Бесшовные стальные трубы для труб из углеродистой стали высокого и среднего давления ASTM

- Категория: >>>

- Поставщик: Shandong Liaocheng Jiuyang Steel Pipe Manufacturing Co. Ltd.Shandong Ltd.

Сохранить в закладки 1601359761159:

Описание и отзывы

Характеристики

Product Description

Seamless pipe is a tubular section or hollow cylinder, usually but not necessarily of circular cross-section, used mainly to

convey substances which can flow — liquids and gases (fluids), slurries, powders and masses of small solids.

convey substances which can flow — liquids and gases (fluids), slurries, powders and masses of small solids.

How is seamless pipe formed?

Seamless pipes are formed using a process known as extrusion. Here is a general overview of how seamless pipes are formed:

1. Billet Preparation: The process starts with the preparation of a solid steel billet. The billet is a near-molten steel rod that

serves as the starting material for the seamless pipe.

serves as the starting material for the seamless pipe.

2. Heating: The billet is heated to a high temperature. This heating process helps to make the steel more malleable and easier to shape.

3. Piercing: The heated billet is then pierced with a mandrel. A mandrel is a cylindrical tool that is inserted into the billet. The mandrel helps to create a hollow cavity within the billet, which will eventually become the inside diameter of the seamless pipe.

4. Extrusion: Once the billet is pierced, it is subjected to extreme pressure and is pushed through a die. The die is a specially designed opening that shapes the billet into a seamless pipe. As the billet is pushed through the die, it undergoes plastic deformation and takes on the shape of the die, forming a seamless pipe.

5. Sizing and Finishing: After extrusion, the seamless pipe goes through a sizing process to achieve the desired dimensions and tolerances. It may also undergo additional finishing processes such as straightening, cutting, and heat treatment, depending on the specific requirements of the application.

Specification

Material | ASTMA106AASTMA106B,ASTMA106C,ASTMA179,ASTMA192 ASTMA210 | ||||||

ASTM A53A,ASTM A53B,ASTMA178C | |||||||

10#,20#,45#,Q235,Q345,Q195,Q215,Q345C,Q345A | |||||||

ST37,ST37-2,DIN 1629 ST35,DIN 1629 ST45,DIN 17175 ST35.8,DIN 17175DIN 17175 | |||||||

16Mn,Q345B,T1,T2,T5,T9,T11,T12,T22,T91,T92,P1,P2,P5,P9, | |||||||

P11,P12,P22,P91,P92,15CrMO,Cr5Mo,10CrMo910,12CrMo, | |||||||

13CrMo44,30CrMo,A333 GR.1,GR.3,GR.6,GR.7,etc | |||||||

Size | Outside Diameter:21.3-609.6mm | ||||||

Thickness :1.65mm-59.54mm | |||||||

Technique | Cold Rolled/Hot Rolled/cold drwan | ||||||

Standard | API 5CT, 5L; ASTM, BS, JIS, DIN | ||||||

Application | Widely used in Structure, Accessorize,Construction,Fluid transportation,machinery parts,the stress parts of the automobile tractor parts and so on | ||||||

Payment Terms | 30% TT deposit and 70% LC the balance | ||||||

Delivery time | 8-15days upon receipt of 30% deposit. | ||||||

What grade is seamless pipe?

Seamless pipes come in various grades, each designed for specific applications and environments. The choice of grade depends on factors like the intended use, temperature, pressure, and the type of conveyed fluid.

Some common grades of seamless pipes include:

1.Carbon Steel Grades: Carbon steel seamless pipes are widely used for general applications. Common grades include:

* ASTM A106: Standard specification for seamless carbon steel pipe for high-temperature service.

* ASTM A53: Standard specification for seamless and welded black and hot-dipped galvanized steel pipe.

* API 5L: Specification for line pipe used in oil and natural gas industries.

2.Alloy Steel Grades: Alloy steel seamless pipes offer enhanced strength, corrosion resistance, and high-temperatur performance.

