1500w CNC Fiber Laser Cladding

- Категория: >>>

- Поставщик: Jinan Senfeng Laser Technology Co. Ltd.Jinan Ltd.

Сохранить в закладки 1700001051248:

Описание и отзывы

Характеристики

Product Description

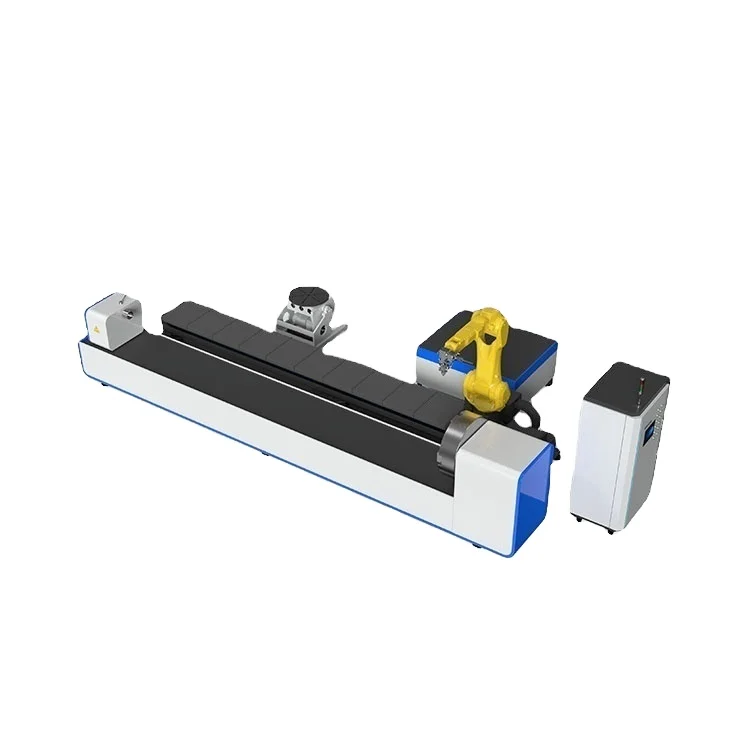

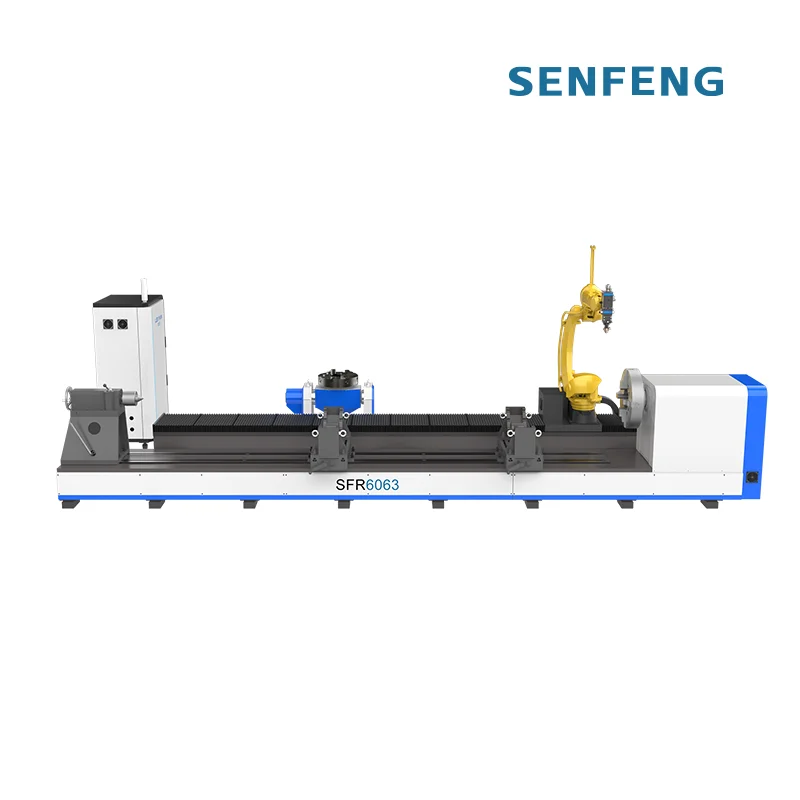

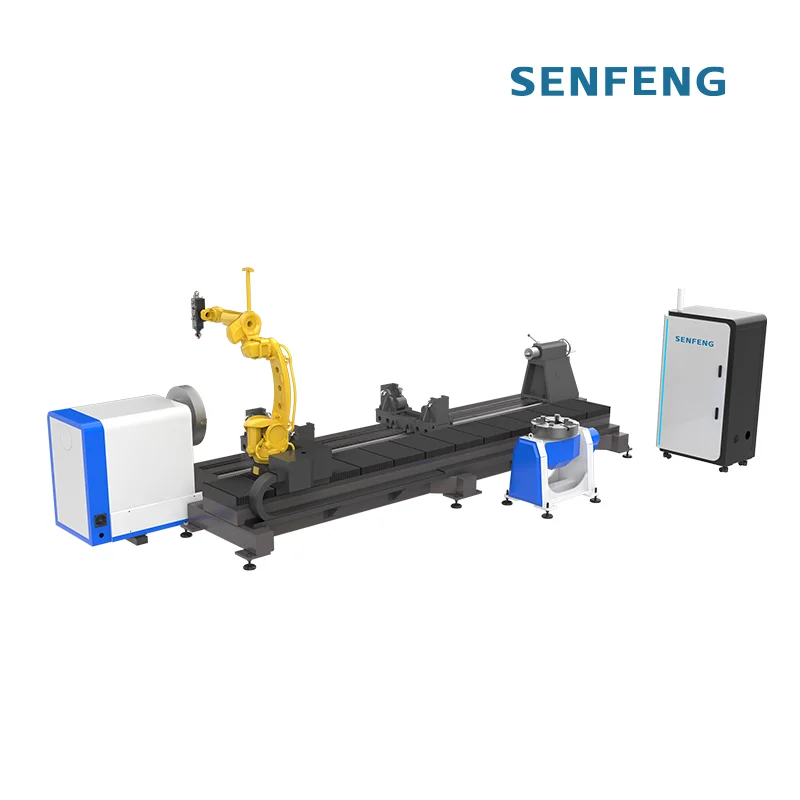

SFR6063 is a large-scale repair and surface remanufacturing system based on industrial six-axis robot and slide rail. The system comprises a high-efficiency fiber laser with a process head, powder feed system, horizontal rotary table, biaxial positioner and man-machine interface control system integrated with a 6-axis motion robot. The equipment has complete functions, diverse performances and strong versatility, which can realize the cladding of shaft surface, curved surface and special-shaped parts. Cooperating with the powder feeder independently developed by Senfeng, the cladding materials, and related processes can be flexibly selected for size repair, surface treatment, and strengthening.

Product Advantages

Fast cooling speed

The cooling rate is up to 106k/s, which belongs to the rapid solidification process, and it is easy to obtain a fine-grained structure or a new phase that cannot be obtained in equilibrium, such as an unstable phase and an amorphous phase.

Low coating dilution

The low dilution of the coating can obtain a good coating with a low dilution rate, and the coating composition and dilution can be controlled.

Wide cladding thickness

The thickness range of cladding layer is wide. The coating layer can reach 0.2-2.0mm in a single pass of powder feeding.

