Инструменты SCBN Твердые CBN вставки CNMN & CNGN120408/120410120416/120704/120708/120712 для тормозного барабана

- Категория: >>>

- Поставщик: Henan Wegcl New Materials Co. Ltd.Henan Ltd.

Сохранить в закладки 1601356036410:

Описание и отзывы

Характеристики

New Design Long Service Life Solid Cbn Insert Price Cheap CNMN

Product Introduction

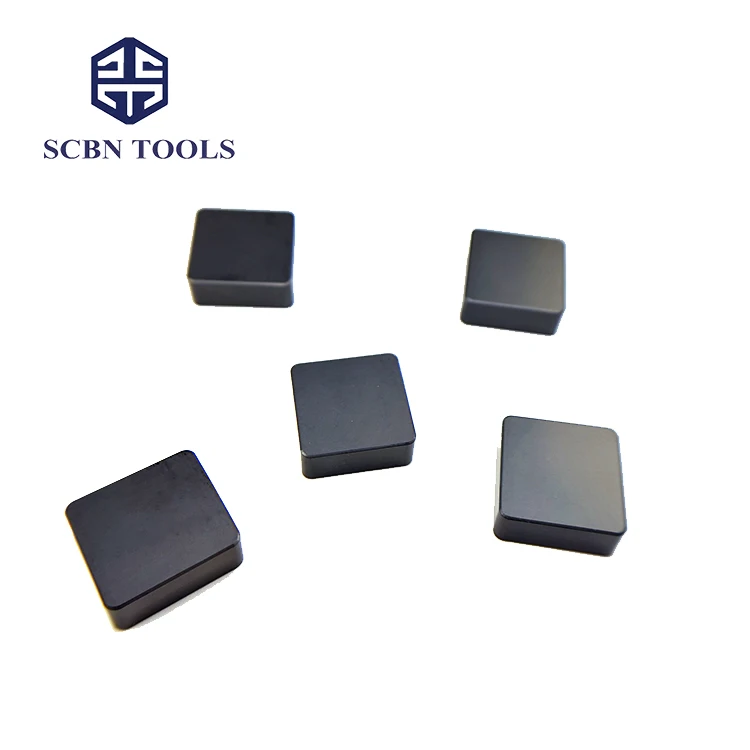

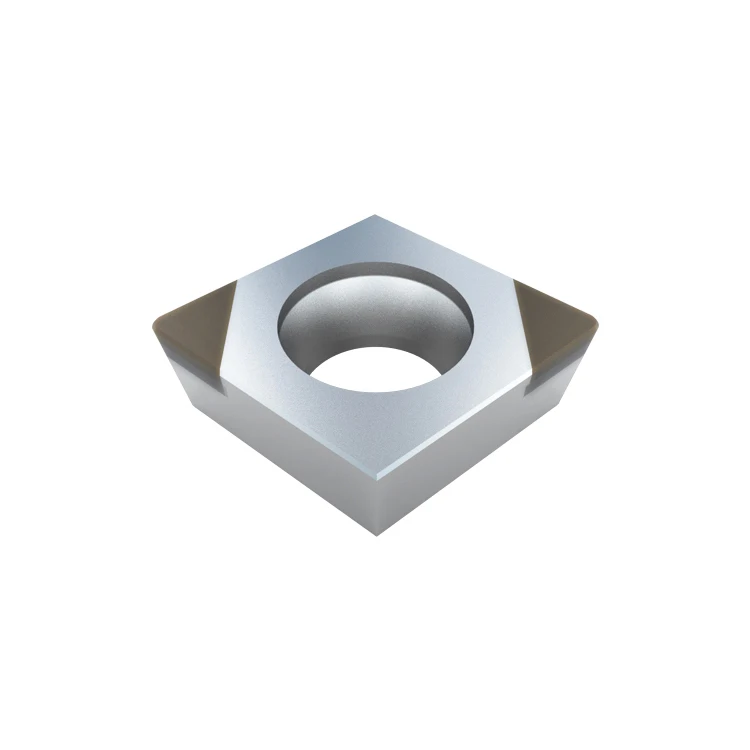

CNMN series CBN inserts have a shape of 80° rhombus, and the main cutting edge relief angle is 0°. They can be called CNMN/CNGN.