* ASTM A335: Standard specification for seamless ferritic alloy-steel pipe for high-temperature service.

* ASTM A213: Standard specification for seamless ferritic and austenitic alloy-steel boiler, superheater, and heat-exchanger tubes.

3.Stainless Steel Grades: Stainless steel seamless pipes are known for their corrosion resistance. Common grades include:

* ASTM A312: Standard specification for seamless, welded, and heavily cold worked austenitic stainless steel pipes.

* ASTM A269: Standard specification for seamless and welded austenitic stainless steel tubing for general service.

4.Duplex and Super Duplex Grades: These are highly corrosion-resistant and offer superior strength. Examples include:

* ASTM A790: Standard specification for seamless and welded ferritic/austenitic stainless steel pipe.

5.Nickel Alloys: Seamless pipes made from nickel alloys are used in highly corrosive environments and high-temperature applications. Grades like Alloy 625, Alloy 825, and others are common.

6.Titanium Alloys: Seamless pipes made from titanium alloys offer exceptional corrosion resistance and are used in aerospace, chemical, and marine applications.

7.Copper Alloys: Seamless pipes made from copper alloys, such as C71500 and C70600, are used in marine and industrial applications due to their corrosion resistance and heat transfer properties.

8.High-Strength Low-Alloy (HSLA) Steel: These seamless pipes contain small alloying elements to enhance strength and toughness while maintaining good weldability. They find use in various structural and mechanical applications.

