Машина для прессования сухого порошка хромированной руды с черным алмазным брикетом по доступной цене оборудованные компоненты сердечника коробки передач двигателя

- Категория: >>>

- Поставщик: Henan Lanyu Machinery Equipment Co. Ltd.Henan Ltd.

Сохранить в закладки 1601367089414:

Описание и отзывы

Характеристики

Chrome Ore Dry Powder Press Machine with Black Diamond Briquette Affordably Priced Equipped Engine Motor Gearbox Core Components

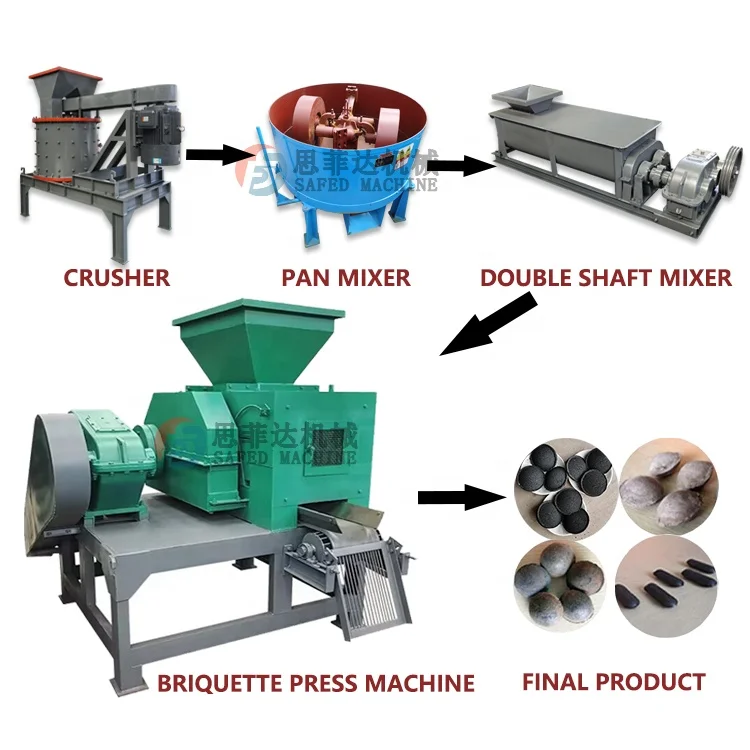

This paper delves into the creation of mineral powder briquette machinery, which is a device used to produce briquettes from various types of ore powder materials. Primarily, the equipment is utilized for briquette creation, as well as forming of several kinds of ore powder materials, such as iron ore powder, which is a byproduct of grinding and magnetic separation processes applied to diverse iron ore varieties. The term "ore powder" refers broadly to the powder form of materials produced from the processing of ore, with different iron content levels after the ore undergoes grinding and magnetic separation processes. Its application is deeply rooted in the ambit of the national energy-saving and emission reduction project as it plays a significant role in the recovery and utilization of materials and environmental protection. In summary, the benefits of utilizing mineral powder briquette machinery stretch beyond just its application to large, medium, and small-sized enterprises requiring production lines. Its various uses span across different industries like industrial gas, boiler types, cold briquette production, ignition briquette making, civil metallurgy, refractory materials, and even the medical industry. The quality of the ore powder ball briquettes is robust, and the machine boasts multiple features, making each product a reliable and versatile solution to various industrial needs, all of which contributes to the efficient utilization of materials and environmental conservation.

The ore powder ball briquette has been used and improved in industry for many years. Compared with other similar products, the ore powder ball briquette has obvious advantages, such as high ball forming rate, low power consumption, compact structure, easy maintenance and adjustment, and so on. The working principle of the ore powder ball briquette plays an important role in the molding process, and the wheel is the core part of the equipment. The diameter of the two wheels is the same, the axis is parallel to each other, and there is a certain gap. Hemispherical fossa with regular arrangement, uniform shape and same size on the wheel. When the motor began to run, the pair of wheels began to rotate at the same speed and in the opposite direction. When the material passes through the joint of this pair of wheels, it is subjected to briquette and the volume is briquette ed. With the continuous rotation of the wheel, the ball socket is closed slowly, the material is also subjected to greater force, and the volume is further briquette ed. When the ball-socket distance is short, the ball-socket reaches a large forming briquette . Subsequently, the wheel rotation gradually increased the distance between the ball socket, the forming briquette gradually decreased, to achieve the goal of smooth ball.

