwith the temperature, stirring speed display & control and working time display

Product Paramenters

QUICK SELECTION(0.5liters to 5 liters) | ||||||||||

Model No. | GSH-0.5 | GSH-1 | GSH-2 | GSH-3 | GSH-5 | |||||

Nominal Capacity (L) | 0.5 | 1 | 2 | 3 | 5 | |||||

Working Pressure (MPa) | 10 | 10 | 10 | 10 | 10 | |||||

Working Temperature (℃) | 350 | 350 | 350 | 350 | 350 | |||||

Stirring Speed (r/min) | 0-1500 | 0-1500 | 0-1500 | 0-1500 | 0-1500 | |||||

Motor power (kW) | 0.15 | 0.2 | 0.2 | 0.2 | 0.6 | |||||

Heating Power (kW) | 1 | 2 | 2 | 3 | 4 | |||||

Material | SS304 or SS316 | |||||||||

Heating Method | General electric heating | |||||||||

Cooling Method | Internal spiral coils | |||||||||

Charging Method | Charging from above | |||||||||

Stirring type | Propeller, paddle type, anchor type or customized | |||||||||

Control panel | Temperature, time and heating voltage display Temperature adjustment control, accuracy±1 ℃ Stirring speed display and control | |||||||||

Standard fittings | Pressure Gage; Thermocouple; Internal Stirring System Liquid inlet and gas inlet with needle valve;Gas Release Valve Dip Tube; Safety Rupture Disc; Cooling Coil | |||||||||

Details Images

Recommend Products

Customization

Customized Specifications

If there has special process requires, HXHCEM will also customize for you!

Pls list your basis process parameters like follows:

1. Reactor volume

2. Operating Temperature

3. Operating Pressure

4. Reactor Material / contacting components material

5. Agitator type, and the Mixing Speed, motor power request?

6. With heating device or not? Heating type?

7. Internal cooling coil or not, exchange area?

8. Your other requests

......Contact us!

We like to help you to accomplish your plans.

If there has special process requires, HXHCEM will also customize for you!

Pls list your basis process parameters like follows:

1. Reactor volume

2. Operating Temperature

3. Operating Pressure

4. Reactor Material / contacting components material

5. Agitator type, and the Mixing Speed, motor power request?

6. With heating device or not? Heating type?

7. Internal cooling coil or not, exchange area?

8. Your other requests

......Contact us!

We like to help you to accomplish your plans.

Certifications

Pressure vessel certificate

ASME "U" Certificate

ISO9001 Certificate

ISO 14001 Certificate

ISO 45001 Certificate

CE Certificate

Company Introduction

Bench top pressure reactor

Floor stand pressure reactor

Lab reactor with lift & tilt

Pressure reactor

Lifting pressure reactor

Multi stage pressure reactor

Horizontal autoclaves

Lifting pilot reactor

Pilot scale pressure reactor

NOTES: The stirred autoclaves are usually equipped with a dished bottom. However, conical vessel bottoms or conical vessels are also available. The lid layout can be adapted as desired. When the container is open, the entire inner diameter is available for emptying, cleaning and inspection.

They are available up to a working pressure of 350 bar and a maximum temperature up to 500 °C. Available materials: stainless steel, Hastelloy, PTFE or nickel,Inconel coated.

Various heating/cooling systems, magnetic stirrers or magnetically coupled overhead stirrers, as well as a wide variety of gas and liquid supplies are available. Matching PTFE or glass liners (inlays), catalyst baskets complete the available options. They can be designed as single and parallel reactor plants. In addition to the standard configurations, you can also have plants specially tailored to your requirements.

The HiClave systems are suitable for numerous applications:

* (High pressure) extraction

* (High pressure) digestion

* (High pressure) hydrolysis

* (High pressure) hydrogenations

* Hydrothermal carbonization

* Development of hydrogen storage technology

* (radical, cationic, anionic and coordinative) polymerization

* numerous other high pressure syntheses

* (High pressure) digestion

* (High pressure) hydrolysis

* (High pressure) hydrogenations

* Hydrothermal carbonization

* Development of hydrogen storage technology

* (radical, cationic, anionic and coordinative) polymerization

* numerous other high pressure syntheses

We also manufacture pressure vessels and apparatus for laboratory and pilot plants according to your individual requirements and specifications. The special production of reaction vessels is a particular strength of our company which is based on decades of experience in apparatus and boiler construction. For example, we manufacture reactors for pressure and vacuum with special equipment and in special shapes from stainless steel and high-quality alloys according to your specifications.We manufacture complete experimental plants according to customer requirements. The add-on parts are interchangeable and changeable due to the modular system.

Похожие товары

5l мини-химические реакции системы стеклянный реактор

Высококачественный химический реактор 5л трехслойный стеклянный

Мини 5L высокого давления стекло химического реактора

Лабораторный механический перемешиваемый лабораторный Настольный реактор высокого давления

5 литров куртка стеклянный реактор электрическое отопление GR-5L

5-100l стеклянная лаборатория Staingless-Stell реактор

Высокооднородная ксеноновая лампа источник света 300 Вт для ксеноновой Nova холодного с фильтром

323 539,22 ₽

Новые поступления

Новинки товаров от производителей по оптовым ценам

Светлая Золотая морская солнечная энергия ландшафтное украшение постмодерн минималистский стиль чистая ручная роспись маслом 24x3 1 дюйм/60x80

35-53 $

Европейские антикварные простой Последние двойной металлической кровати

Автоматизированная складская система автоматического хранения в Гуанчжоу Eyda с эффективными стеллажами и

10 000-35 000 $

Декоративный чехол для PS5 Сменный Чехол консоли пластины Playstation5 пылезащитный с защитой от царапин

7,50-7,70 $

Лучшее качество детские подгузники для сухих подгузников новорожденных размер 2 4 и большие доставка или

3 $

Выключатель для формованного корпуса Schneider NSX100N 50KA AC 3P3D 25A TMD новая модель C10N3TM025

Буф2-.. М .. Краны

Оптовая продажа высококачественный сублимированный клубничный порошок Заводская поставка

5,50-6,40 $