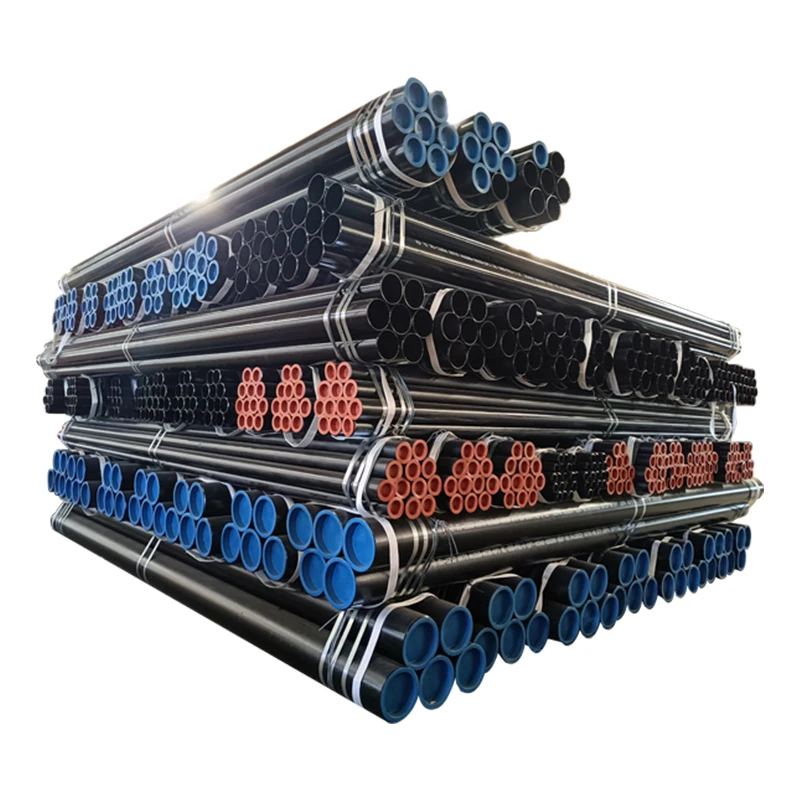

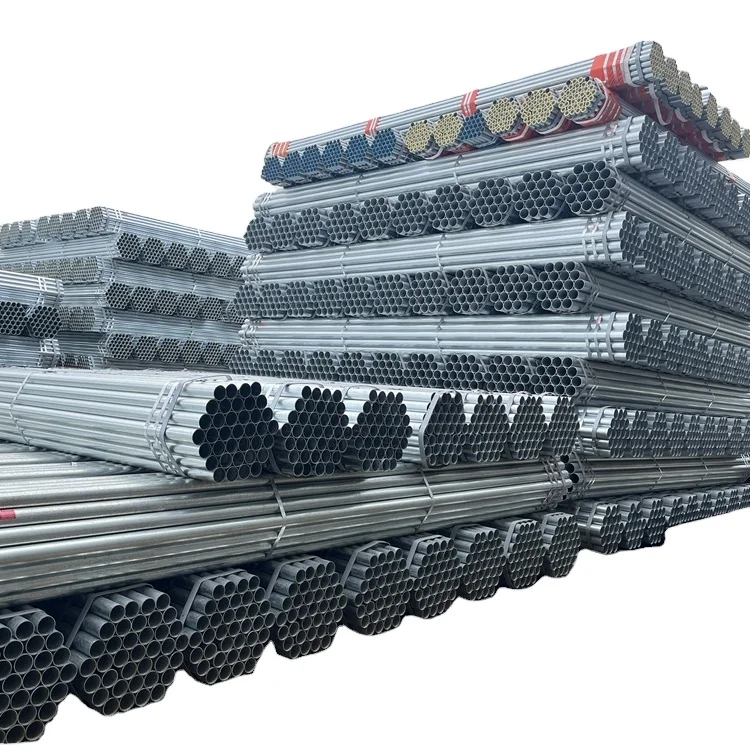

Product Show

Product Application

Company Profile

Shandong Liaocheng Jiuyang Steel Pipe Manufacturing Co., Ltd.

Shandong Liaocheng Jiuyang Steel Pipe Manufacturing Co., Ltd. was established in 2012 and is located in Liaocheng City, Shandong Province, with a registered capital of up to 50 million yuan. it is a professional steel enterprise that integrates domestic and international trade and industry.

The company's best-selling products include steel pipes, galvanized sheets/coils,color coated sheets/coils, steel structures, sandwich panels, corrugated panels, etc. These products are widely used in various fields such as chemical, pharmaceutical, power,railway automotive,paper making,construction,etc. The company has an annual sales revenue of 5 billion yuan and steel sales of several million tons.

Product standards are:GB, ASTM, API 5L, exported to Europe, the MiddLe East, Southeast Asia and other countries and regions, get a good reputation. My company all staff develops the enterprise with the wisdom, makes the brand by the good faith, "Science and technology as the source,d customer-oriented,cooperation first, win-win" as the company's business philosophy,Strict enterprise management. strengthen product quality,first-class equipment for customers to produce first-class products,first-class team for customers to do first-class service.

In order to provide customers with high-quality steel products, related services, and solutions,the company actively utilizes innovative technologies while always focusing on continuous improvement, strictly adhering to the highest business standards and professional ethics and committed to creating added value for customers in a positive employee environment. As a B2B wholesaler, the company takes pride in its excellent customer service and ability to provide reliablecost-effective steel solutions based on customer specifications.

The company's best-selling products include steel pipes, galvanized sheets/coils,color coated sheets/coils, steel structures, sandwich panels, corrugated panels, etc. These products are widely used in various fields such as chemical, pharmaceutical, power,railway automotive,paper making,construction,etc. The company has an annual sales revenue of 5 billion yuan and steel sales of several million tons.

Product standards are:GB, ASTM, API 5L, exported to Europe, the MiddLe East, Southeast Asia and other countries and regions, get a good reputation. My company all staff develops the enterprise with the wisdom, makes the brand by the good faith, "Science and technology as the source,d customer-oriented,cooperation first, win-win" as the company's business philosophy,Strict enterprise management. strengthen product quality,first-class equipment for customers to produce first-class products,first-class team for customers to do first-class service.

In order to provide customers with high-quality steel products, related services, and solutions,the company actively utilizes innovative technologies while always focusing on continuous improvement, strictly adhering to the highest business standards and professional ethics and committed to creating added value for customers in a positive employee environment. As a B2B wholesaler, the company takes pride in its excellent customer service and ability to provide reliablecost-effective steel solutions based on customer specifications.

