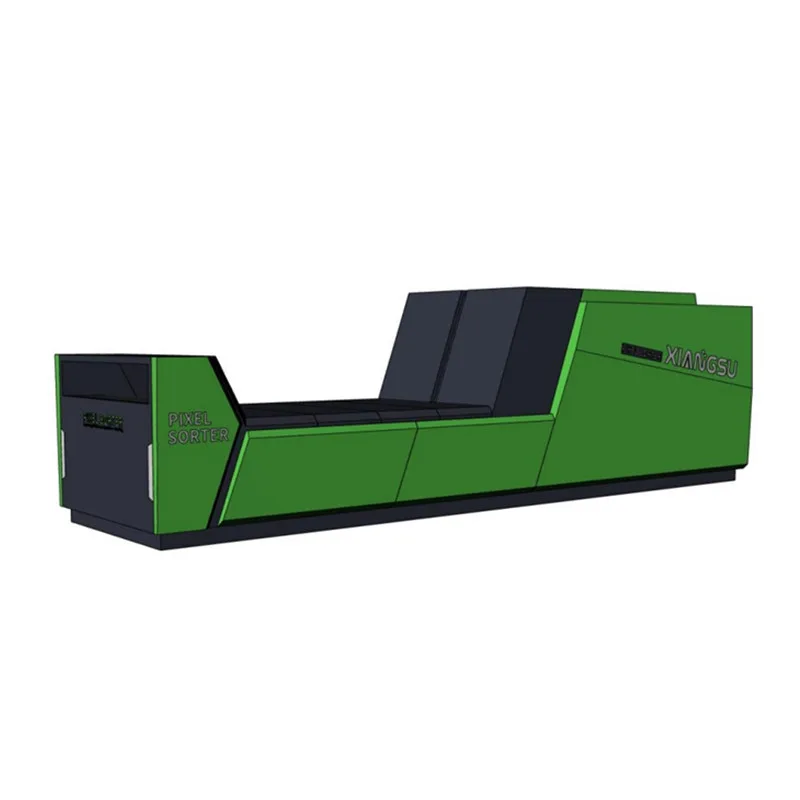

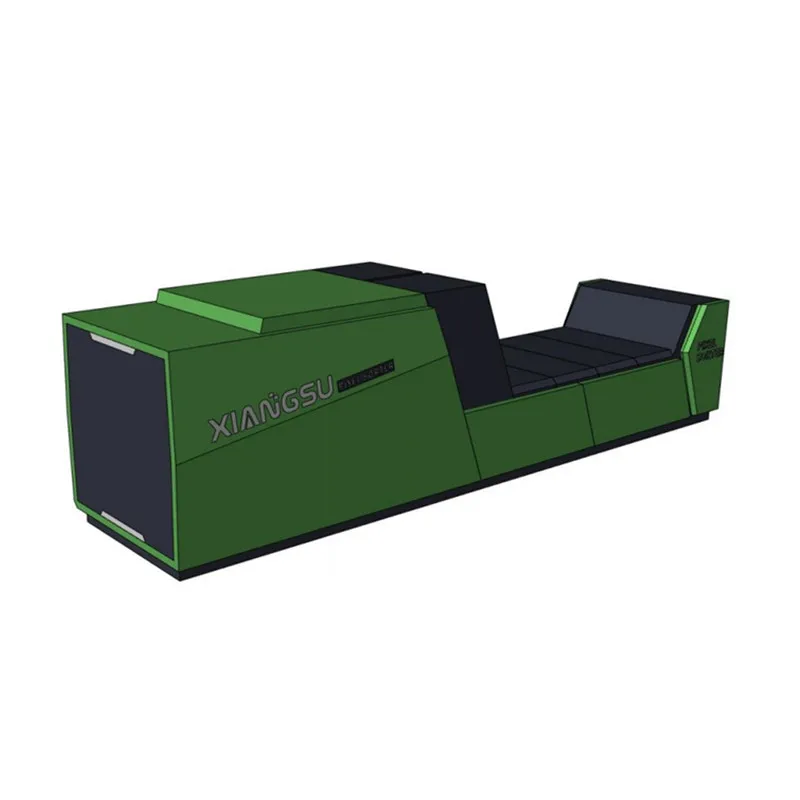

Интеллектуальная система сортировки для разделения руды XRT рентгеновский Сухой Тип TDS уголь и минералы на основе датчика

- Категория: >>>

- Поставщик: Tangshan Xiangsu Intelligent Technology Co. Ltd.

Сохранить в закладки 1700004465963:

Описание и отзывы

Характеристики

Product Application

Tangshan Xiangsu Intelligent Technology Co., Ltd. is a professional technology-based enterprise engaged in the development of intelligent sorting equipment. Our company is mainly committed to providing our partners with overall R&D services and software solutions for high-speed XRT sorting equipment.

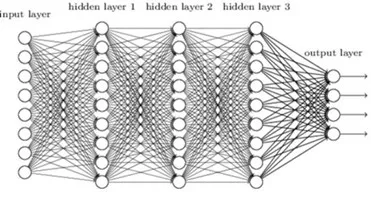

Our company has a group of highly educated and professional talents team whom have focused on the development of software and hardware for intelligent XRT sorting equipment for more than 5 years, we have developed a number of software and hardware products with independent intellectual property rights. They have rich practical experience in the fields of X-ray sorting and image sorting.

