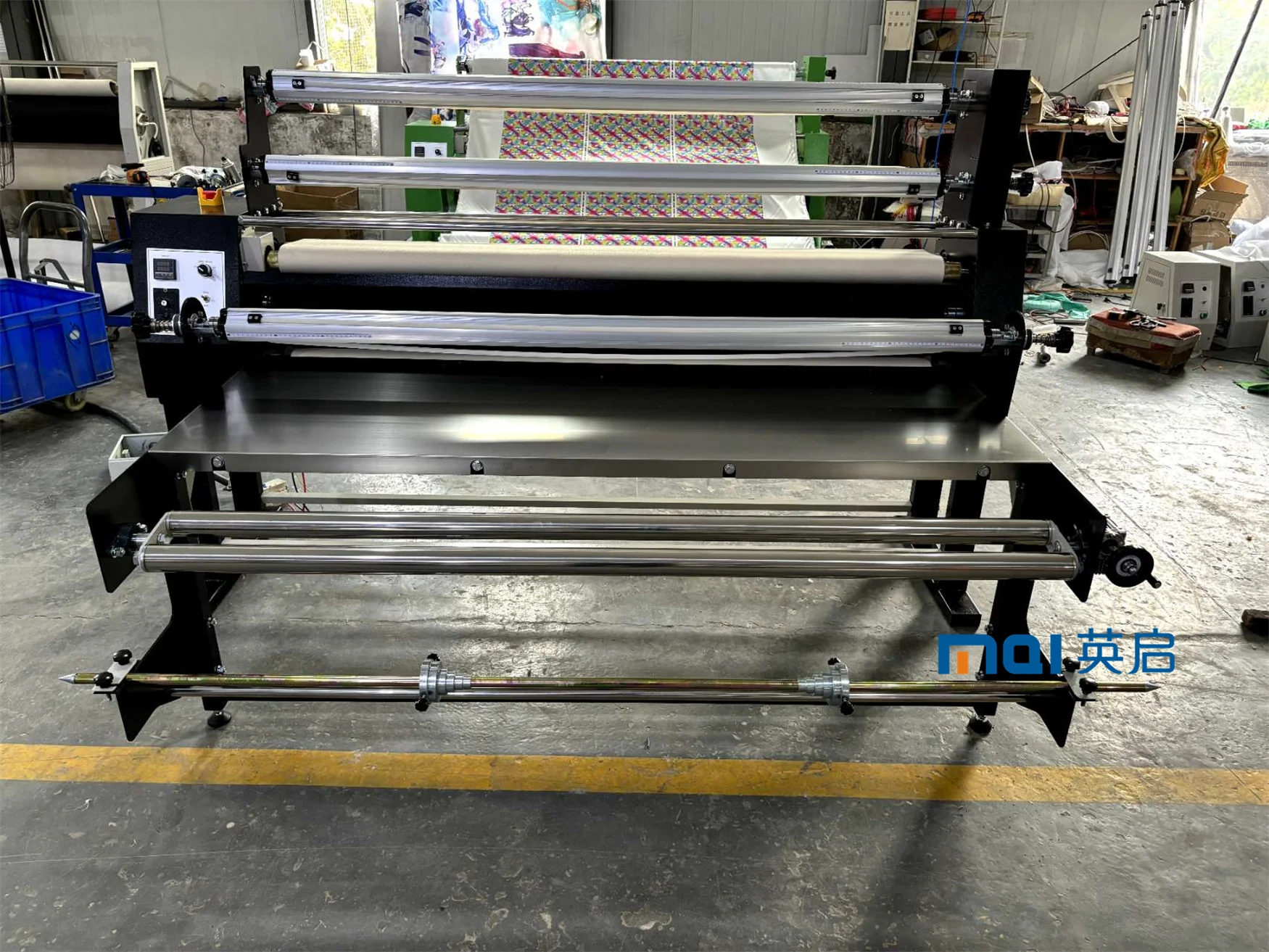

1622AT EL Профессиональный роторный термопресс

- Категория: >>>

- Поставщик: Guangzhou Inqi Electronic Instruments Co. Ltd.Guangzhou Ltd.

