Портативный небольшой гидравлический вертикальный Лидер продаж автоматическая идентификация металлических ленточно пильный станок контактная электросварочная

- Категория: Band Saw Machines >>>

- Поставщик: Changge Deleixi Machinery Equipment Co. Ltd.

Сохранить в закладки 1700008031587:

Описание и отзывы

Характеристики

Product Description:

| Band saw sawing machine products | |

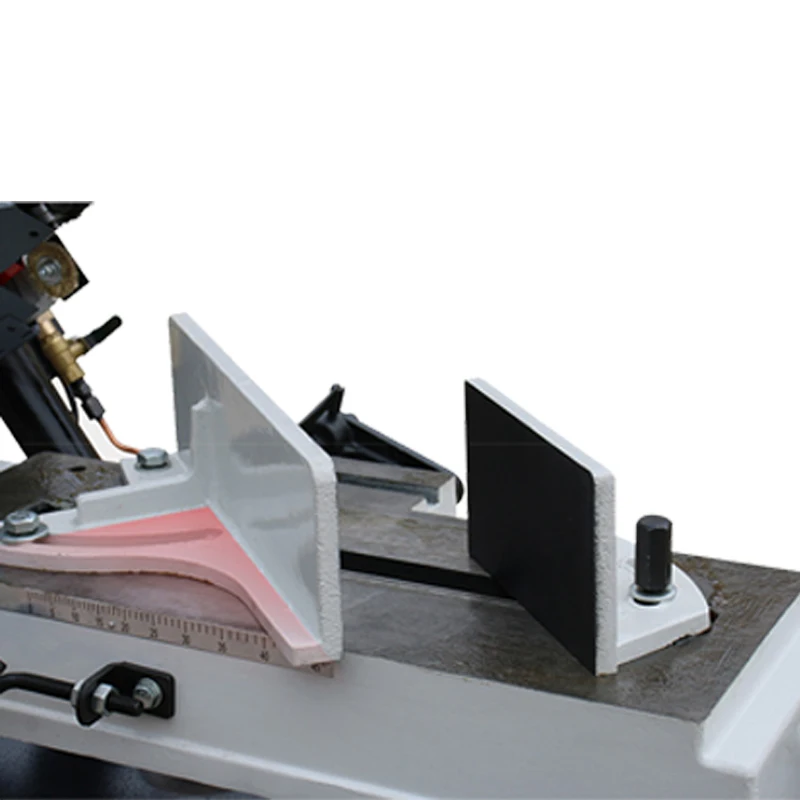

| Type | 5 inchMetal Band Saw Machine |

| model | GW5013 |

| Motor voltage | 220V/380V |

| Motor Power | 750W |

| Saw blade size | 1638*13*0.65MM |

| Sawtooth | 8 teeth/inch |

| Square material cutting size | 150*125MM |

| Round material cutting size | 125MM |

| Square material 45° cut | 95*75MM |

| Round material 45° cut | 95MM |

| Square material 60° cut | 55*55MM |

| Round material 60° cutting | 55MM |

| Cutting speed | 20/29/50M/min |

| Cutting angle | 0-60° |

| Package dimensions | 950*450*550MM |

| weight | 90/92KG |

| Type | 7 inch metal band saw machine | 8 inch metal band saw machine |

| model | GWA5018 | GWA5018 |

| Motor voltage | 220V/380V | 220V/380V |

| Motor Power | 1100W | 1100W |

| Saw blade size | 2360*20*0.9MM | 2360*20*0.9MM |

| Sawtooth | 8 teeth/inch | 8 teeth/inch |

| Square material cutting size | 300*180MM | 215*205MM |

| Round material cutting size | 180MM | 205MM |

| Square material 45° cut | 180*110MM | 100*200MM |

| Round material 45° cut | 110MM | 150MM |

| Cutting speed | 34/41/59/98M/min | 34/41/59/98M/min |

| Cutting angle | 0-45° | 0-45° |

| Package dimensions | 1260*460*1080MM | 1240*570*1140MM |

| weight | 150/170KG | 165/195KG |

This machine, portable, easy-to-use, 3-speed bandsaw is an excellent choice for small or large projects where you must cut a variety of metals, plastics, or wood. When the vertical cutting attachment is installed, the saw is able to make vertical cuts for your unique cutting requirements.