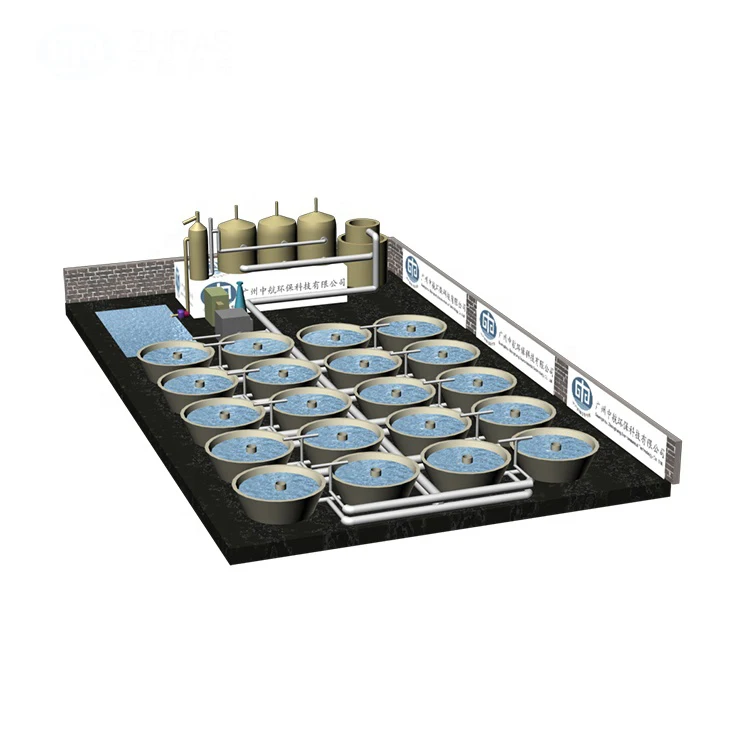

The intelligent sorting system can easily sorting ores automatically without queuing in high speed and high accuracy. It is widely used in the sorting of various ores such as coal, diamond, tungsten, tin, rare earth, antimony, copper, lead, zinc and the renewable resources of stainless steel, aluminum, magnesium, circuit boards, etc .

\t | |||

\t | \t | \t | \t |

\t | \t | \t | |

\t | \t | \t | |

\t | \t | \t | \t |

\t | \t | \t | |

\t | \t | \t | |

Main Technology

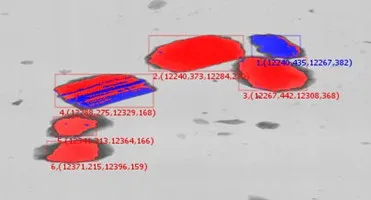

1) X-ray transmission recognition technology: X-rays penetrate the recognized object, due to different substances have different absorption rates of rays, the dual-energy X-ray sensor measures the X-ray energy penetrating the recognized object, which can ignore the thickness of the measured object , and measure the density of the measured object accurately. Xiangsu Intelligent Technology uses innovative technology-through a special algorithm can easily identify the density of the substance without completely penetrating the object under test, which has an accuracy rate of more than 99%.

2) Accurate blowing clock synchronization technology: synchronize the clocks of multiple sensors to ensure high-speed synchronization of the recognition and execution system.

3) High-speed solenoid valve synchronization technology: the solenoid valve is calibrated and individually calibrated to ensure the blowing quality.

4) Finished product density measurement technology: real-time measurement of the finished product density through a set of sensors, real-time monitoring of the finished product quality.

5) Radiation source calibration technology: calibrate the radiation source to ensure the uniformity of the radiation and reduce the debugging time after replacing the radiation source.

Application

INDUSTRIAL MINERAL SORTING

Calcite, Dolomite, Feldspar, Limestone, Magnesite, Quartz Sorting, Rare Earth Elements, Rocksalt, Talc

Benefits: Contaminants can be removed early in the separation process, reducing crushing and classification costs, increasing recovery and enhancing deposit exploitation.

Application

FERROUS METAL SORTING

Iron, Manganese, Chrome

Benefits: Separating coarse low grade material before it enters further comminution and sorting processes decreases cost and increases productivity significantly.

Application

SLAG METALS SORTING

Ferro Silica Slag, Ferro Chrome Slag, Non-Ferrous Slag

Benefits: Reducing metal content through effective sensor-based sorting enables producers to sell safe slag products as aggregates and grinding media.

Application

NON-FERROUS METAL SCRAP SORTING

Copper, Tungsten, Nickel, Gold Sorting, Platinum, Silver

Benefits: Effective removal of contaminants that impair the flotation and leaching processes accelerates recovery and therefore revenue.

Pre-Sales Service

* Inquiry and consulting support.

* Free sample testing support.

* View our Factory & Lab.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

\t | |

\t | \t |

\t | \t |

\t | \t |

Products Name with link

91.8% Response Rate

Products Name with link

91.8% Response Rate

Products Name with link

91.8% Response Rate

Похожие товары

15hp Лодочный мотор 2-х тактный лодочный подвесной двигатели лодочные моторы 15

320x240 ЖК-дисплей 3,5 дюймов TFT LCM 54pin ЖК-модуль с RGB интерфейсом

Горячая Распродажа OEM завод под заказ прочное оборудование для рециркуляции креветок аквакультуры Крытая рыболовная ферма система

Пластиковая ловушка для аквакультуры, для вертикальной системы, клетка для разведения омаров, крабов, коробка для аквакультуры

Пластиковый колпачок для ключей

Оптовая продажа, прямая цена с завода, тренировочный ручной пистолет из резины и пластика для подготовки к настоящему оружию

Серьги с золотым покрытием, серьги в европейском и американском стиле, модные серьги для женщин, ювелирные изделия, трендовая подвеска

Новые поступления

Новинки товаров от производителей по оптовым ценам