Recommend Products

Packing & Delivery

1. In bundles with steel strips

2. In bundles+PVC blue package

3. In bulk

4. According to customers'

3. In bulk

4. According to customers'

requirements

FAQ

Q: How about the MOQ? If my first order qty is small, will you accept?

A: We would like to do our best to support your trial order qty, so even 1 pc or 1 kg is ok to start cooperation; because we have confidence to move on second order with your esteemed company.

Q: What is your payment terms ?

A: Commonly two payment term for new customers:

1) 30% T/T as deposit , 70% balance against B/L copy;

2) 100% Irrevocable L/C at sight;If you need any other terms, pls feel free to contact us too, we will try our best.

Q: How long is your delivery time?

A: Our daily inventory is more than 8000 tons, so for common product size, just need 5 days from stocks; if the special size from new production, delivery 7 days.

Q: How about the samples ? is it free or extra fees?

A: Yes, we would like to supply the samples before order; if the samples from stock, it will be free; if the samples from new production, we will charge some reasonable cost, but this amount will be deducted from your first order invoice.

Q: How to control and guarantee your shipment quality?

A: 1) All our factories are ISO9001, CEcertified facility;

A: We would like to do our best to support your trial order qty, so even 1 pc or 1 kg is ok to start cooperation; because we have confidence to move on second order with your esteemed company.

Q: What is your payment terms ?

A: Commonly two payment term for new customers:

1) 30% T/T as deposit , 70% balance against B/L copy;

2) 100% Irrevocable L/C at sight;If you need any other terms, pls feel free to contact us too, we will try our best.

Q: How long is your delivery time?

A: Our daily inventory is more than 8000 tons, so for common product size, just need 5 days from stocks; if the special size from new production, delivery 7 days.

Q: How about the samples ? is it free or extra fees?

A: Yes, we would like to supply the samples before order; if the samples from stock, it will be free; if the samples from new production, we will charge some reasonable cost, but this amount will be deducted from your first order invoice.

Q: How to control and guarantee your shipment quality?

A: 1) All our factories are ISO9001, CEcertified facility;

2) Ex factory inspection by our own laboratory.

Похожие товары

Труба из горячекатаной бесшовной углеродистой стали сертифицированная по стандарту ISO9001 12

65 067,41-72 297,12 ₽

Диаметр 1500 мм Две пластины в сборе гофре 68*13 гофрированная металлическая труба

156 643,76-162 668,52 ₽

Оцинкованная стальная труба 40 дюймов 2 дюйма предварительно оцинкованная сварная круглая железная для

75 911,98-78 321,88 ₽

ASTM A106/API 5L MS бесшовные стальные трубы от производителей углеродистая стальная труба горячекатаная круглая черная железная

60 247,60-69 887,22 ₽

casing tubing

Бесшовные стальные трубы производители индивидуальные полые для

C20 прецизионная отточенная стальная труба Q355D гидравлическая цилиндрическая

72 297,12-120 495,20 ₽

Новые поступления

Новинки товаров от производителей по оптовым ценам

Changan 4*2 Электрический небольшой моющий грузовик высокого давления для продажи от производителя

3 890-4 890 $

45-тонный экологически чистый контейнерный штабелер SANY SRSC45C30 ISO сертифицированный кран

35 700-53 550 $

CL0126 304 U-образная металлическая плитка внутренняя отделка для плитки из нержавеющей стали Декоративная полоса

0,68-2,88 $

Черная Светоотражающая зимняя рабочая одежда для работы на открытом воздухе Улучшенная видимость и комфорт безопасности спецодежда

10,60-15 $

Костюм для выступлений

Оптическая полка для очков футляр

26,82-51,43 $

Оптовая Продажа 1000 Люмен USB Cob перезаряжаемые светодиодные фары красный свет безопасности для бега кемпинга водонепроницаемый Солнечный литий ионный

Производитель больничной униформы наборы и халаты удобные стильные для врачей персонала

8,49-9,99 $