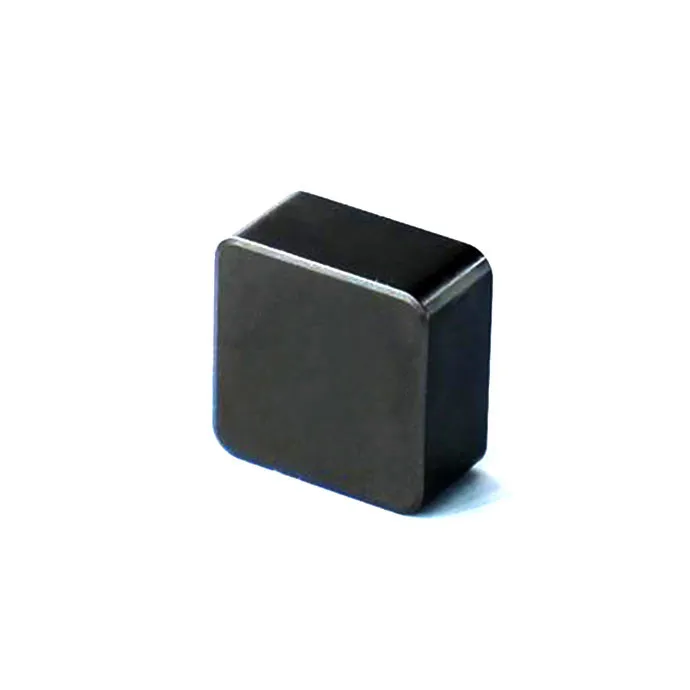

The inserts are non-porous and synthesized by polycrystalline cubic boron nitride at high temperature and ultra-high pressure, and are called CBN solid inserts. , has excellent heat resistance, wear resistance and chemical stability.

The inserts are non-porous and synthesized by polycrystalline cubic boron nitride at high temperature and ultra-high pressure, and are called CBN solid inserts. , has excellent heat resistance, wear resistance and chemical stability.

* CNMN solid CBN inserts can efficiently turn various cast iron and hardened steel parts, and realize turning instead of grinding. It is often used for turning gray cast iron brake discs, gray iron brake drums, boron cast iron cylinder liners, cast iron clutches, cast iron pressure plates, gray cast iron flanges, air conditioning compressors and other typical cast iron parts. Slurry pump and other parts.

* When using the solid CBN insert to process the slurry pump sheath, it is not affected by slag inclusion and blisters. And it is used for the processing of the impeller of the slurry pump, which is capable of strong intermittent cutting. After the surface of the workpiece is processed with a coated tool or a ceramic tool, the surface is hot to the touch, but after processing with an solid CBN tool, the hand feel is warm, because the chips can be well discharged during the processing to remove the cutting heat.

* CNMN120408 CBN inserts can also process HRC58-62 hardness 20CrMnTi gears, cutting depth ap=0.2mm, line speed Vc=150m/min, feed f=0.06mm/r. The use of solid CBN inserts CNMN processing can greatly improve the processing efficiency, and is a good choice for processing workpieces with general accuracy requirements.

* No matter how harsh or difficult the processing conditions are, SCBN TOOlS strives to provide users with the most available and economical processing solutions.

* When using the solid CBN insert to process the slurry pump sheath, it is not affected by slag inclusion and blisters. And it is used for the processing of the impeller of the slurry pump, which is capable of strong intermittent cutting. After the surface of the workpiece is processed with a coated tool or a ceramic tool, the surface is hot to the touch, but after processing with an solid CBN tool, the hand feel is warm, because the chips can be well discharged during the processing to remove the cutting heat.

* CNMN120408 CBN inserts can also process HRC58-62 hardness 20CrMnTi gears, cutting depth ap=0.2mm, line speed Vc=150m/min, feed f=0.06mm/r. The use of solid CBN inserts CNMN processing can greatly improve the processing efficiency, and is a good choice for processing workpieces with general accuracy requirements.

* No matter how harsh or difficult the processing conditions are, SCBN TOOlS strives to provide users with the most available and economical processing solutions.

Solid CBN Inserts CNMN/CNGN | ||||||||

Model | L(mm) | Φ(mm) | S(mm) | r(mm) | ||||

CNMN 090404 | 9 | 9.525 | 4.76 | 0.4 | ||||

CNMN 090408 | 9 | 9.525 | 4.76 | 0.8 | ||||

CNMN 090412 | 9 | 9.525 | 4.76 | 1.2 | ||||

CNMN 120404 | 12 | 12.7 | 4.76 | 0.4 | ||||

CNMN 120408 | 12 | 12.7 | 4.76 | 0.8 | ||||

CNMN 120412 | 12 | 12.7 | 4.76 | 1.2 | ||||

CNMN 120704 | 12 | 12.7 | 7.94 | 0.4 | ||||

CNMN 120708 | 12 | 12.7 | 7.94 | 0.8 | ||||

CNMN 120712 | 12 | 12.7 | 7.94 | 1.2 | ||||

All above models can be offered with wiper, different dimple

and coating service. Specific for Brake Disc Industry, can replace

various brands of ceramic blades with advantages.

