24 тонны/24 часа машина для сушки чипсов konjac с тепловым насосом производства муки porang

- Категория: >>>

- Поставщик: Sichuan Jieneng Drying Equipment Co. Ltd.

Сохранить в закладки 1700007541920:

Описание и отзывы

Характеристики

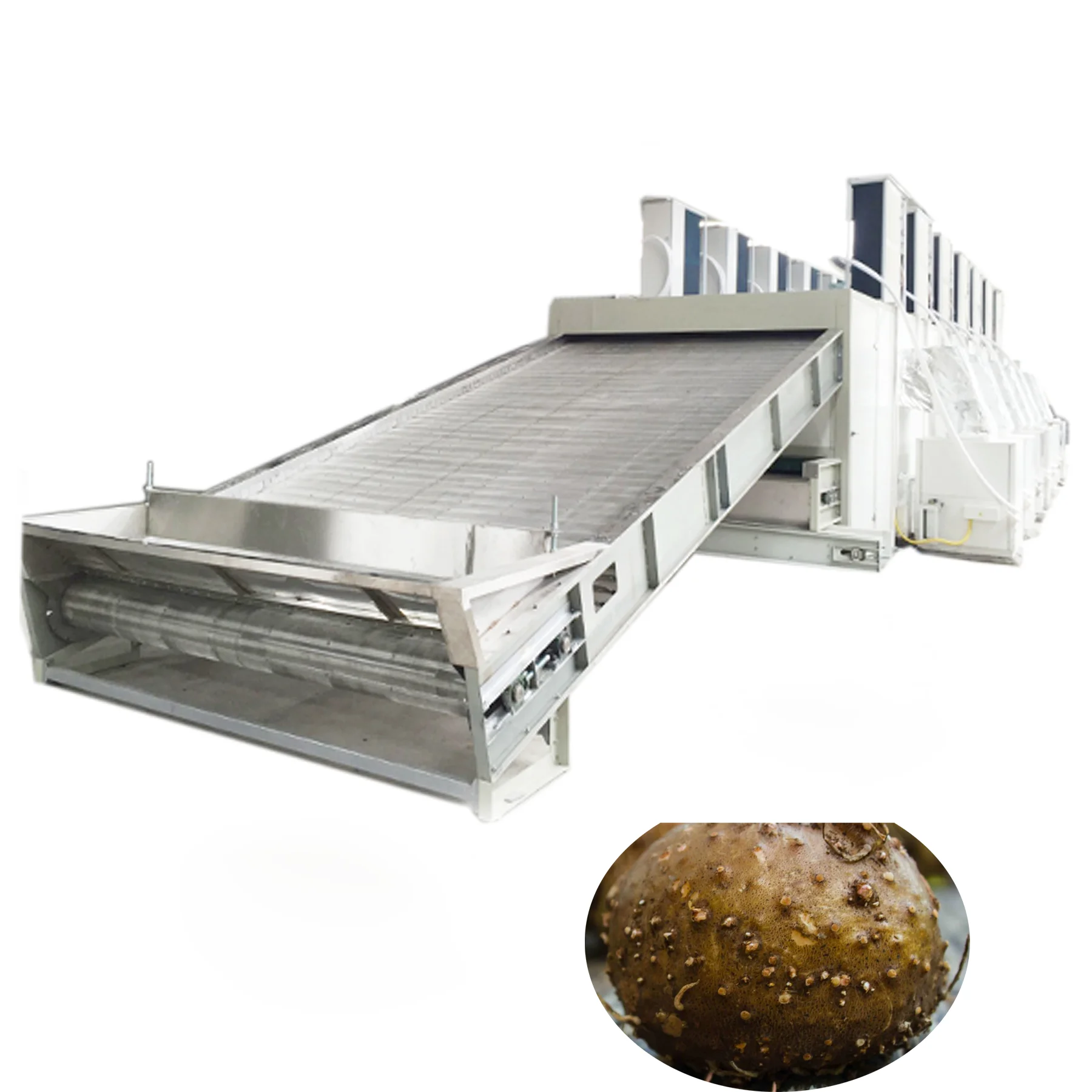

24 tons/24hrs konjac tuber chips dryer machine with heat pump for konjac powder processing

1, fresh konjac washing and peeling, remove bud and root.

2, slicing and color fixing (optional, SO2 agent)./ Perajang

3, Drying machine, PLC control, and layered temperature zone

4, sorting & grading.

5, crushing & grinding

( 40-120 meshes, glucomannan no less than 65%)

6, pulverizing the flour to get konjac micro powder

( >120 meshes, glucomannan >75%)

7, inspection & packaging.

Model | JN-konjac 24T |

Overall Dimension (mm) |

27044*3820*3845 |

Drying area |

effective drying area 210 square meters |

Layers | 5 |

Power (Kw) | 125 |

Heat source | CNG |

Drying period (h) |

about 6 hours |

Capacity (t/24h) | 24 |

Похожие товары

ФЛУОРЕСЦЕНТНОЕ Отбеливающее средство, сушилка с распылителем жидкой формы, гранулятор кипячения, марганцевый сульфат, влажный спрей, гранулятор

Сушилка для банановых ягод, лиофилизатор, Вакуумная сушилка для пищевой промышленности

Специализированная промышленная сушилка из нержавеющей стали для бычьего навоза, одиночная вращающаяся трубка, барабанная сушилка, сушильная машина

Конкурентоспособная цена, двойная коническая вращающаяся Вакуумная сушилка для фармацевтической промышленности

Промышленный сельскохозяйственный тепловой насос с холодным воздухом, сушилка для колбасы, говядины, еды для домашних животных

Промышленная сушилка для лотков с циркуляцией горячего воздуха

Лабораторная вакуумная сушильная печь промышленная сушилка

Новые поступления

Новинки товаров от производителей по оптовым ценам