Автоматическая стальная пластина IGBT с ЧПУ индукционная закалка машина для закалки

- Категория: Прочие промышленные машины и оборудование >>>

- Поставщик: Chengdu Duolin Electric Co. Ltd.

Сохранить в закладки 1924892920:

Описание и отзывы

Характеристики

IGBT automatic cnc induction hardening machine for quenching

Product Detail

Technique Parameters

Model | SSF-30 | SSF-50 | SSF-60 | SSF-80 | SSF-120 | SSF-160 | |

Rated Power Output (KW) | 30 | 40 | 60 | 80 | 120 | 160 | |

Working Frequency (Khz) | 10-30 | 10-30 | 10-30 | 10-30 | 10-30 | 8-15 | |

Power Capacity (KVA) | 38 | 50 | 75 | 100 | 150 | 200 | |

Input Power | 380V/50Hz 3 phase 4lines | ||||||

Working Voltage | 342V-430V | ||||||

Input Current (A) | 48 | 63 | 97 | 135 | 195 | 240 | |

Cooling | Power Unit L/min(0.1Mpa) | 27 | 32 | 40 | 33 | 56 | 56 |

Transformer L/min(0.1Mpa) | 26 | 29 | 41 | 32 | 68 | 68 | |

Weight | Power Unit (KG) | 39 | 60 | 68 | 99 | 130 | 140 |

Transformer (KG) | 29 | 34 | 53 | 63 | 88 | 120 | |

Dimension | Power Unit | 365*500*790 | 405*505*860 | 400*540*970 | 750*500*1040 | 550*600*1380 | 550*600*1380 |

Transformer | 320*320*310 | 320*360*310 | 410*470*385 | 410*470*385 | 405*555*380 | 810*410*440 | |

Feature

1.Frequency&case hardening depth&diameter, the below sheet for reference

| Case depth(mm) | Bar diameter(mm) | Frequency(KHz) |

| 0.8 to 1.5 | 5 to 25 | 200 to 400 |

| 1.5 to 3.0 | 10 to 50 | 10 to 100 |

| >50 | 3 to 10 | |

| 3.0 to 10.0 | 20 to 50 | 3 to 10 |

| 50 to 100 | 1 to 3 | |

| >100 | 1 |

2.Can heat Carbon steel, Stainless steel, Alloy steel

3.Quick water connections

4.IGBT inversion technology &LC series circuit design achieve energy saving up to 15%-30% compared with SCR technology

automatic machine

5.Diode rectification technologies ensure high power factor-more than 0.95

6.Phase-locked technology &perfect protection system enhance good reliability of machine

7.PLC or CNC vertical is available

8.Color and language printed according to customer's request

Advantage

1.Rapid precise heating minimises distortion

2.Improved impact/wear resistance and tensile/fatique strength from surface hardening with core properties retained

3.Accurate control of depth and extent of heating

4.Repeatable, versatile, cost effective

5.Less interference to other equipment in the workshop

Application

Supplier of accessories

Certification

1.Reply the email within 24 hours

2.6 staffs work for Export Department,two of them have experience in sales, installing and after-service more than seven years

3.0n-site engineering service

4.12 months warranty

5.Color, language and logo can be printed according to your demands

6.Plywood cases customized for sea transport

1. How many years it can work?

Many factors, usually 5-10years, depends on your operation, cooling water, maintenance. etc

2. How many days we got the spare parts?

Usually send out in 1-2days.

Похожие товары

Распродажа, высокоточная мышь с распылителем, автоматический ПЗС-датчик зрения

Санитарная посуда, литейная машина высокого давления для двухкомпонентного шкафа с корпусом чаши, выдвижной в конструкции скользящей рамы