Carbide Inserts + Ceramic Inserts

Processing procedures: Rough machining, Semi-finishing and finishing are completed on two machine tools respectively.

Disadvantages: Double clamping, low processing efficiency, difficult to guarantee processing accuracy, low cutting efficiency of carbide coated blades, poor surface finish of brake disc, large cutting resistance, stress on the surface of castings, and large dimensional fluctuations.

Disadvantages: Double clamping, low processing efficiency, difficult to guarantee processing accuracy, low cutting efficiency of carbide coated blades, poor surface finish of brake disc, large cutting resistance, stress on the surface of castings, and large dimensional fluctuations.

PCBN Brazed Inserts

Processing procedures: Rough machining and finishing machining are completed on two machine tools respectively.

Disadvantages: Double clamping, low processing efficiency, difficult to guarantee processing accuracy, PCBN welding blade, complex installation and adjustment of the tool tip, multiple adjustments to the tool, difficult to guarantee the processing accuracy of the brake surface.

Disadvantages: Double clamping, low processing efficiency, difficult to guarantee processing accuracy, PCBN welding blade, complex installation and adjustment of the tool tip, multiple adjustments to the tool, difficult to guarantee the processing accuracy of the brake surface.

Processing No. | Processing Part | CBN Inserts Models and Grade | Suitable Tool Holder | Cutting Speed Vc (m/min) | Feed Rate Fr(mm/r) | Depth of Cut ap(mm) |

1.1 | (Wheel face facing Roughing) | SBN850 CNGN120412 S02020 | F27R-CCSN-D50*150-CN1204 | 400-500 | 0.3~0.5 | 1.5~2 |

2.1 | (Internal roughing | SBN850 CNGN120412 S02020 | S40-260-CCLNL1204 | 400~750 | 0.3~0.5 | 1.5~2 |

3.1 | (Pad face roughing) | SBN850 CNGN120412 S02020 | CCLNL2525M1204 | 400-500 | 0.3~0.5 | 1.5~2 |

3.2 | (Wheel external roughing) | SBN850 CNGN120412 S02020 | CCLNL2525M1204 | 400~750 | 0.3~0.5 | 1.5~2 |

4.1 | (Groove roughing) | SBN850 RCMX060500 S02020 | CRDCN2525M0605 | 550~700 | 0.1~0.3 | 0.2~0.5 |

Processing No. | Processing Part | CBN Inserts Models and Grade | Suitable Tool Holder | Cutting Speed Vc (m/min) | Feed Rate Fr(mm/r) | Depth of Cut ap(mm) |

1.1 | (Wheel face facing Roughing) | SBN850 CNGN120412 S02020 | F27R-CCSN-D50*150-CN1204 | 400-500 | 0.3~0.5 | 1.5~2 |

2.1 | (Internal roughing | SBN850 CNGN120412 S02020 | S40-260-CCLNL1204 | 400~750 | 0.3~0.5 | 1.5~2 |

3.1 | (Pad face roughing) | SBN850 CNGN120412 S02020 | CCLNL2525M1204 | 400-500 | 0.3~0.5 | 1.5~2 |

3.2 | (Wheel external roughing) | SBN850 CNGN120412 S02020 | CCLNL2525M1204 | 400~750 | 0.3~0.5 | 1.5~2 |

4.1 | (Groove roughing) | SBN850 RCMX060500 S02020 | CRDCN2525M0605 | 550~700 | 0.1~0.3 | 0.2~0.5 |

Processing No. | Processing Part | CBN Inserts Models and Grade | Suitable Tool Holder | Cutting Speed Vc (m/min) | Feed Rate Fr(mm/r) | Depth of Cut ap(mm) |

1.1 | (wheel face finishing) | SBN850 CNGN120412 S02020 | F27L-D50*150-CCLN1207-1 | 650~750 | 0.2~0.3 | 0.2~0.5 |

