CTB Постоянный Магнитный барабан железная руда марганцевая угольная шахта постоянный магнит Сильный магнитный для удаления влажного железа

- Категория: >>>

- Поставщик: Gongyi City Xiangrui Machinery Manufacturing Co. Ltd.Gongyi Ltd.

Сохранить в закладки 1601366435565:

Описание и отзывы

Характеристики

We are a real source factory, we will guarantee to have a video conference with you at any time, and on the premise of ensuring product quality, let you buy with confidence, use more assured.

We revolve around finding reputable overseas distributors, cultivating strong international relationships, and providing exceptional product after-sales support. Doing a good job in product after-sales service is our aim to achieve a mutually beneficial cooperation vision. We eagerly look forward to a fruitful and pleasant partnership with you.

We revolve around finding reputable overseas distributors, cultivating strong international relationships, and providing exceptional product after-sales support. Doing a good job in product after-sales service is our aim to achieve a mutually beneficial cooperation vision. We eagerly look forward to a fruitful and pleasant partnership with you.

Products Description

What is a magnetic separator?

A magnetic separator is a device that uses magnetic force to separate different substances. It is widely used in mining, steel, coal, building materials, chemical industry, environmental protection and other industries. Its working principle is based on the action of magnetic forces. It separates magnetic substances from the mixture by means of a magnetic field for the purpose of purifying or removing impurities.

Classification by magnetic field strength:

Weak magnetic field magnetic separator:mainly used for magnetic separation of strong magnetic objects, such as magnetite, pyrrhotite, etc.

Medium magnetic field magnetic separator:often used to separate medium magnetic minerals, such as ilmenite, pseudohematite, etc.

Medium magnetic field magnetic separator:often used to separate medium magnetic minerals, such as ilmenite, pseudohematite, etc.

Strong magnetic field magnetic separator: suitable for separating weak magnetic minerals, such as manganese ore, ilmenite, etc.

High gradient magnetic separator::Through the interaction between the magnetic medium and the particles, the magnetic field force and processing capacity of the magnetic separator are improved, which is mainly used to solve the separation problem of fine-grained minerals.

Classification by form of work:

Dry magnetic separator: suitable for water-deficient areas or places where wet operation is inconvenient, mainly used for the beneficiation of dry materials such as iron ore and manganese ore.

Wet magnetic separator: widely used in wet operating conditions, suitable for the separation of fine-grained ores.

How it works

1. Diffluent Trough 2. Dilution Water Pipe

3. Stainless Steel Cylinder 4. Adjusting Arm

5. Positioning Bolt 6. Frame

7. Tailings Dishcharg Mouth 8. Concentrate receiving hopper

9. Concentrates Discharging mouth 10. Ore Discharging Pipe

11. Driver 12. Rubber Gasket

13. Magnet Support 14. Magnet

The working principle of the magnetic separator:

When the slurry flows into the magnetic field, the highly magnetic minerals are absorbed on the surface of the bowl. The weak magnetic and non-magnetic minerals are discarded, and the strong magnetic minerals on the surface of the bowl rotate with the bowl and are carried out of the magnetic field to complete the sorting operation.

Product Paramenters

Model | Diameter (mm) | Tube length(mm) | Rotational speed(r/min) | Feeding size(mm) | Capacity (t/h) | Motor power(kw) |

