Промышленная машина для сушки чипов konjac с CNG производства порошка glucomanan

- Категория: Drying Oven >>>

- Поставщик: Sichuan Jieneng Drying Equipment Co. Ltd.

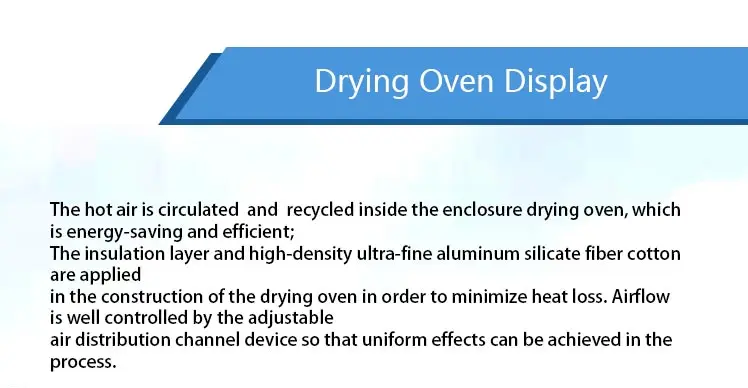

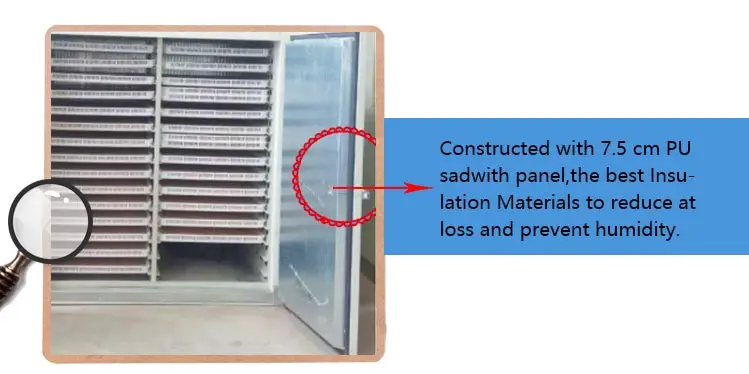

Сохранить в закладки 1700007602990:

Описание и отзывы

Характеристики

industrial konjac chips drying machine with CNG for konjac glucomannan powder processing

We offer various capacities for konjac tuber chips

drying machine for common konjac flour (konjac

fine powder) and konjac gum (konjac micro

powder). This dry milled method is traditional

and widespread.

1, fresh konjac washing and peeling, remove bud and root.

2, slicing and color fixing (optional, SO2 agent).

3, Drying machine, PLC control, and layered temperature zone.

4, sorting & grading.

5, crushing & grinding

( 40-120 meshes, glucomannan no less than 65%)

6, pulverizing the flour to get konjac micro powder

( >120 meshes, glucomannan >75%)

7, inspection & packaging.

Model | JN-T1 | JN-T2 | JN-T3 | JN-T4 | JN-T5 |

Drying area (m2) | 7.5 | 14 | 29 | 43 | 56 |

Effective volume (m3) | 1.3 | 2.6 | 4.9 | 7.4 | 10.3 |

Drying capacity(Kg/batch) | 60 | 120 | 240 | 360 | 480 |

Fan air volume (m3/h) | 3450 | 3450 | 6900 | 10350 | 13800 |

Fan power(KW) | 0.55 | 0.55 | 0.55×2 | 0.55×3 | 0.55×4 |

Dryer dimension(mm) | L1400 W1200 H2160 | L2260 W1200 H2160 | L2260 W2160 H2160 | L3280 W2160 H2160 | L4350 W2160 H2160 |

Trolley | 1 | 2 | 4 | 6 | 8 |

Tray | 24 | 48 | 96 | 144 | 192 |

Weight (Kg) | 480 | 1080 | 1520 | 1960 | 2400 |

Похожие товары

Машина для обработки фруктов, оборудование для сушки бананов, сушилка для бананов

Китай, индивидуальная одноразовая сушилка для грибов для промышленных овощей, фруктов, Дегидратор

Тепловой насос для сушки, легкая установка манго, сушилка для благовоний, сушилка для продуктов, сушилка для продуктов

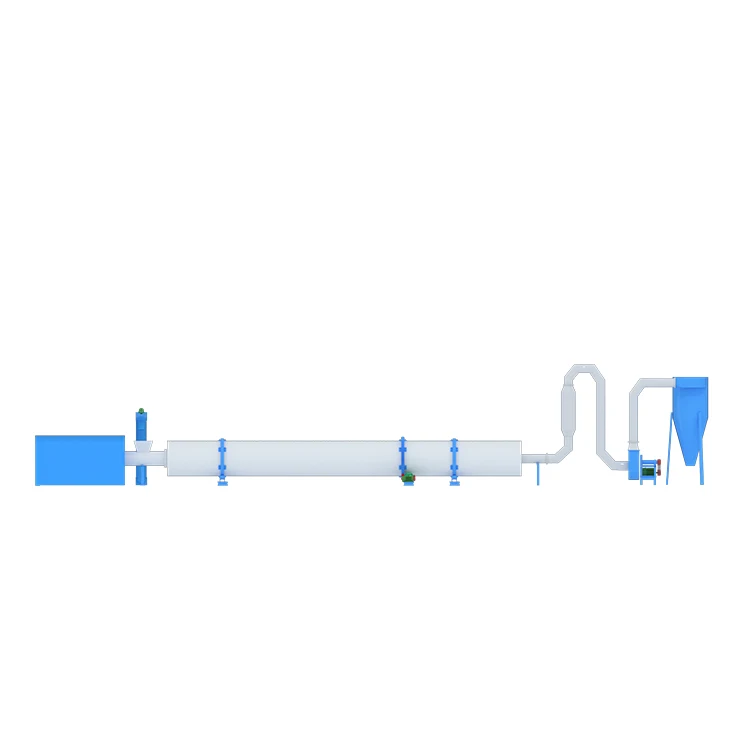

Песчаная вращающаяся сушилка вращающаяся барабанная фляжка сушилка энергосберегающее поворотное устройство сушильная машина

Высокотемпературная вращающаяся цилиндрическая барабанная сушилка для силикагель песок коричневый уголь древесные опилки вращающаяся барабанная сушилка

Вращающаяся барабанная сушилка, Высокоэффективная сушилка для нагревательного барабана, энергосберегающая вращающаяся барабанная сушилка

revolving cylinder drum dryer wood chips sawdust energy saving flaker dryer

Новые поступления

Новинки товаров от производителей по оптовым ценам