Packing and Shipping

1. Packaging: 1)Wrapped by proctective film;

2)Packed by standard import & export wooden cases or carton boxes.

2. Shipping: By logistics; by automobile; by train; by shipping; by air etc.

Electric Hydraulic High Efficiency Automatic Rebar Stirrup Bender Rebar B

ending Machine

Cnc Cheap Price Mechanical Automatic Rebar Roller Rebar Steel Wire Straightening And Cutting Machine

Changge Deleixi Machinery Equipment co. LTD is a manufacturer of processing machine our products include steel bar cutting machine,steel bar bending machine,straightening cutting machine,stirrup bending machine,plate compactor,tamping rammer ,trowel machine and so on, with well-equipped testing facilities and strong technical force.With a wide range, good quality, reasonable prices and stylish designs, our products are very popular in Mid-east,Africa,European ,American .ect, they are widely used in building ,road,railway and other area.Our products are widely recognized and trusted by users and can meet continuously changing economic and social needs.We welcome new and old customers from all walks of life to contact us for future business relationships and mutual success!

Cnc Cheap Price Mechanical Automatic Rebar Roller Rebar Steel Wire Straightening And Cutting Machine

1.We have more than10 years manufacture and export experience.

2.Exporting to all over the world,win high reputation among customers.

3.CE, ISO 9001 and Strict Production Guideline to guarantee the high quality of our products.

4.Near the Qingdao port convenient for exporting.

5.Customer service staff 24 hours online,offer free technical support.

6.Factory and Competitive Price we offer.

7.Strong Research & Development technical team.

8.Various machinery to meet all your needs at our factory.

9.Engineers are available to guide the installation and take care of other problems.

10.We offer OEM&ODM service to meet all your requirements.

Cnc Cheap Price Mechanical Automatic Rebar Roller Rebar Steel Wire Straightening And Cutting Machine

1) How can I place order?

A: You can contact us by email about your order details, or place order on line.

2) How can I pay you?

A: After you confirm our PI, we will request you to pay. T/T (HSBC bank) and Paypal, Western Union are the most usual ways we are

using.

3) What's the order procedure?

A: First we discuss order details, production details by email or TM. Then we issue you an PI for your confirmation. You will be

requested to do pr -epaid full payment or deposit before we go into production. After we get the deposit, we start to process the

order. We usually need 7-15days if we don't have the items in stock. Before production has been finished, we will contact you for

shipment details, and the balance payment. After payment has been settled, we start to prepare the shipment for you.

4)How do you take care when your clients received defective products?

A: replacement. If there are some defective items, we usually credit to our customer or replace in next shipment.

5)How do you check all the goods in the production line?

A: We have spot inspection and finished product inspection. We check the goods when they go into next step production procedure.

Похожие товары

TGK-4240 TTMC вертикальный токарный станок с ленточная пила горизонтальная металлическая для резки машины 400 мм круглый автомат адвокатского

BS912 ленточная пила для резки металла горизонтальный гидравлический станок цена

GZ4232 Высококачественная Автоматическая Горизонтальная ленточная пила с

Горизонтальная ленточная пила GH4235

SH-H BS-712N, профессиональное изготовление, производство горизонтальная мини ленточно-пильный станок для обработки металлов

Профессиональный производитель ленточная пила для резки металла машина алюминия на 45

Сверхмощная ленточная пила, режущая машина для H-образного луча

Новые поступления

Новинки товаров от производителей по оптовым ценам