CTB6012 | 600 | 1200 | <35 | 2-0 | 10-20 | 1.5 |

CTB6018 | 600 | 1800 | <35 | 2-0 | 15-30 | 2.2 |

CTB7518 | 750 | 1800 | <35 | 2-0 | 20-45 | 2.2 |

CTB9018 | 900 | 1800 | <35 | 3-0 | 40-60 | 3 |

CTB9021 | 900 | 2100 | <35 | 3-0 | 45-60 | 3 |

CTB9024 | 900 | 2400 | <28 | 3-0 | 45-70 | 4 |

CTB1018 | 1050 | 1800 | <20 | 3-0 | 50-75 | 5.5 |

CTB1021 | 1050 | 2100 | <20 | 3-0 | 50-100 | 5.5 |

CTB1024 | 1050 | 2400 | <20 | 3-0 | 60-120 | 5.5 |

CTB1218 | 1200 | 1800 | <18 | 3-0 | 80-140 | 5.5 |

CTB1224 | 1200 | 2400 | <18 | 3-0 | 85-180 | 7.5 |

CTB1230 | 1200 | 3000 | <18 | 3-0 | 100-180 | 11 |

CTB1530 | 1500 | 3000 | <14 | 3-0 | 170-280 | 15 |

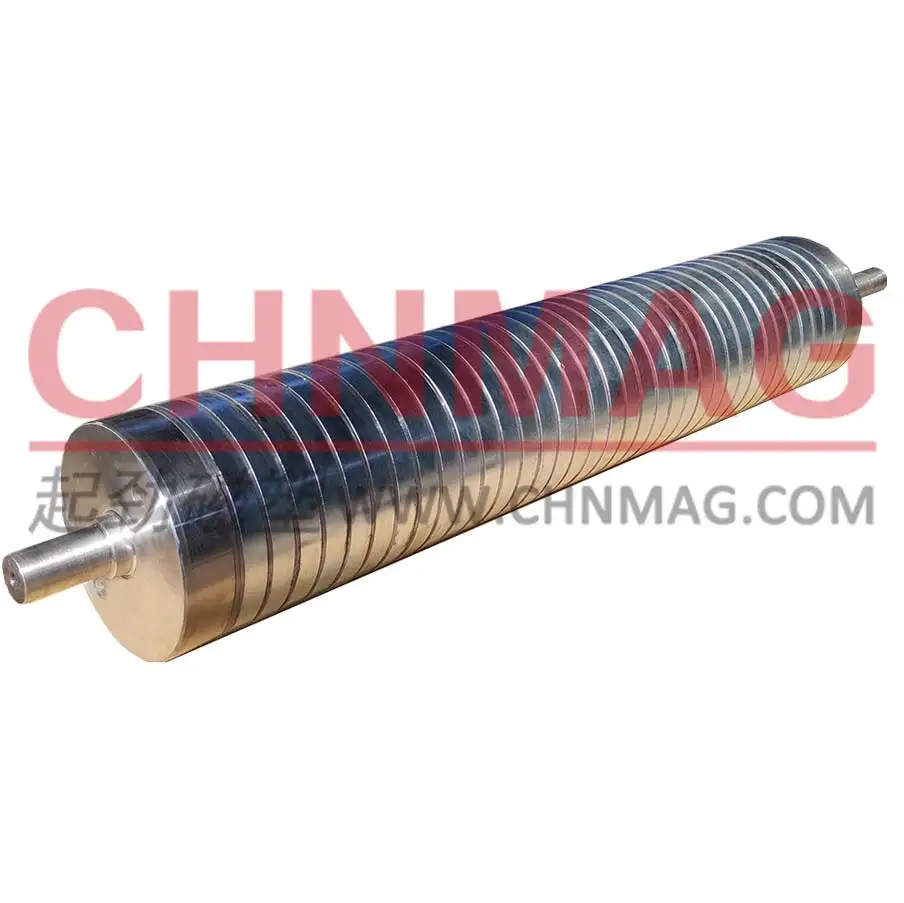

Dry magnetic separator

Model | Forms | Type (mm) | To deal with size(mm) | Processing (t/h) | Weight equipment (kg) | Overall dimensions |

B500*Φ320 | Permanent magnet magnetic roller type | Φ320*550 | 10-50 | 20 | 100 | 890*320*320 |

B500*Φ400 | " | Φ400*610 | 10-50 | 30 | 150 | 990*400*400 |

B500*Φ500 | " | Φ500*850 | 10-50 | 40 | 200 | 1050*500*500 |

B650*Φ500 | " | Φ500*760 | 10-50 | 50 | 250 | 1170*500*500 |

B650*Φ630 | " | Φ630*760 | 10-50 | 60-80 | 300 | 1170*630*630 |

Performance characteristics

Downstream magnetic separator

The direction of movement of the slurry is the same as the direction of rotation of the cylinder or the direction of movement of the product. The slurry is fed directly into the magnetic system of the cylinder from the feed box, and the non-magnetic ore particles and the ore particles with weak magnetic properties are discharged through the gap between the two bottoms under the cylinder. The magnetic ore particles are adsorbed on the surface of the cylinder, rotate with the cylinder to the weak part of the magnetic field at the edge of the magnetic system, and are unloaded into the concentrate tank by the unloading water pipe. The downstream magnetic separator has a simple structure, large processing capacity, and can also be used in series with multiple units, which is suitable for the rough separation and selection of coarse-grained strong magnetic ores with a particle size of 6~0mm, or for the recovery of magnetic heavy media.

Semi-counterflow magnetic separator

The feed slurry enters the sorting space from the bottom of the trough in a loose suspension state, and the direction of the slurry movement is basically the same as the direction of the magnetic field force, so the ore particles can reach the surface of the cylinder with a high magnetic field force. In addition, the tailings are discharged from the tailings hole in the floor so that the height of the overflow surface can maintain the slurry level in the tank. The above two characteristics determine that the semi-countercurrent magnetic separator can obtain high concentrate quality and metal recovery rate. Therefore, it is widely used for rough separation and selection of strong magnetic ores with fine particles (less than 0.2 mm). This magnetic separator can be used in series with multiple units to increase concentrate grade.