Сохранить в закладки 1601361009529:

Описание и отзывы

Характеристики

Specification

Electric Heating Drum Heat Transfer Machine | ||||

Parameter Name | YQ-1622ZT-EL | YQ-1822ZT-EL | ||

Machine Dimensions | 1420mm * 2140mm * 1420mm | 1420mm * 2340mm * 1420mm | ||

Heating Method | Heating by quartz heating tubes | Heating by quartz heating tubes | ||

Number of Electric Heating Tubes | 2 pieces | 2 pieces | ||

Roller Diameter | 220mm | 220mm | ||

Roller Surface | Teflon coating | Teflon coating | ||

Voltage | 220V | 220V | ||

Heating Power | 6.4KW | 7.2KW | ||

Total Power | 6.6KW | 7.4KW | ||

Speed | 20 - 100 meters per hour | 20 - 100 meters per hour | ||

Temperature Range | 30 - 250 degrees | 30 - 250 degrees | ||

Blanket Width | 1620mm | 1820mm | ||

Transfer Printing Width | 1500mm | 1700mm | ||

Tension System | 1 set | 1 set | ||

Unwinding System | 2 sets | 2 sets | ||

Rewinding System | 2 sets | 2 sets | ||

Platform Dimensions | 600mm * 1770mm * 650mm | 600mm * 1970mm * 650mm | ||

Blanket Adjustment Mode | Manual adjustment | Manual adjustment | ||

Wooden Box Packaging Dimensions | 2290mm * 750mm * 950mm | 2490mm * 750mm * 950mm | ||

Total Machine Weight | 285kg | 325kg | ||

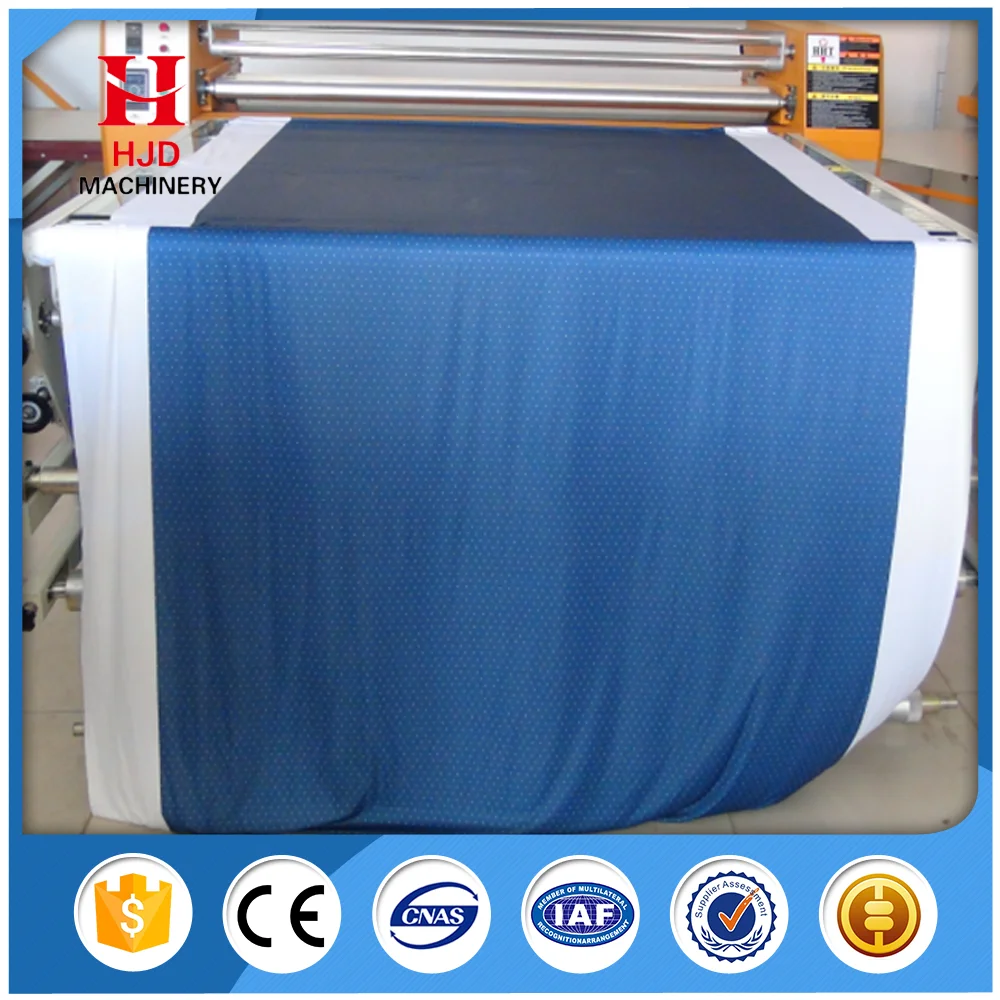

Roll heat transfer machine

Structural Components

* Heating Drum: It is the core component. Electric heating tubes or heating wires and other heating elements are installed inside