2.1 | (wheel external finishig) | SBN850 CNGN120412 S02020 | F27L-D50*150-CCLN1207-1 | 650~750 | 0.2~0.3 | 0.2~0.5 |

2.2 | (external finishing) | SBN850 CNGN120412 S02020 | F27L-D50*150-CCLN1207-1 | 650~750 | 0.2~0.3 | 0.2~0.5 |

3.1 | (Groove finishing) | SBN850 RCMX060500 S02020 | CRDCN2525M0605 | 550-700 | 0.1~0.2 | 0.2~0.5 |

4.1 | (pad face semi-finishing) | SBN850 SCGN090408W | CSLCR2020K0904 | 650~750 | 0.2~0.3 | 0.2~0.5 |

Processing No. | Processing Part | CBN Inserts Models and Grade | Suitable Tool Holder | Cutting Speed Vc (m/min) | Feed Rate Fr(mm/r) | Depth of Cut ap(mm) |

1.1 | (pad face finishing) | SBN850 SCGN090408W | CSLCR2020K0904 | 650~750 | 0.2~0.3 | 0.2~0.5 |

2.1 | (starting point finishing)) | SBN850 CNGN120412 S02020 | F27L-D50*150-CCLN1204 | 650~750 | 0.2~0.3 | 0.2~0.5 |

3.1 | (internal finishing) | SBN850 CNGN120412 S02020 | F27L-D50*150-CCLN1204 | 650~750 | 0.2~0.3 | 0.2~0.5 |

1) The Solid CBN Insert is more suitable for high-speed, high-feed, and deep-cut processing.

2) The Solid CBN Insert is processed in one rough and fine process, with less processing steps, less tool change times, shortened processing time, and greatly improved processing efficiency.

2) The Solid CBN Insert is processed in one rough and fine process, with less processing steps, less tool change times, shortened processing time, and greatly improved processing efficiency.

Product Categories

Company Profile

Henan WEGCL New Materials Co., Ltd. (Named SCBN TOOLS), originated from China Henan New Materials Research Institute (formerly a comprehensive materials research institution directly under the Ministry of Machinery Industry of China), focusing on the research and development and production of superhard materials, is committed to providing the best cutting solutions and tools for global customers, and is regarded by customers as a reliable supplier of superhard material tools.

After several years of rapid development, SCBN TOOLS has formed an industrial pattern based on the advantages of raw materials and turning tools, and has realized the self-sufficiency of the whole industry chain. In the application technology and material research and development of superhard materials, it is at the leading level in China, and has passed the IOS9001 quality system certification.

The main products are: Solid CBN inserts, Tipped PCBN Inserts and other precision machine cutting tools, etc. Solid CBN Grade SBN800,SBN850, have unique advantages on cast iron materials. It has an absolute cost-effective advantage in the processing of typical parts brake discs and brake drums.

Products are widely used in gears, bearings, automobiles, iron and steel metallurgy and aerospace and other industries, has reached cooperation with many well-known enterprises around the world, and our products are exported to Germany, Italy, South Africa, South Korea and other countries in Southeast Asia.

After several years of rapid development, SCBN TOOLS has formed an industrial pattern based on the advantages of raw materials and turning tools, and has realized the self-sufficiency of the whole industry chain. In the application technology and material research and development of superhard materials, it is at the leading level in China, and has passed the IOS9001 quality system certification.

The main products are: Solid CBN inserts, Tipped PCBN Inserts and other precision machine cutting tools, etc. Solid CBN Grade SBN800,SBN850, have unique advantages on cast iron materials. It has an absolute cost-effective advantage in the processing of typical parts brake discs and brake drums.

Products are widely used in gears, bearings, automobiles, iron and steel metallurgy and aerospace and other industries, has reached cooperation with many well-known enterprises around the world, and our products are exported to Germany, Italy, South Africa, South Korea and other countries in Southeast Asia.

Company Advantage

Why Choose Us

01 Technical support: We have a professional technical team that provides comprehensive technical support and consultation services. Please contact us at any time when you have any problems and we will provide timely solutions.

02 Quality guarantee: All SCBN TOOLS products undergo strict quality control and testing to ensure they meet ISO standards. If there are any quality issues, please contact us and we will handle them promptly. We are committed to providing our customers with high-quality products and services.

03 Fast response service: We promise to respond within 24 hours of receiving your feedback, and provide you with a solution in the shortest possible time.