Product Features

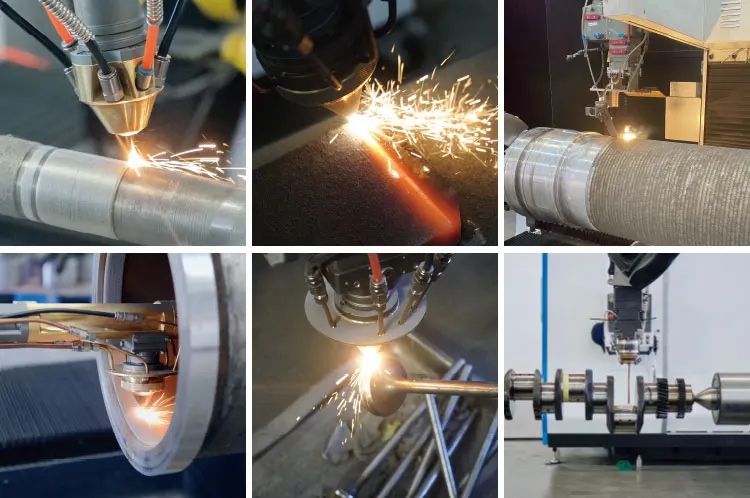

The laser cladding technology performs laser cladding on the alloy powder on the surface of the substrate to make the surface complex physical and chemical metallurgical processes have been carried out on the surface gold combination, thereby improving and repairing the surface performance of the workpiece.

Application

Laser cladding technology has a wide range of applications, almost covering the whole machinery manufacturing industry, mainly including mining machinery, petrochemicals, electric power, railways, automobiles, shipping, metallurgy, aviation, machine tools, power generation, printing, packaging, mould and other industries.

After Sales Service

AFTER-SALE SERVICE

1)The seller provides one time free installation and training in buyer’s factory. Seller pays for the airplane tickets and salary for engineers, buyer should provide accommodation and food to engineers.

2)The seller will provide technical guide’s e-mail, telephone, Wechat, Whatsapp and so on.

3)The seller should pay for the travel expense if local service needed within warranty time.

2)The seller will provide technical guide’s e-mail, telephone, Wechat, Whatsapp and so on.

3)The seller should pay for the travel expense if local service needed within warranty time.

Company Introduction

SENFENG LASER is a professional manufacturer engaged in the research, development, production, sale and service of laser cutting systems,fiber laser cutters, fiber laser cleaning machine, laser cladding machine,laser welding machine and 3D robot.

SENFENG LASER has 7 standardized laser equipment manufacturing bases with a total area of more than 120,000 square meters. Company employs more than 950 people, has many sets of fully automated production equipment, has strict production process, annual output can reach 5000 sets.

SENFENG LASER has 7 standardized laser equipment manufacturing bases with a total area of more than 120,000 square meters. Company employs more than 950 people, has many sets of fully automated production equipment, has strict production process, annual output can reach 5000 sets.

Похожие товары

3 резервуара машина для производства слякошек напитков с профессиональным вращением коммерческого

1 210,00-1 295,00 $

Высокоскоростной Платиновый 3 Длина волны 755 808 1064 нм диодный лазер для продажи CR-D7/808 высокой мощности машина удаления

311 283,00-372 519,00 ₽

Disposable Visual Endoscopic Suction Cannula with Optical Camera for Surgical

Sus Sanitary Pneumatic Keystone Wafer Butterfly

Стоматологическая лаборатория Алмазная отделка фрезерный бокс

5,30-5,50 $

Manufacture Price Pumpkin Seeds Separating Harvester Separator

3 950,00-3 999,00 $

2016 оптовая продажа деревянная лошадка-качалка для девочек новый дизайн корова игрушки

Новые поступления

Новинки товаров от производителей по оптовым ценам

Светлая Золотая морская солнечная энергия ландшафтное украшение постмодерн минималистский стиль чистая ручная роспись маслом 24x3 1 дюйм/60x80

35-53 $

Европейские антикварные простой Последние двойной металлической кровати

Автоматизированная складская система автоматического хранения в Гуанчжоу Eyda с эффективными стеллажами и

10 000-35 000 $

Декоративный чехол для PS5 Сменный Чехол консоли пластины Playstation5 пылезащитный с защитой от царапин

7,50-7,70 $

Лучшее качество детские подгузники для сухих подгузников новорожденных размер 2 4 и большие доставка или

3 $

Выключатель для формованного корпуса Schneider NSX100N 50KA AC 3P3D 25A TMD новая модель C10N3TM025

Буф2-.. М .. Краны

Оптовая продажа высококачественный сублимированный клубничный порошок Заводская поставка

5,50-6,40 $