it. The surface of the drum is usually specially treated, such as being chrome-plated or coated with Teflon, to ensure good

thermal conductivity, wear resistance and non-stick properties.

* Drive System: Comprising motors, reducers, pulleys, synchronous belts or chains, etc., it is responsible for driving the drum

to rotate at a constant speed, ensuring the stability and uniformity of the transfer process.

* Pressurization System: Including pneumatic cylinders, hydraulic cylinders or springs and other pressurizing devices, which are

used to apply appropriate pressure to the substrate and the transfer paper during the transfer process to make them closely

adhere to each other and improve the transfer effect.

* Temperature Control System: Consisting of temperature sensors, temperature controllers, contactors, etc., it can monitor and

control the temperature of the heating drum in real time to ensure that the temperature fluctuates within the set range and

guarantee the transfer quality.

* Blanket or Conveyor Belt: Used for conveying the substrate, enabling the substrate to maintain good contact with the heating

drum during the transfer process and playing a role of buffering and protecting the substrate.

* Heating Drum: It is the core component. Electric heating tubes or heating wires and other heating elements are installed inside

it. The surface of the drum is usually specially treated, such as being chrome-plated or coated with Teflon, to ensure good

thermal conductivity, wear resistance and non-stick properties.

* Drive System: Comprising motors, reducers, pulleys, synchronous belts or chains, etc., it is responsible for driving the drum

to rotate at a constant speed, ensuring the stability and uniformity of the transfer process.

* Pressurization System: Including pneumatic cylinders, hydraulic cylinders or springs and other pressurizing devices, which are

used to apply appropriate pressure to the substrate and the transfer paper during the transfer process to make them closely

adhere to each other and improve the transfer effect.

* Temperature Control System: Consisting of temperature sensors, temperature controllers, contactors, etc., it can monitor and

control the temperature of the heating drum in real time to ensure that the temperature fluctuates within the set range and

guarantee the transfer quality.

* Blanket or Conveyor Belt: Used for conveying the substrate, enabling the substrate to maintain good contact with the heating

drum during the transfer process and playing a role of buffering and protecting the substrate.

Advantages

* High Transfer Efficiency: With the continuous rotation of the drum and in combination with automatic feeding and receiving

devices, continuous and rapid transfer operations can be achieved, greatly improving production efficiency. It is suitable for

large-scale production.

* Good Transfer Quality: The surface temperature of the heating drum is uniform. Under the pressure of the blanket or conveyor

belt, the transfer paper and the substrate are closely attached, which can ensure that the patterns are transferred clearly,

with vivid colors and high adhesion.

* Wide Range of Applications: It can perform transfer on various materials, such as fabrics, leather, paper, plastics, metals,

etc. It is especially suitable for continuous transfer on roll materials or large-format materials, such as cloth rolls,

wallpapers, advertising fabrics, etc.

* Easy to Operate: The equipment has a relatively high degree of automation, equipped with precise control functions for

parameters such as temperature, speed and pressure. The operation is relatively simple, and the technical requirements for

operators are relatively low.

* High Transfer Efficiency: With the continuous rotation of the drum and in combination with automatic feeding and receiving

devices, continuous and rapid transfer operations can be achieved, greatly improving production efficiency. It is suitable for

large-scale production.

* Good Transfer Quality: The surface temperature of the heating drum is uniform. Under the pressure of the blanket or conveyor

belt, the transfer paper and the substrate are closely attached, which can ensure that the patterns are transferred clearly,

with vivid colors and high adhesion.

* Wide Range of Applications: It can perform transfer on various materials, such as fabrics, leather, paper, plastics, metals,

etc. It is especially suitable for continuous transfer on roll materials or large-format materials, such as cloth rolls,

wallpapers, advertising fabrics, etc.