As the source factory, we are trustworthy,You are welcome to contact us!

Product packaging and delivery

Shipping

We usually use wooden case packaging, if you have special needs, you can negotiate with us for customization, we can provide a variety of packaging solutions to meet the needs of sea or land transportation. Stable seismic resistance and customized protection ensure that each piece of equipment arrives safely in your country without worry.

Company Profile

Gongyi Xiangrui Machinery Manufacturing Co., Ltd.

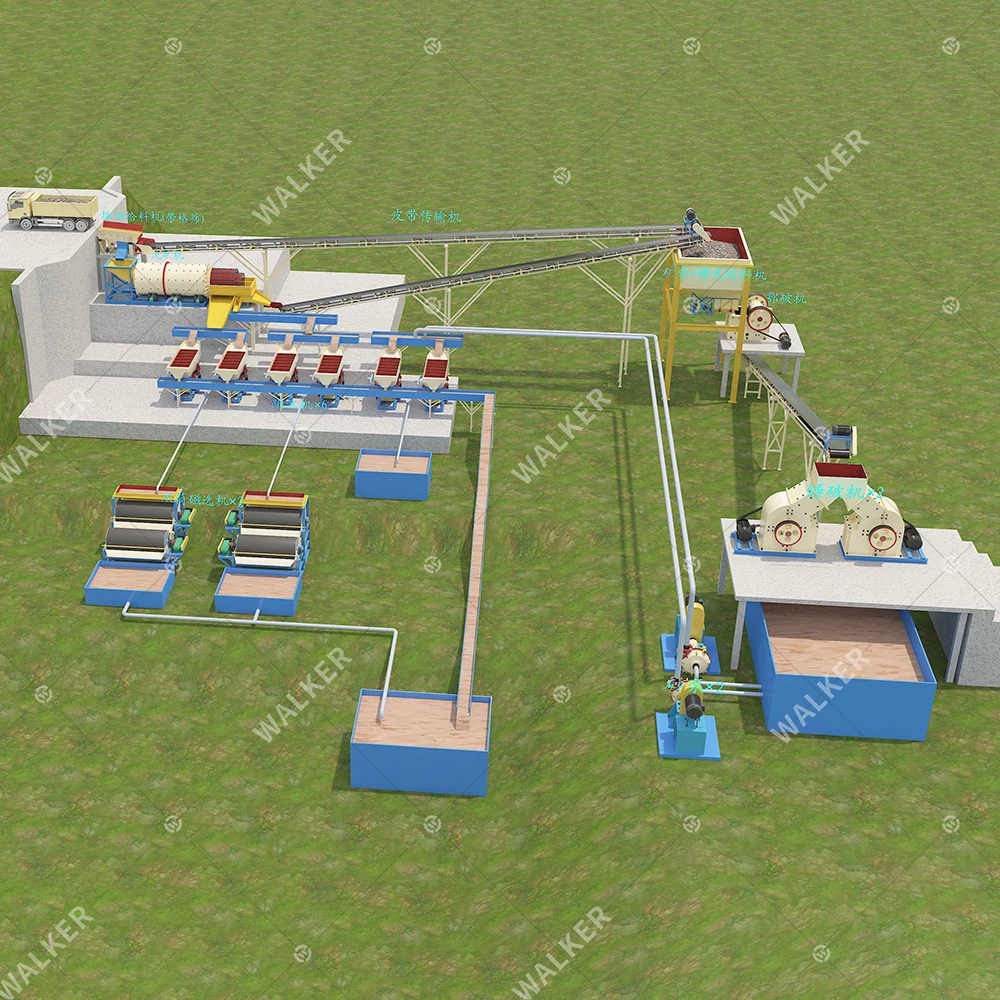

Gongyi Xiangrui Machinery Manufacturing Co., Ltd. is a large-scale manufacturing enterprise mainly engaged in the production of brick making machine machinery and heavy mining machinery, integrating scientific research, production, sales and service. The company is located in the private science and technology park of Chuangye Road, Kangdian Town, Gongyi City, Henan Province, covering an area of more than 15,000 square meters, with 6 modern heavy-duty production workshops, advanced technology and perfect production management system. After more than 20 years of development, it has been exported to Serbia, Romania, Russia, Mongolia, Indonesia, Kazakhstan, Viet Nam, North Korea, Egypt, Ghana, Tanzania, South Africa, Canada, Chile, Bolivia, Mexico and other countries and regions.

