Штамповка для штамповки

- Категория: >>>

- Поставщик: Hengshui Hongmaoda Mould Co. Ltd.Hengshui Ltd.

Сохранить в закладки 1601358631426:

Описание и отзывы

Характеристики

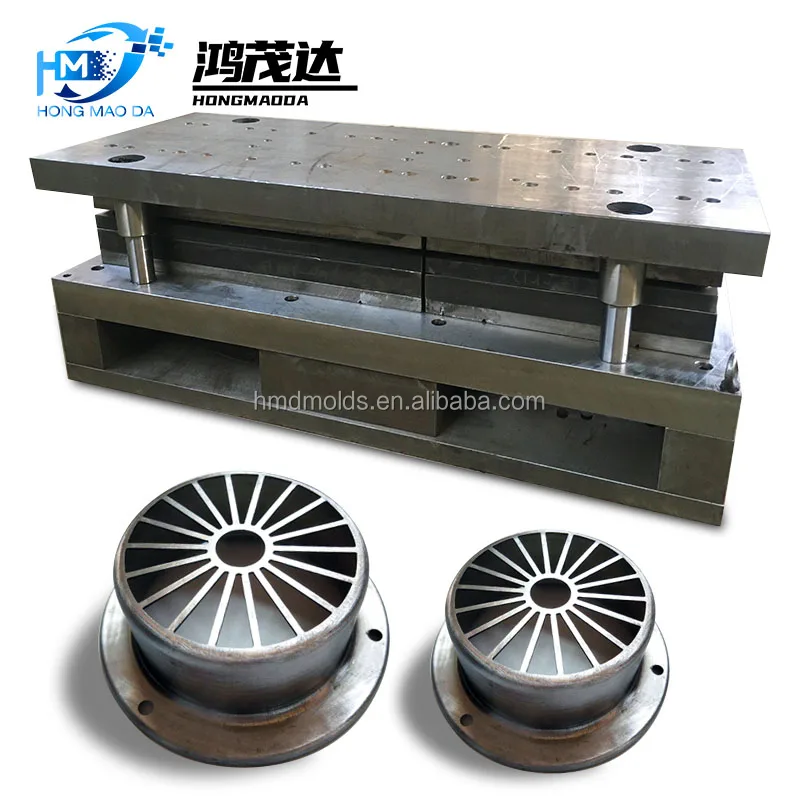

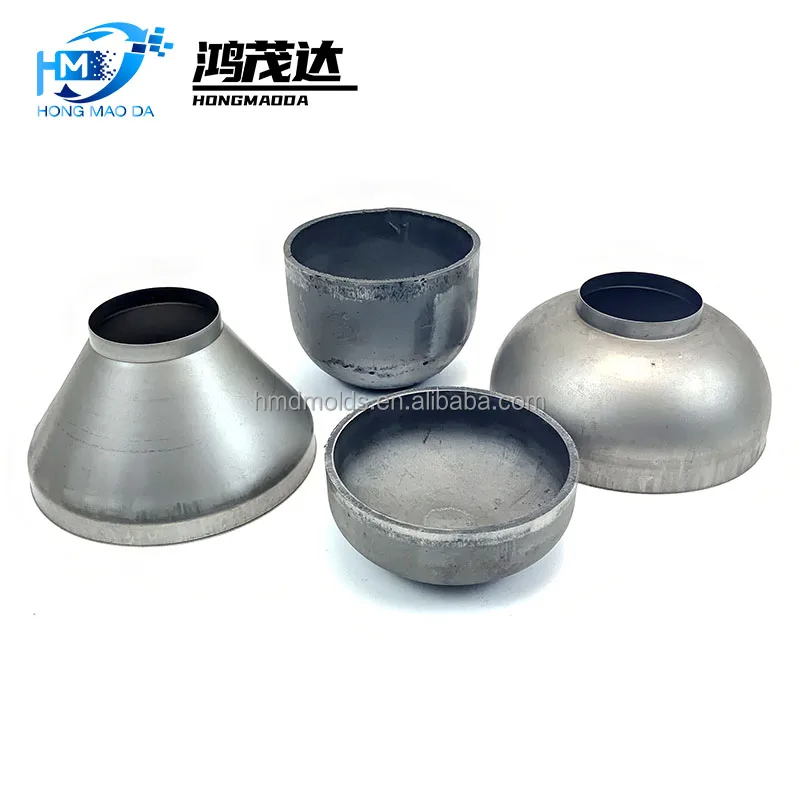

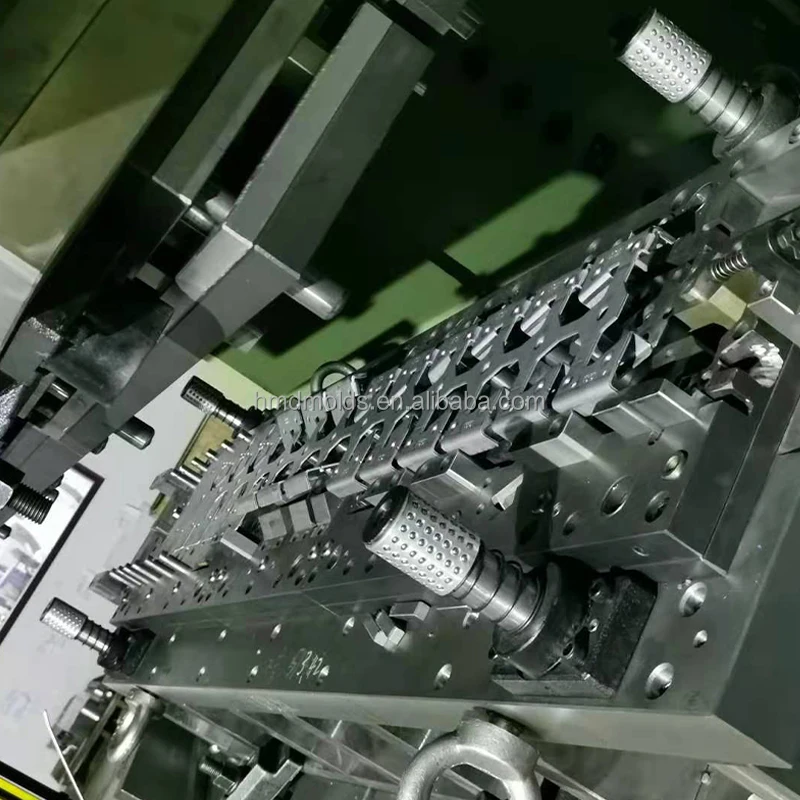

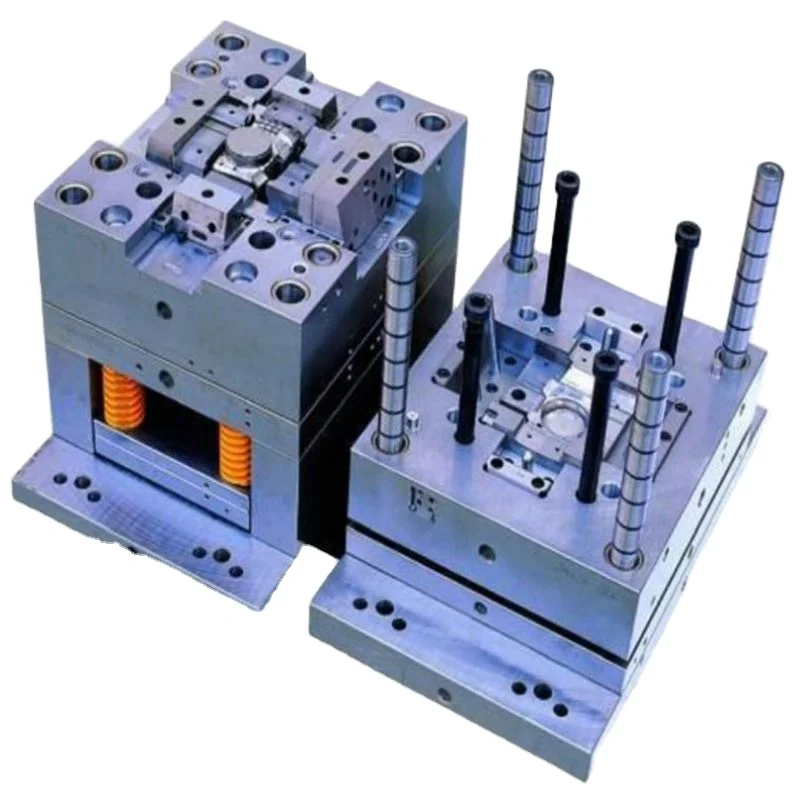

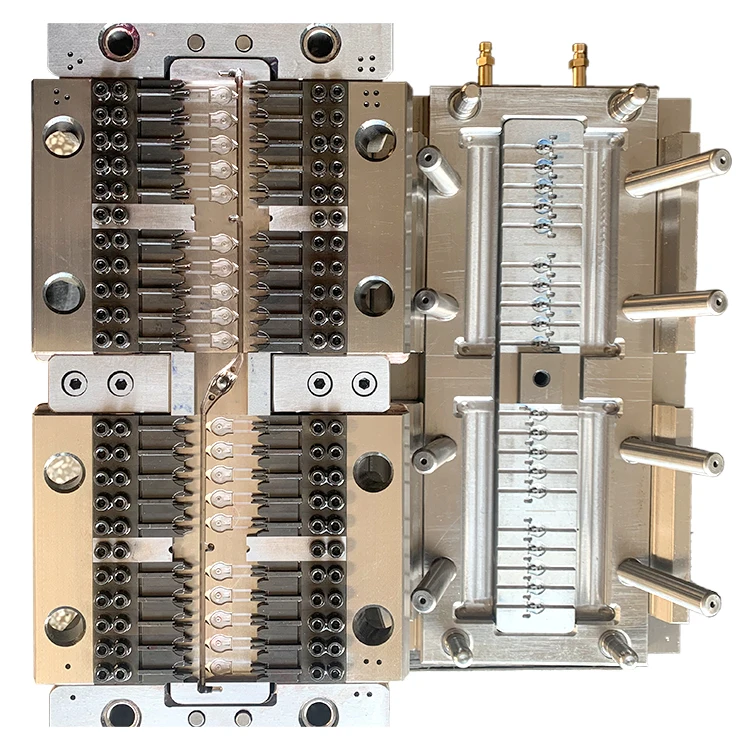

Product Name | professional manufacturer customed progressive stamping dies |

Material | Die plate:SKD11,Stripper plate:P20 or As specified by the customer |

Color | Natural color |

Standard | DIN GB ISO JIS BA ANSI |

Design file format | dwg, dxf, step, x_t, top, igs |

Tooling manufacturing cycle | 3 Weeks to 10 Weeks |

Forming way | Punching, Blanking, Bending, Burning, Deep drawing, Forming etc. |

Press machine tonnage | 30T to 315T |

Our Service

Guarantee period:

Our product quality guarantee period is 12 months from B/L date. During guarantee period, we will provide spare parts without any charge in case of quality discrepancy caused by us. If the malfunctions are caused by customers’ incorrect operations, we will provide customers spare parts at cost price. We also can offer flexible extended warranties according to the actual situation.

After-sales services:

Our engineer can go to your factory for installation and showing operation details on condition of you provide the round-trip air tickets, visa formalities, food and accommodation. In turn, your engineers can come to our factory for learning the installation, operation and maintenance for free.

Why Choose Us:

1. We will run the machine for a few days, and use your materials to do the test. Only guarantee the machine shows best performance, and then we will ship out.