* Easy to Operate: The equipment has a relatively high degree of automation, equipped with precise control functions for

parameters such as temperature, speed and pressure. The operation is relatively simple, and the technical requirements for

operators are relatively low.

Application Fields

* Textile Printing and Dyeing Industry: Used for fabric printing, such as the pattern transfer of clothing fabrics and home

textile fabrics, which can quickly and efficiently produce fabrics with various patterns.

* Advertising and Decoration Industry: Patterns and logos for advertisements can be transferred onto advertising fabrics,

wallpapers, leather and other materials to produce outdoor advertisements, indoor decorative paintings, automotive interiors

and other products.

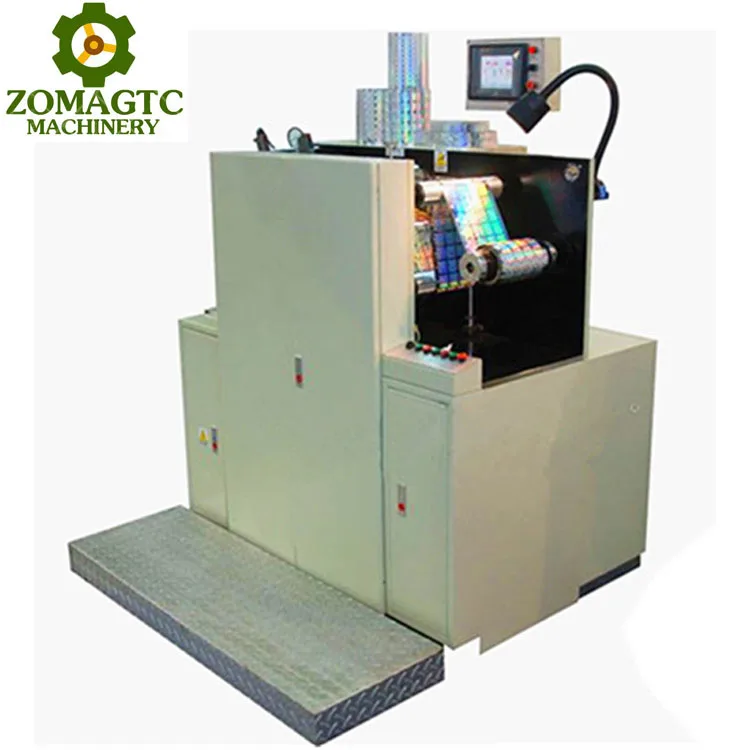

* Packaging and Printing Industry: Transfer can be carried on packaging materials such as paper and plastic films to achieve

personalized customization of product packaging and increase the added value of products.

* Gift Customization Industry: Photos, patterns, texts, etc. can be transferred onto cups, plates, mobile phone cases, keychains

and other gifts to make personalized gifts.

* Textile Printing and Dyeing Industry: Used for fabric printing, such as the pattern transfer of clothing fabrics and home

textile fabrics, which can quickly and efficiently produce fabrics with various patterns.

* Advertising and Decoration Industry: Patterns and logos for advertisements can be transferred onto advertising fabrics,

wallpapers, leather and other materials to produce outdoor advertisements, indoor decorative paintings, automotive interiors

and other products.

* Packaging and Printing Industry: Transfer can be carried on packaging materials such as paper and plastic films to achieve

personalized customization of product packaging and increase the added value of products.

* Gift Customization Industry: Photos, patterns, texts, etc. can be transferred onto cups, plates, mobile phone cases, keychains

and other gifts to make personalized gifts.

Precautions

* Safe Operation: During the operation of the equipment, the surface of the drum is at a high temperature. Operators should avoid

direct contact to prevent scalding. Meanwhile, the electrical system, heating elements and transmission parts of the equipment

should be inspected regularly to ensure the safe and reliable operation of the equipment.

* Maintenance: The surface of the heating drum, as well as blankets and conveyor belts, should be cleaned regularly to prevent

the accumulation of dust and debris, which may affect the transfer effect and the service life of the equipment. Regular

maintenance should be carried out on heating elements, transmission parts, etc., and worn parts should be replaced in a timely

manner.

* Temperature Control: According to different transfer materials and pattern requirements, reasonable settings should be made for

parameters such as the temperature of the heating drum, transfer speed and pressure to avoid transfer failure or damage to the

substrate caused by overly high or low temperatures.

