12 л/мин Электрический 12 В постоянного тока мини маленький поршневой насос маленький вакуумный насос для продажи

11,50 $ - 12,50 $

Сохранить в закладки 1650298649:

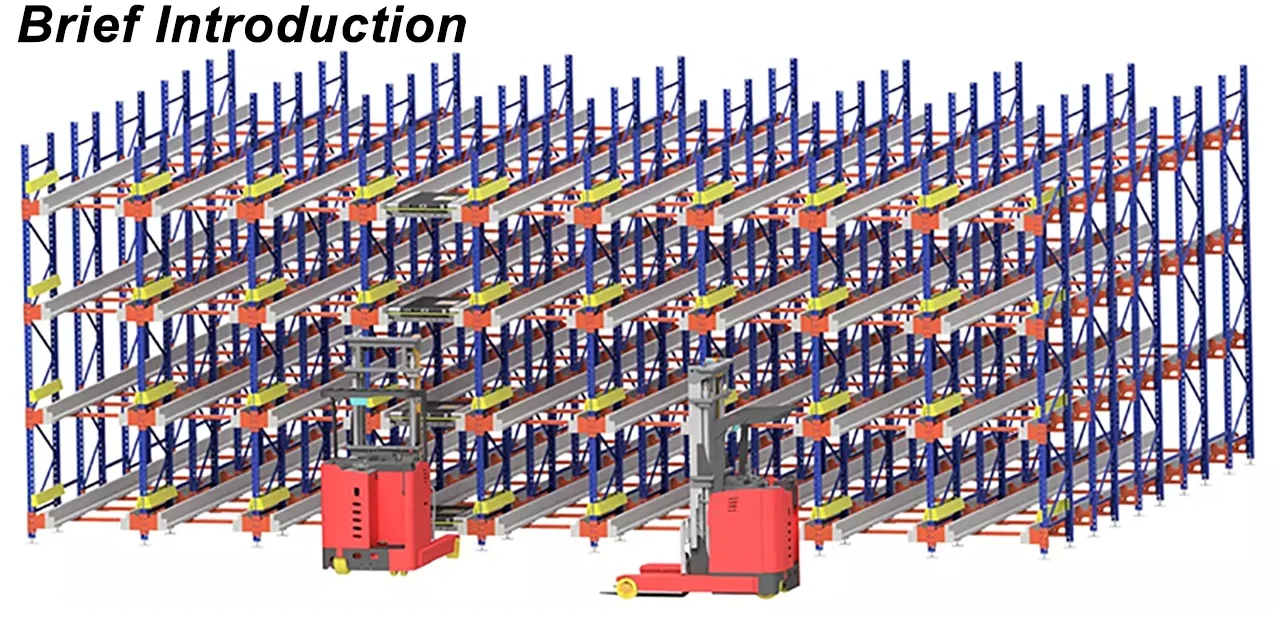

Name | Radio shuttle system | Material | Q235a | ||

Size | Customized Size | Color | Customized | ||

Depth | Customized | Weight Capacity | 500~5000kg | ||

Width | Customized | Height | Customized | ||

Finish | Powder Coated | ||||

Usage | Warehouse Storage System | ||||

Packing | Customers' Request | ||||

Certification | AS4084-2012 /CE/ ISO/RMI | ||||

Free Sample | Available (Delivery Cost on Buyer) | ||||

OEM | Available | ||||

Новинки товаров от производителей по оптовым ценам