2. Our elite teams can provide you professional, customized, and all-round services around the clock.

Guarantee period:

Our product quality guarantee period is 12 months from B/L date. During guarantee period, we will provide spare parts without any charge in case of quality discrepancy caused by us. If the malfunctions are caused by customers’ incorrect operations, we will provide customers spare parts at cost price. We also can offer flexible extended warranties according to the actual situation.

After-sales services:

Our engineer can go to your factory for installation and showing operation details on condition of you provide the round-trip air tickets, visa formalities, food and accommodation. In turn, your engineers can come to our factory for learning the installation, operation and maintenance for free.

Why Choose Us:

1. We will run the machine for a few days, and use your materials to do the test. Only guarantee the machine shows best performance, and then we will ship out.

2. Our elite teams can provide you professional, customized, and all-round services around the clock.

Hengshui Hongmaoda Mould Company Limited isa professional mold manufacturing enterprise onstamping die design,producing, sales and stamping service, to provide one stop service.

oWe have rich experience on production, andhave a professional design team and engineerteam. Our technology is supported by professorsfrom famous university.

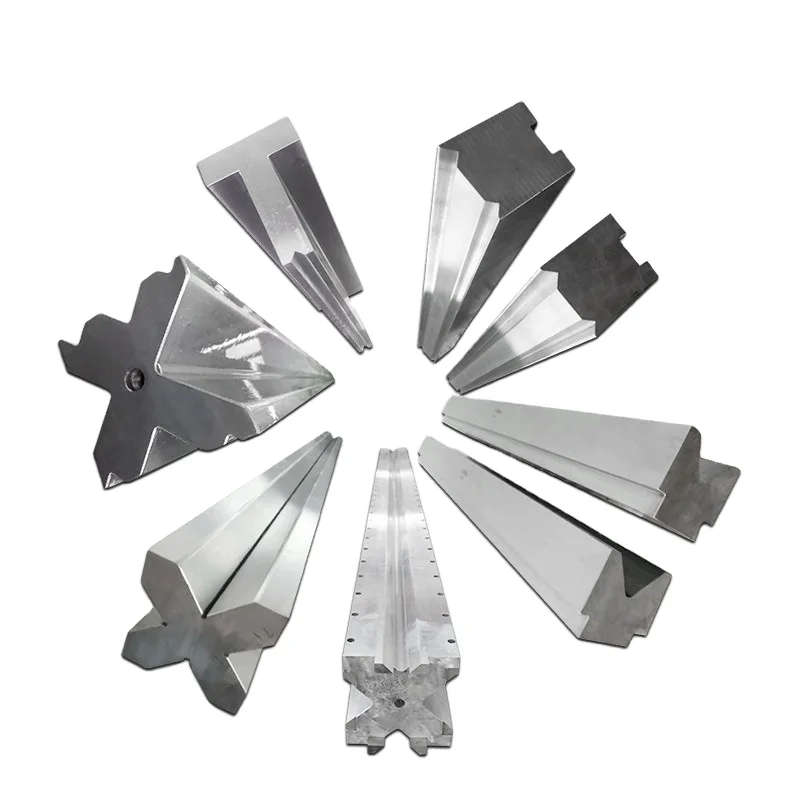

We can provide you with industry-leadingstamping die forming services, continue todevelop and invest the most advanced moldmanufacturing technology. We have uniqueinsights in sheet metal deep drawing,blanking,bending, forming and other complicated moldmanufacturing fields, can provide quality solutions.

oWe will undertake O D M,O E M and E DMorders, and strive to provide you with qualityproducts,through our strict quality control.

Sincerely hope to cooperate with you and createa better tomorrow together!

1. Besides molds, do you also produce products?

Yes, we can make your project for you in our factory. But we can only make it by making new molds... Then, on top of the new mold,use it to make parts. In other words, we don't have any existing molds. In short, we manufacture custom moulds and products, but we also provide reverse engineering services for our customers.