04 Fast shipping: We promise to arrange delivery as soon as possible after receiving your order and choose the fastest express delivery method to ensure you receive the product as soon as possible. (DHL, FedEx, UPS, TNT)

FAQ

1 Who Are We?

SCBN TOOLS are based in Zhengzhou,Henan,China,originated from China Henan New Materials Research Institute (formerly a comprehensive materials research institution directly under the Ministry of Machinery Industry of China).

2 How Can We Guarantee Quality?

Always a pre-production sample before mass production;

Always multiple quality inspection steps in the production and final inspection before shipment;

3 What Can You Buy From Us?

Solid cbn inserts,tipped pcbn inserts,coating pcbn inserts,wiper pcbn inserts,CBN Grooving Inserts,Chipbreaker PCBN Inserts and any other customized CBN Inserts.

4 Why Should You Buy From Us Not From Other Suppliers?

1) Integrating R&D, production and sales.

2) Formerly known as Henan Advanced Materials Research Institute, located in China's Superhard material Base.

3) Known for "SCBN TOOLS" Brand and have exported our products to various countries.

5 What Services Can We Provide?

Accepted Delivery Terms: FOB,CIF,EXW,Express Delivery;

Accepted Payment Currency:USD,EUR,CNY;

Accepted Payment Type: T/T,PayPal,Western Union,Cash;

Language Spoken:English,Chinese,German,Russian,Korean

SCBN TOOLS are based in Zhengzhou,Henan,China,originated from China Henan New Materials Research Institute (formerly a comprehensive materials research institution directly under the Ministry of Machinery Industry of China).

2 How Can We Guarantee Quality?

Always a pre-production sample before mass production;

Always multiple quality inspection steps in the production and final inspection before shipment;

3 What Can You Buy From Us?

Solid cbn inserts,tipped pcbn inserts,coating pcbn inserts,wiper pcbn inserts,CBN Grooving Inserts,Chipbreaker PCBN Inserts and any other customized CBN Inserts.

4 Why Should You Buy From Us Not From Other Suppliers?

1) Integrating R&D, production and sales.

2) Formerly known as Henan Advanced Materials Research Institute, located in China's Superhard material Base.

3) Known for "SCBN TOOLS" Brand and have exported our products to various countries.

5 What Services Can We Provide?

Accepted Delivery Terms: FOB,CIF,EXW,Express Delivery;

Accepted Payment Currency:USD,EUR,CNY;

Accepted Payment Type: T/T,PayPal,Western Union,Cash;

Language Spoken:English,Chinese,German,Russian,Korean

Похожие товары

Оптовая продажа инструменты для токарной обработки

1 131,26-2 828,14 ₽

Заводские изготовленные на заказ инструменты для резки тормозных дисков токарный станок режущие Cbn Pcbn поворотные вставки

Оптом pcbn blade CCGW09T3 CCGW1204 токарные инструменты для стальных CCGW cbn вставок

2 262,52-2 828,14 ₽

Оптовая продажа CCGW09T3 CCGW1204 pcbn токарные инструменты для стальных CCGW cbn вставок

2 262,52-2 828,14 ₽

CCGW120404/CCGW120408/CCGW120412 цена от производителя наконечники cbn инструменты для обработки закаленных стальных шестерен

1 018,14-1 357,51 ₽

Твердая Поворотная вставка CBN RCMX RCMV RCGX251200 S20020 для обработки HSS рулон чугунный валок S.G Черновая обработка

905,01-1 131,26 ₽

Замечательные вставки cbn SNMN090404/SNMN090412 для износостойких чугунных роликов режущие инструменты

Новые поступления

Новинки товаров от производителей по оптовым ценам

Changan 4*2 Электрический небольшой моющий грузовик высокого давления для продажи от производителя

3 890-4 890 $

45-тонный экологически чистый контейнерный штабелер SANY SRSC45C30 ISO сертифицированный кран

35 700-53 550 $

CL0126 304 U-образная металлическая плитка внутренняя отделка для плитки из нержавеющей стали Декоративная полоса

0,68-2,88 $

Черная Светоотражающая зимняя рабочая одежда для работы на открытом воздухе Улучшенная видимость и комфорт безопасности спецодежда

10,60-15 $

Костюм для выступлений

Оптическая полка для очков футляр

26,82-51,43 $

Оптовая Продажа 1000 Люмен USB Cob перезаряжаемые светодиодные фары красный свет безопасности для бега кемпинга водонепроницаемый Солнечный литий ионный

Производитель больничной униформы наборы и халаты удобные стильные для врачей персонала

8,49-9,99 $