The magnetic separator, ball mill, jaw crusher, hammer crusher, impact crusher, brick/block making machine,etc. produced by the company have been successfully applied at home and abroad. All of them are tracked and tested by quality inspection engineers; And the company has passed ISO 9001:2015 international quality system certification, ISO 45001:2018 quality, health and safety management system certification, ISO 14001:2015 environmental management system certification, five-star commodity after-sales service system certification, to ensure that users are provided with high-quality and reliable equipment.

The company can provide production line design according to customer requirements. Xiangrui Machinery pursues the business philosophy of "survival by quality, development by reputation", adheres to the production policy of "not accepting defective products, not producing defective products, and not producing defective products", and all equipment from casting - machining - assembly are checked by technical engineers at all levels, and strive to build a brand enterprise that satisfies users, so that customers can buy at ease and use comfortably! It has created more value for many enterprises and society.

FAQ

1.Q: Is your company a manufacturing company or a trading company?A: We are a direct sales factory, not an agent or trading company, quality and after-sales service are guaranteed.

2.Q: How to guarantee the quality of the machines?

A: Our products have passed ISO 9001-2000 certification. We have 20 years of experience in machine manufacturing and are constantly updating our technical concepts and applications.

3.Q: When do you ship?

A: We usually ship within 10 days after we receive full payment from the buyer.

4.Q: What are the payment terms?

A: Payments under $1000 require full payment. For payments over $1000, the advance deposit is 30% via T/T and the balance before T/T shipment is 70%. Other transaction options are also available.

5.Q: Can you provide videos?

A: We can send you a video, please contact me.

6.Q: What are your warranty terms?

A: We provide 12 months warranty for all quality issues.

7. Q: How do I install and maintain the machine?

A: We can provide you with videos, emails, pictures ..... , teach you to install or maintain the machine. If it is a large project, we can arrange an engineer to your country to help you install or maintain the machine. If you need spare parts, we can provide them free of charge or at cost price, but you need to pay the courier fee.

8.Q:Allocation and training of engineers?

A: We can provide manuals, working videos, installation videos and pictures first, or we can assign engineers to go abroad to install or train machines for users.

9.Q: Do you provide customized service?

A: We can provide customized service (color, LOGO, size, material, etc.).

10.Q: Can we visit your factory?

A: Yes, you can visit our factory anytime.

OUR SERVICES

1.24 hours online service.

2.Email: xiangruimachinery88@gmail.com

3.Can be customized according to customers' requirements.

4.Please check again before shipment.

5.Ship on time.

6.We can test the machine before shipment if customers need.

7.The more you need, the cheaper the unit price.

8.Help customers to ship.

3.Can be customized according to customers' requirements.

4.Please check again before shipment.

5.Ship on time.

6.We can test the machine before shipment if customers need.

7.The more you need, the cheaper the unit price.

8.Help customers to ship.

Похожие товары

15000 Gauss Сильный магнитный ролик

2 999,00 $

Барабанная железная руда марганцевая Шахта с постоянным магнитом для удаления влажного железа

1 800,00-2 300,00 $

Золотодобывающий редкоземельный Рудный магнитный сепаратор ильменит

12 500,00-12 800,00 $

CGD220 * 1500 горное оборудование электросепаратор высокого напряжения для отбора минеральных цирконитов/аллювиальных золотых руд

42 800,00-44 000,00 $

Многокановый высоковольтный Электрический сепаратор Ильменитовый магнитный нигерийский проводящий металлический

16 000,00-16 500,00 $

Золотая всасывающая лодка для продажи речная дноуглубительная машина

3 578,00 $

Заводская Прямая продажа марганцевого завода в Abuja Нигерия

16 000,00-23 000,00 $

Новые поступления

Новинки товаров от производителей по оптовым ценам

Кокосовая стружка мягкая и сладкая на вкус без глютена запеченная Ароматизированная упаковка для приготовления пищи кондитерских

Медицинский одноразовый стерильный катетер

Эффективные акустические панели эффективные звукоизоляционные материалы для качественной

65% полиэстер/35% хлопок саржа TC камуфляжная ткань 220gsm с водонепроницаемым принтом

1,48-1,61 $

Органическое жидкое мыло для мытья рук оптом

0,66-1,46 $

Высокое качество Sunpal 450W-600W 48V фотоэлектрические солнечные панели 500W 500Wp 600W заводская цена с белой задней простыней

0,28-0,32 $

2025 руиба новый продукт зажим для пуповины оптовая продажа медицинский стерильный одноразовый пластиковый

Оптовая продажа индивидуальные синие 3-слойные одноразовые маски для лица хирургические медицинские защитные взрослых

40-41,80 $