Ore powder ball briquette to the requirements of molding materials: 1, the size of the material in 80 mesh 200 mesh. 2. No metal should be allowed in the material, otherwise the roller surface will be damaged. 3, the material must be satisfied, so that the rate of spheroidization requires the technical personnel to remind the user that when briquette a ball with metal ore powder, the wear of the roller skin is rather severe, and the user should pay special attention to the material of the roller skin when purchasing the ore powder briquette machine. Good choice of wear-resistant alloy forging.

Briquette machine can be used to suppress pulverized coal, iron, coal, aluminum, iron, iron oxide, carbon powder, charcoal powder, slag, gypsum, tailings, sewage sludge, kaolin, activated carbon, coke powder and other powder, powder, waste, waste residue, and it’s widely used in refractory, metallurgical, chemical, electric factory, energy, transportation, heating and other industries.

Briquette machine can process raw materials into corresponding pillow, oval, round or square shaped end products.

Working principle of ball press machine

1. Raw material is transferred onto two pressure rollers of ball press machine through feeder.

2. Raw material enters the ball roll mode with the roll rotation.

3. Material pressure on a small part become larger, when the material enters into the two pressure rollers, the pressure of materials has reached the peak.

4. Tremendous pressure between the two rollers, the powder become finished product.

Performance Features

Briquette machine is mainly used for the pelleting of powdery materials that are difficult to be pressed and it has such features as high pelleting pressure, adjustable rotating number of the main engine and configuration of spiral feeder machine.

The Materials Size Requests for Briquette machine

In order to ensure the good quality and mechanical strength of the final product, special care should be taken to ensure that the granule size fed to the machine is maintained below 3mm, preferably in the range of 30-40% smaller than 1–2 mm, with no more than 10% over 2 mm.

Briquette machine can suppress all kinds of powder materials like magnesia, bauxite, dolomite, iron powder, lignite, coal powder, iron powder, coking coal, aluminum, iron, tin oxide, carbon powder, coal powder, slag, gypsum, tailings, sludge, kaolin clay, activated carbon, coke, etc, with forced pressurization method

Who we are

Established in 1980, Henan Lanyu Machinery is a professional the sawdust briquette machine manufacturer based in Henan Province. Every year, we exported hundreds of the sawdust briquette machine to Sudan, Egypt, and Zimbabwe etc.

l What we do

We are specialized in manufacturing and exporting different models of the sawdust briquette machine, carbonization equipment and many other related the sawdust briquette machineproducts.

l Why us

We use stringent quality control measures to ensure the reliability of our products. Our products including the sawdust briquette machine have gained CE and ISO 9001 certificate guarantee. With sound business credit, rich experiences, excellent after-sales services and modern manufacturing facilities, we’ll cooperate with and serve you better.

Q1: Can you test our sample raw materials on your ball press machine?

Yes, we are very happy to receive your sample materials for testing and analysis.

Q2: Do you provide equipment operation training for your customers?

Yes. We can send professional engineers to your site for equipment installation and commission, also giving operation and maintenance training. We could also provide training online to your staff. The third option is sending you videos to guide you on installation and operation.

Q3: Could you offer the complete wood working flow chart?

A: Yes, we will allocate suitable production chart according to your special requirements, such as crusher, wood hammer mill, carbonization furnace, ball press machine, dust-removal device, auto-feeding conveyor, discharging conveyor, and control cabinet etc.

Q4: Where is your factory located? How to get there?

A: We are located in Zhengzhou city, Henan province, China. The nearest airport is Zhengzhou Xinzheng International Airport, and the Airport Code is CGO. We will pick you up at airport. Welcome to visit our factory anytime.

If you require further information about ball press machine, please feel free to contact me. Welcome to visit our factory anytime!

Похожие товары

Древесный уголь шаровой пресс

Машина для изготовления брикетов

Заводская цена автоматическая брикетировочная машина различные характеристики шаровой пресс антрацитовый брикет для прессования шариков

Заводская Низкая Цена Опилки палочки опилки биомассы древесного угля брикетировочная машина

Машина для брикетирования кофейных древесных опилок цена Филиппин

Машина для прессования металлических стружек

Машина Для Брикетирования Древесных Опилок с низкой интенсивностью работы

Новые поступления

Новинки товаров от производителей по оптовым ценам