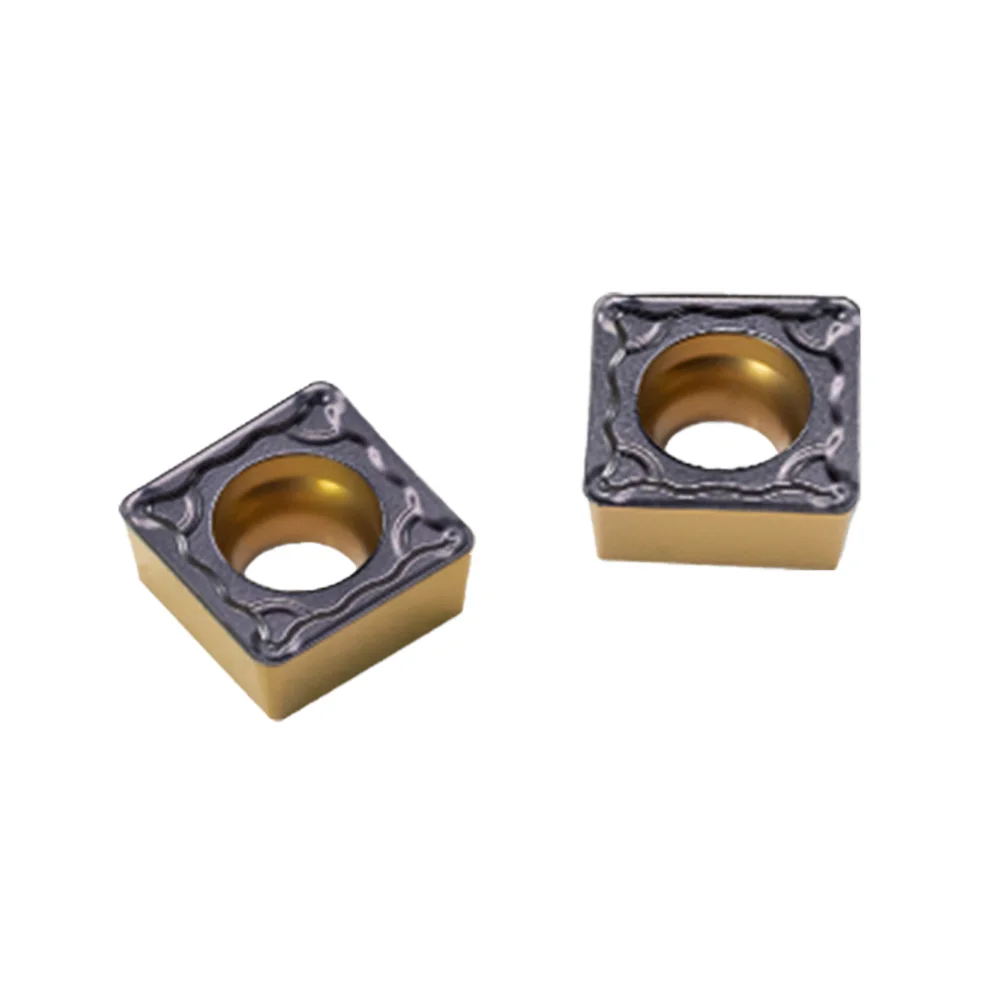

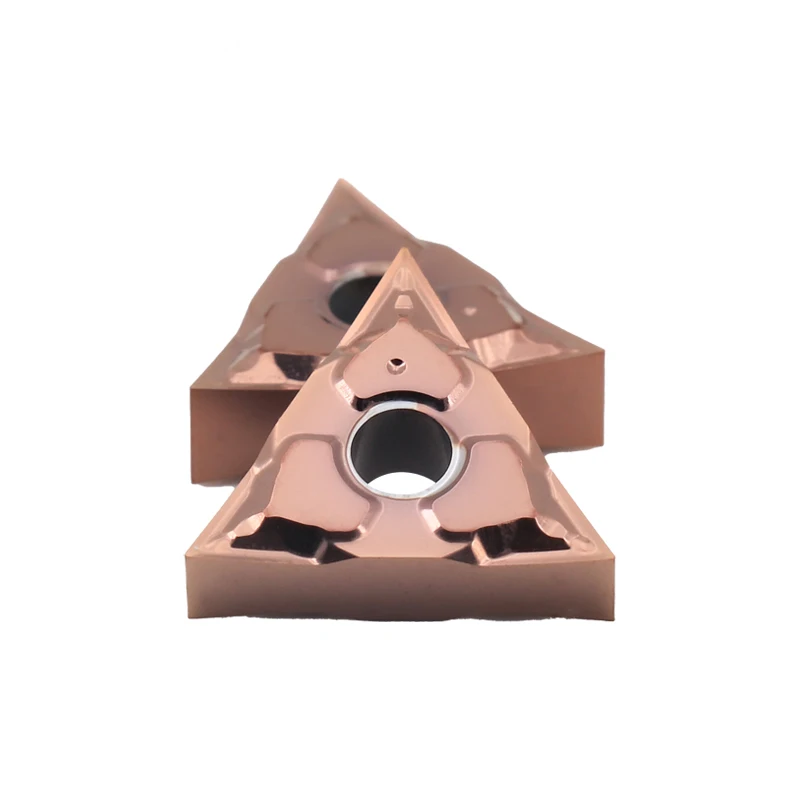

EATH TOOLS CCGT обработка твердых материалов Китай карбидные токарные вставки режущие инструменты CNC Индексируемые

- Категория: >>>

- Поставщик: Shenzhen Yi Teng Cutting Tool Co. Ltd.Shenzhen Ltd.

Сохранить в закладки 1601363140427:

Описание и отзывы