* Safe Operation: During the operation of the equipment, the surface of the drum is at a high temperature. Operators should avoid

direct contact to prevent scalding. Meanwhile, the electrical system, heating elements and transmission parts of the equipment

should be inspected regularly to ensure the safe and reliable operation of the equipment.

* Maintenance: The surface of the heating drum, as well as blankets and conveyor belts, should be cleaned regularly to prevent

the accumulation of dust and debris, which may affect the transfer effect and the service life of the equipment. Regular

maintenance should be carried out on heating elements, transmission parts, etc., and worn parts should be replaced in a timely

manner.

* Temperature Control: According to different transfer materials and pattern requirements, reasonable settings should be made for

parameters such as the temperature of the heating drum, transfer speed and pressure to avoid transfer failure or damage to the

substrate caused by overly high or low temperatures.

Details Images

Packing & Delivery

YQ-1622ZT-EL 2290mm * 750mm * 950mm 285kg\t

YQ-1822ZT-EL 2490mm * 750mm * 950mm\t325kg

YQ-1822ZT-EL 2490mm * 750mm * 950mm\t325kg

Company Profile

INQI is located in Guangzhou, China, its high-tech enterprise integrating R&D, production, manufacturing, sales and maintenance services. Printing equipment, engraving equipment, laser equipment, marking equipment, hot stamping equipment and other products have entered the major markets of the world in related fields. Most of the products are sold in Europe, America, Southeast Asia, Africa, etc. The market is gradually establishing a good international marketing network channel.

Our company has gathered the core team of many years of sales and production experience in the industry. It can provide stable and high-quality products in response to the needs of customers and agents. At the same time, it provides customers with personalized matching solutions to enhance customer market competitiveness and truly realize the perfect combination of products and ideas. . Since its inception, the company has always adhered to the "customer first, quality first" company culture philosophy, and constantly lead the equipment industry to the development of high technology, has been recognized by the community, and has carried out extensive cooperation.

Join hands with INQI to win the future!

After-sales service

*24 hours Inquiry and consulting support

*Printer video and pictures available

*Video training how to instal the machine, training how to use the machine

* One year warranty(except head and consumable)

* Remote guidance

*Printer video and pictures available

*Video training how to instal the machine, training how to use the machine

* One year warranty(except head and consumable)

* Remote guidance

Feedback

Exhibition

Похожие товары

3D Мини Sub1 вакуумная машина для передачи тепла мобильный принтер крышки

215,00-257,00 $

250/OR-J голограмма пленка термопресс печатная машина

Полуавтоматический открытый широкоформатный сублимационный термопресс большой размер для продажи 60x80 см

379,00-415,00 $

1 6 м цифровая текстильная ткань краситель сублимационная бумага переводная печатная машина широкоформатный сублимационный принтер

Автоматическая верхняя скользящая пневматическая двойная станция термопресс

940,00-960,00 $

3d сублимационная вакуумная теплопередающая пресс-машина пленочная печатная машина для ПВХ

Мини 3D сублимационная вакуумная термопресс для DIY ПЭТ клейкая наклейка и чехол телефона печать Чехлы мобильных телефонов в наличии

218,00-238,00 $

Новые поступления

Новинки товаров от производителей по оптовым ценам

Hantek щупы осциллографа автоматический Тестовый Кабель Ht30a Bnc к банану двойная Банановая головка многоцелевое автомобильное

3,10-3,44 $

Горячая распродажа ручная работа традиционная деревянная урна для домашних животных квадратная коробка золы собак и кошек персонализированная Лучшая цена

Промышленная серия CL Бесшумная цепь стальная зубчатая Фланцевая контактная звездочка соединяющая бесшумные цепи

1-1,50 $

Irdmco экологически чистый минималистичный прямоугольный деревянный ящик для хранения стеллаж поделок и детских игрушек Домашняя мебель гостиной

Технология сенсорных перчаток и аксессуары для детей от дождя холода M725132-334

1,07-1,40 $

GY6 6 Pin AC гоночный CDI для CG125 CG250 двигателя Dirt Pit Bike ATV Quad

Парик из синтетического волокна для косплея

9,85-12,66 $

Прямая Продажа с фабрики 65 см Модернизированный подвесный стерео голографический проектор светодиодный вентилятор высокой четкости экран 3D дисплей

155-185 $