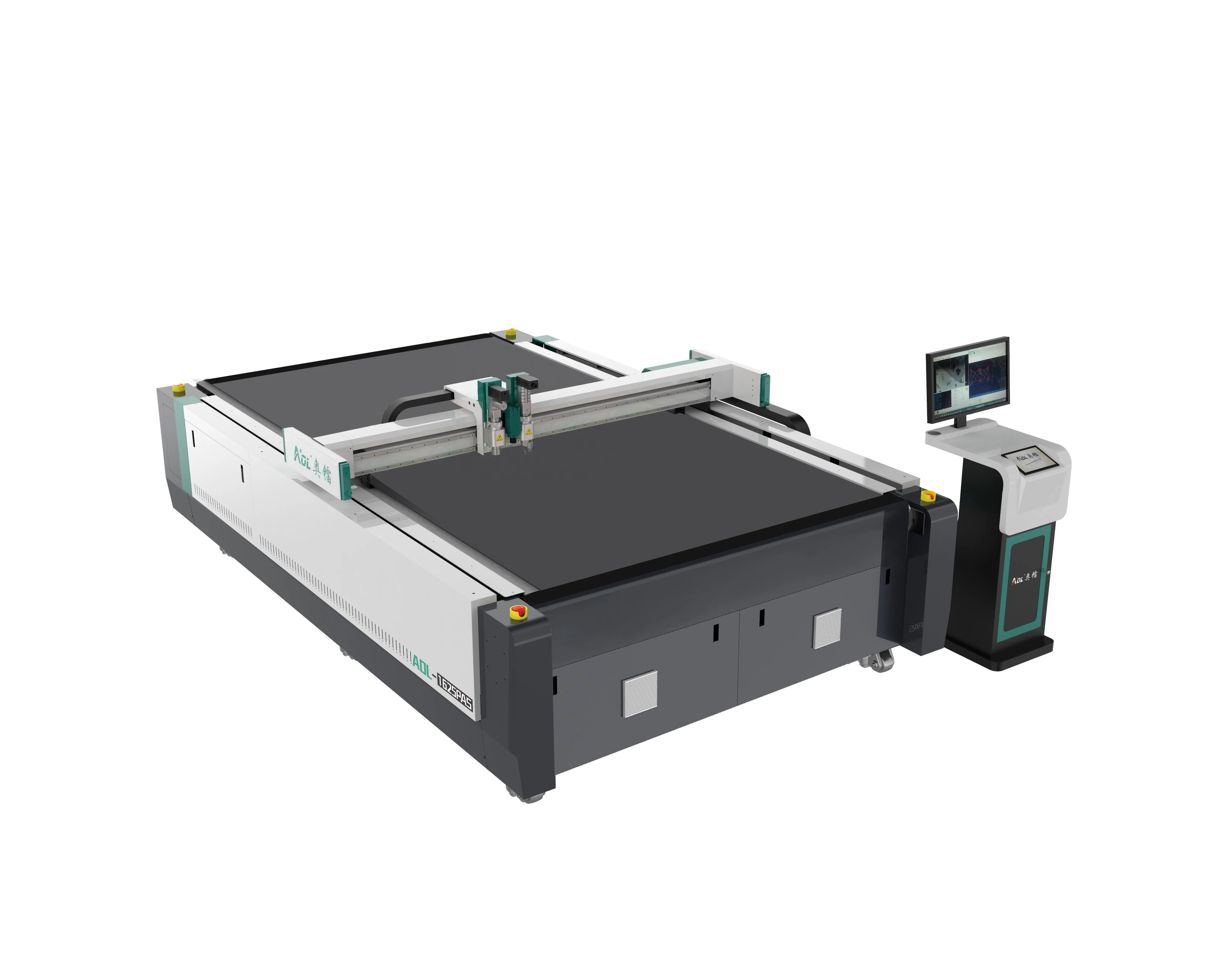

Автоматический плоттер для резки прокладок aol

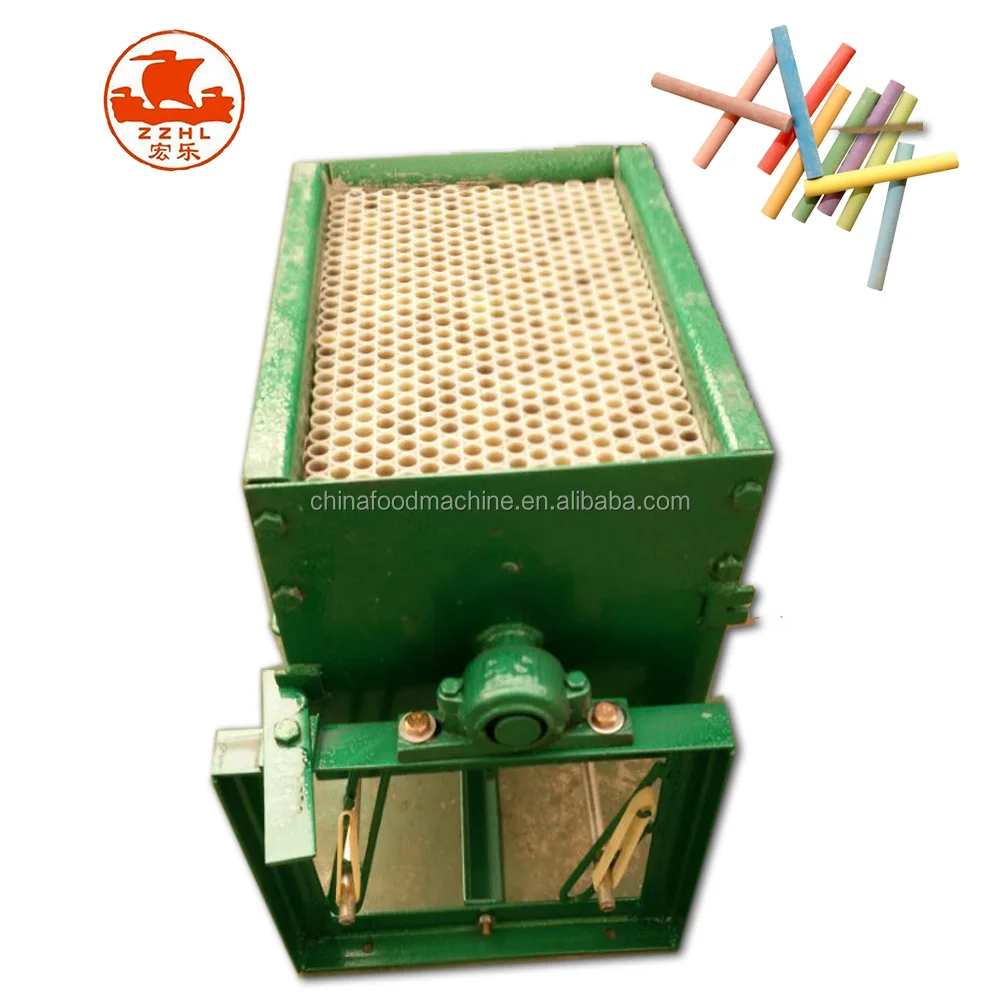

Машина для производства школьного мела без пыли

Гидрогелевая машина для резки пленки SUNSHINE 890C Mini

2017, новый тип, школьная доска, Меловые детали, формовочная машина, цена, Китай, распродажа

Автоматический фиксированный винт для мобильного телефона, настольный автоматический винтовой замок, фиксирующий станок с двойным винтом sys, затягивающий станок

Новые поступления

Новинки товаров от производителей по оптовым ценам