Характеристики

Products Description

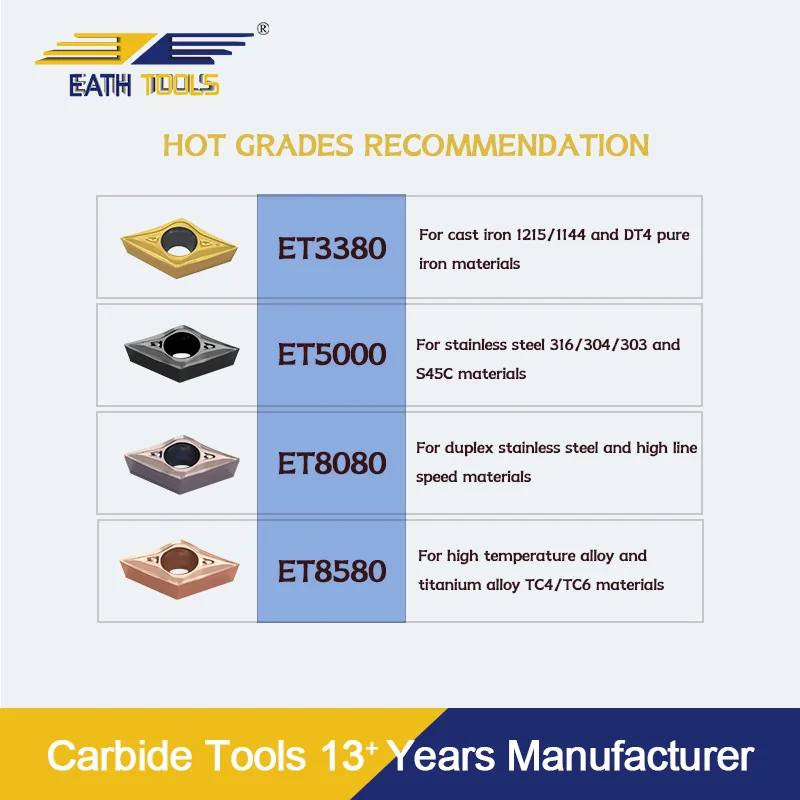

Grade for Inserts

Grade | Workpiece Material | Application |

ET3380 | Extremely wear-resistant material after Optimized, nano-thick film CVD coating. Continuous or lightly interrupted turning of Grey and Ductile cast iron, easy to wear to identify the yellow surface. | |

