Студенты медики практикуют только кривые щипцы Мэриленда

- Категория: >>>

- Поставщик: Hangzhou Haizhu MIM Products Co. Ltd.Hangzhou Ltd.

Сохранить в закладки 1775461221:

Описание и отзывы

Характеристики

maryland forceps hangzhou laparoscopic instruments china

| Brand | HZMIM |

| Model | LP1105 |

| Application | maryland forceps |

| Quality | ISO |

| Surface | bright |

| Material | 17-4ph |

| Plating | nickel/zinc/chrome/silver |

| Shape | irregularity |

| Type | dissector |

| Dimension | diameter 5mm, lenth 330mm |

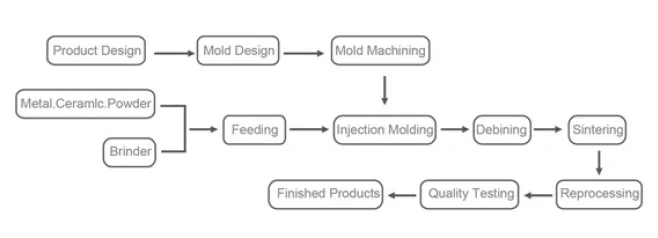

What's Metal injection molding (MIM) ?

Metal injection molding (MIM) is a metalworking process where finely-powdered metal is mixed with a measured amount of binder material to comprise a 'feedstock' capable of being handled by plastic processing equipment through a process known as injection mold forming. It is an effective way to produce complex and precision-shaped parts from a variety of materials.

It is common for this process to produce parts for 50% less than the cost of CNC machining or investment casting. At the same time, and excellent surface finish in combination with high volume manufacturing capability.

Total cost savings result from the function of shape complexity, production volumes, size of the part, and material used. Sizes of parts can be up to 150 grams,although most parts produced are less than 30 grams.

Why choice MIM?

Parameter | MIM | COVENTIONAL PM | MACHINING | INVESTMENT CASTING |

Density | 98% | 88% | 100% | 98% |

Tensile Strength | High | Low | High | High |

Elongation | High | Low | High | High |

Hardness | High | Low | High | High |

Complexity | High | Low | High | Medium |

Surface Finish | High | Medium | High | Medium |

Production Volumes | High | High | Low | Medium |

Range of Materials | High | High | High | Medium-High |

Cost | Medium | Low | High | Medium |

Flexible jaw design:

medical grade stainless steel(17-4PH) jaws

Jaw opening angle is big, effective grasping

Screw-thread structure design:

easy to be assembled and disassembled, higher fastness

Rod customized:

available in length customized

Various kinds of jaws:

complete range of jaws such as grasping forceps, dissectors, scissors, needleholders, and many more

Circle platform of mount design (thickness 0.35mm):

reduce friction, flexible operation

Hangzhou Haizhu MIM products co., ltd. Has been specializing in metal injection molding (MIM), ceramic injection molding (CIM) and magnet for decades.

Our product line including: tools, medical treatment, hardware, ceramic parts, electronic appliance, automobile parts, consumer products, spinning parts and so on. Over 95% of our products are exported to German, United States, Middle East etc.

As the company grew, HZMIM showed its greatest strength:

• Accumulating experience and expertise in designing, manufacturing and marketing.

• Perfect quality control system

• Rich development experience and manufacturing process

• Complete sales service network

We are striving toward excellence and continuously improve product quality, response speed, customer service and our competitiveness in the market.

We always deliver competitive high-quality products and supply excellent services for our global customers.

Our factory

We supply custom-made precision spare part.

Complete supply chain, advanced fabrication facilities.

Offer prototype or 3D samples after designing to see if it meets customer’s requirements.

Perfect quality control system, our products passed ISO9001 & ISO13485 certification.

Rich experience, we can give you professional advice.

Powder injection molding, CNC Machining, Casting, Die Casting, ect. | |

Material | Low alloy steel, Stainless steel, Carbide, Ceramic, Heavy Alloys, Titanium, Magnetic Materials, ect. |

Dimension of custom-made parts | Length<100mm |

Workshop to produce custom-made parts | Mold workshop, injection workshop, Debinding & Sintering, Post treatment. |

Finishing Services |

|

Postprocessing services | Heat treatment, Ultrasonic cleaning, Passivation, Surface Finishing. |

Certification | ISO9001, ISO13485, TS16949 |

Quality Control equipment | Pin Gauge/Microscopy/ Dynamometers/ Hardness Tester/Torque Rheometer/Precision balances/Impact Test Equipment/ LECO Carbon Analyzers/Metallographic Equipment/Density Measurement equipment/Density measurement equipment/DCC Coordinate Measuring Machines/Advanced surface Characteristic Instruments ect.

|

Ensure that your parts meet defined critical specifications.

We have many instrument and test equipment to inspect the products.

Pin Gauge/Microscopy/ Dynamometers/ Hardness Tester/Torque Rheometer/Precision balances/Impact Test Equipment/ LECO Carbon Analyzers/Metallographic Equipment/Density Measurement equipment/Density measurement equipment/DCC Coordinate Measuring Machines/Advanced surface Characteristic Instruments.

Похожие товары

Оси вала из хромированной стали сплава изготовленные на заказ для велосипедных вентиляторов велосипедов трициклов

Осевой вал IED500120 Передний левый для Range Rover полный размер L322

Токарные станки с ЧПУ

CNC OA вал обработки под заказ из нержавеющей стали ось поворотный

Высококачественный полуосевой приводной вал с левой стороны для DFM Dongfeng S30 H30 поперечный 1 5 6

OEM CNC механический вал приводная ось шасси стальная для радиоуправляемого самолета

Услуги по обработке CNC машинное оборудование для автокамер быстрое прототипирование ABS нейлоновый токарный станок обработанный

Новые поступления

Новинки товаров от производителей по оптовым ценам