2. How can I get a quote?

First, we need our customers to provide their technical data, such as 2D, 3D drawings or samples. Upon receipt of your project, our team of experienced professionals will begin to study and evaluate it. In the meantime, our team will continue discussions with the designer to make sure every detail is clear. Finally, we give the customer a quote.

3. Does your company provide design services?

Absolutely. We have helped countless customers from Europe and North America to manufacture their new products. Our experiencedengineers provide our customers with useful advice to help them solve the problems they encounter when designing and machining molds and products.

Yes, we can make your project for you in our factory. But we can only make it by making new molds... Then, on top of the new mold,use it to make parts. In other words, we don't have any existing molds. In short, we manufacture custom moulds and products, but we also provide reverse engineering services for our customers.

2. How can I get a quote?

First, we need our customers to provide their technical data, such as 2D, 3D drawings or samples. Upon receipt of your project, our team of experienced professionals will begin to study and evaluate it. In the meantime, our team will continue discussions with the designer to make sure every detail is clear. Finally, we give the customer a quote.

3. Does your company provide design services?

Absolutely. We have helped countless customers from Europe and North America to manufacture their new products. Our experiencedengineers provide our customers with useful advice to help them solve the problems they encounter when designing and machining molds and products.

To know us more please contact us with your ideas / projects / drawings, so that we can start our studying / engineering job...

FAQ:

Q1: Avaliable for customized design drawings?A:Yes, DWG, DXF,DXW, IGES, STEP, PDF etc.Or you can send us samples for scanning.

Q2: Will my drawing be safe after you get it?

A:Yes, we can sign the NDA before you send the drawing.Or you can send us samples for scanning.

Q3: Can we know the production process without visiting the factory?

A:We will offer detailed production schedule and send weekly reports with digital pictures and videos which show the production

progress.

Q4:What craftsmanship do you have for processing accessories?

A:According to different products, different processes are used, such as machining, extrusion, injection molding, etc.

Q5: What areyour processing equipment?

A:CNC machining center, CNC lathe, milling machine, engraving machine, injection molding machine,extruder, molding machine.

Q6:Can injection products be surface treated? What are the surface treatments?

A:It's okay. Surface treatment: spray paint, silk screen,electroplating, etc.

Похожие товары

Формы для литья под давлением для изготовления молнии

177 424,30-309 050,52 ₽

Лидер продаж направляющая втулка для автомобиля диаметром 10-50 мм со средним плечом категория продуктов

2,88-3,88 $

JX радиатор с завода по индивидуальному заказу экструзия ЧПУ из сплава теплоотвод формы для теплоотвода

Высокоточная штамповка и форма прессового тормоза, гибочный станок, большая штамповочная машина

92 288,32-103 824,36 ₽

Низкая цена полимерные эпоксидные формы для изготовления ногтей

1,99 $

Поставщик пресс-форм для литья под давлением пластиковых изделий, производитель Китай

Заводская изготовленная на заказ прочная насадка для маникюра и набор удаления шарниров пистолет Sdl 4 штыря провода зачистки обжимной кабельный пробойник

0,65-0,85 $

Новые поступления

Новинки товаров от производителей по оптовым ценам

Светлая Золотая морская солнечная энергия ландшафтное украшение постмодерн минималистский стиль чистая ручная роспись маслом 24x3 1 дюйм/60x80

35-53 $

Европейские антикварные простой Последние двойной металлической кровати

Автоматизированная складская система автоматического хранения в Гуанчжоу Eyda с эффективными стеллажами и

10 000-35 000 $

Декоративный чехол для PS5 Сменный Чехол консоли пластины Playstation5 пылезащитный с защитой от царапин

7,50-7,70 $

Лучшее качество детские подгузники для сухих подгузников новорожденных размер 2 4 и большие доставка или

3 $

Выключатель для формованного корпуса Schneider NSX100N 50KA AC 3P3D 25A TMD новая модель C10N3TM025

Буф2-.. М .. Краны

Оптовая продажа высококачественный сублимированный клубничный порошок Заводская поставка

5,50-6,40 $