ET5080 | A matrix with both wear resistance and chipping resistance, and a tough coating with excellent adhesion. Intermittent steel - the first choice for general turning operations. | |

ET8080 | Submicron matrix, newly upgraded nanocomposite coating with high heat resistance and high toughness. The grade of choice for turning stainless steels and can also be used for complementary machining of milder steels | |

ET8580 | Ultra-fine grain matrix with optimized heat resistance and toughness, nano-multilayer coating with good wear resistance and oxidation resistance. The first choice for general processing of titanium alloy and kovar alloys. |

Our Advantages

Fast delivery

We are a professional manufacturer with automated equipment and advanced production lines. We can reasonably arrange production

time, master production rhythm, and deliver on time. OEM and ODM service are available.The production and delivery time of our standard products is generally 7-15 days.

time, master production rhythm, and deliver on time. OEM and ODM service are available.The production and delivery time of our standard products is generally 7-15 days.

Automated production lines and advanced equipment

We currently have more than 80 advanced equipment including Japan's Mazak five-axis linkage equipment and Germany's Walter five-axis grinder. It has established a carbide blade and steel product processing center with clear division of labor, a core research and design room, and a quality inspection center.

Strict quality control system

In terms of quality management, the company strictly implements the ISO9001:2015 quality management system; in terms of production

management, it fully implements lean production and JT system, and unswervingly implements 8s management; in terms of information

management, it fully introduces the ERP management system and information confidentiality system.

management, it fully implements lean production and JT system, and unswervingly implements 8s management; in terms of information

management, it fully introduces the ERP management system and information confidentiality system.

Company Profile

Shenzhen Yi Teng Cutting Tool Co., Ltd. was founded by Mr. Chen Yunhui in 2012. It is located in Shenzhen, Guangdong Province, a modern development metropolis. It is a high-precision tool factory integrating R&D, production and sales. Providing customers with solutions to reduce comprehensive processing costs and improving them is the strategic foundation of the company's development.

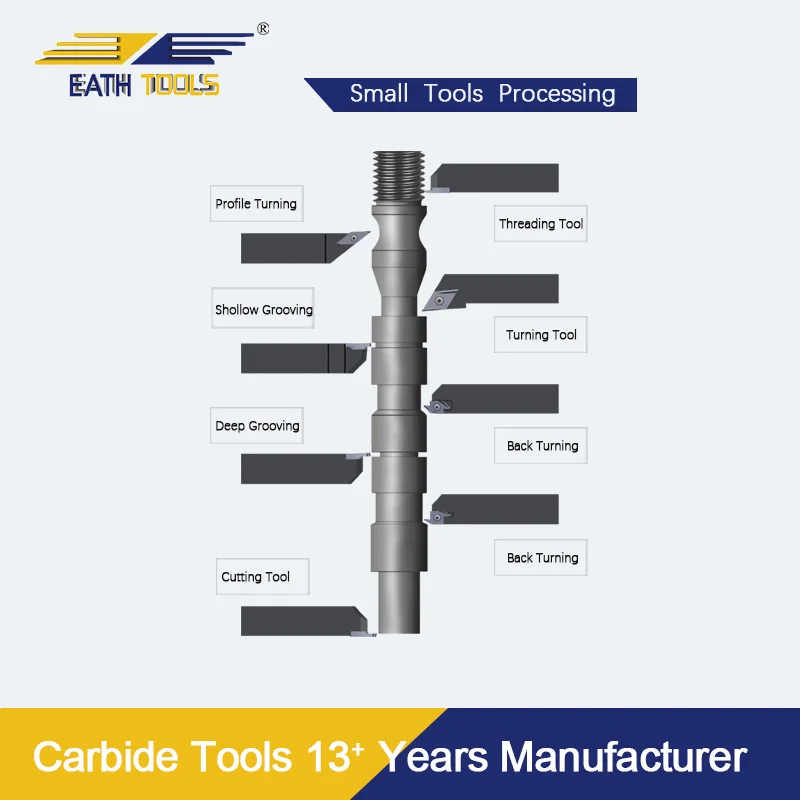

The company mainly produces carbide inserts such as turning tool series, milling cutter series, drilling series, slotting cutter series and threading series. It also produces turning discarded tool bars, high-speed steel tool bars, tungsten steel anti-vibration tool bars, tungsten steel threading tool bars, turning tool holders, milling cutters and other products.

At the same time, in order to meet customer needs and provide perfect solutions, we provide non-standard product customization services.After more than ten years of experience, technology and professional knowledge accumulation, Yiteng has gathered talents from all over the world and created a core team of professional core technical personnel, marketing and quality control personnel at home and abroad.

Yi Teng currently has five offices in major regions of China, namely Northeast Office, North China Office, Southwest Office, South China Office and Central China Office. At the same time, it connects with international business and its products are sold all over the world.

Yi Teng currently has five offices in major regions of China, namely Northeast Office, North China Office, Southwest Office, South China Office and Central China Office. At the same time, it connects with international business and its products are sold all over the world.

Certifications

Package & Shipment

By Sea

By Air

By Express

Payment

FAQ

1.What are your main products?

Shenzhen Yi Teng Cutting Tool Co., Ltd. mainly manufactures external turning tool holders,internal turning tool holders,milling cutter discs,grooving &threading tool holders ,tungsten carbide inserts and small tools.

2.How about the delivery time?

Usually we have stock for standard sizes, if no stock, our delivery time is within 7~15 days.

3.Are you a trading company or a factory?

We are a professional manufacturing factory over 13 years.

Contact Us

Address

Building 5, Baohu Industrial Park, Guangpei Community, Guanlan Street, Longhua District, Shenzhen City, Guangdong Province, China

Telephone

+86 181 1879 8239

Whatsapp

+86 181 1879 8239

+86 181 1879 8239

Email

chinayt92@eathtools.com

Website

www.eathtools.com

Похожие товары

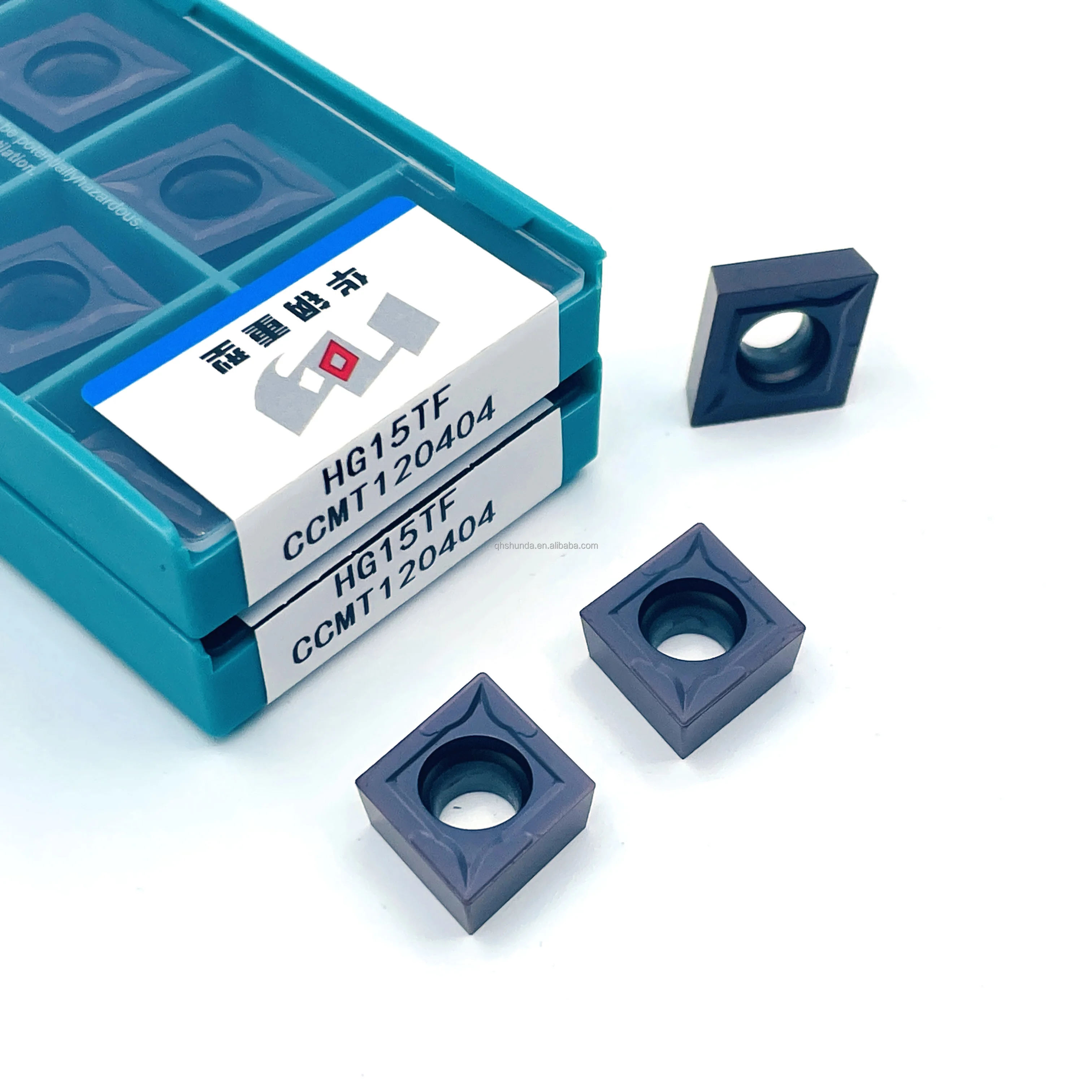

Карбидные вставки CCMT CCMT06/09/12 02 04 08 из нержавеющей стали с внутренним отверстием наружный круг расточные ромбовидные CNC токарные

0,69-1,65 $

Металлические WNMG080404-43 SHIYUE PS515 вставки для токарного твердосплавного инструмента

1,08-1,29 $

Твердосплавные Токарные вставки из нержавеющей стали

EATH инструменты TNGG16 высокоточная обработка Индексируемые высококачественные лезвия треугольные твердосплавные Токарные вставки

1,62-1,98 $

Карбидные вставки CCGX ccgx09t304 для алюминия

DNMG110404 DNMG110408 DNMG150404 DNMG150408 DNMG150412 DNMG150604 DNMG150608 YG3010 YG3020 YG3030 твердосплавные вставки

3,25 $

Металлический штангенциркуль

10,36 $

Новые поступления

Новинки товаров от производителей по оптовым ценам

Кокосовая стружка мягкая и сладкая на вкус без глютена запеченная Ароматизированная упаковка для приготовления пищи кондитерских

Медицинский одноразовый стерильный катетер

Эффективные акустические панели эффективные звукоизоляционные материалы для качественной

65% полиэстер/35% хлопок саржа TC камуфляжная ткань 220gsm с водонепроницаемым принтом

1,48-1,61 $

Органическое жидкое мыло для мытья рук оптом

0,66-1,46 $

Высокое качество Sunpal 450W-600W 48V фотоэлектрические солнечные панели 500W 500Wp 600W заводская цена с белой задней простыней

0,28-0,32 $

2025 руиба новый продукт зажим для пуповины оптовая продажа медицинский стерильный одноразовый пластиковый

Оптовая продажа индивидуальные синие 3-слойные одноразовые маски для лица хирургические медицинские защитные взрослых

40-41,80 $