Литьевая пресс форма под заказ наборы кузовов из стекловолокна FRP кузов автомобиля

- Категория: >>>

- Поставщик: Shanghai Olimy Co. Ltd.

Сохранить в закладки 1968247186:

Описание и отзывы

Характеристики

Procedure of hand lay up process:

| Mould treatment:

Polish: Moulds must be polished before production. This will guarantee the good and solidified surface |

| Fiberglass and resin:

Gel coat: The color is decided by the gel coat,with thickness of about 0.3-0.5mm. UV resistant can be added.

Surface mat: This is to avoid the air bubble on the surface, and also make fiberglass mat invisible from the finished surface.

Fiberglass mat: Normally we use 300g/m2 (0.6mm thickness) and 450g/m2 (0.9mm thickness). Accordig to your requests on the thickness and strength,we will calculate how many layers of fiberglass mat should be used.

|

| Demould and trim: Solidify: The time required for solidifying depends on thickness and weather condition.Normally 24 hours for one piece to solidify to avoid any deformation after demoulding.

Demould: After solidified,we will get out the product from the mould

Cut and trim: We will mark the trim line and hole positions on the mould,then trim according to the marks to gaurantee the mounting dimensions

|

Quality Control

Our principle: Safe and economical

Packaging: 1.Air bubble packaging

2.Plywood Crate or shelf packaging

3.Carton packaging

We choose economical packaging on condition that there will be no damage during transportation.

Shipping: We are very glad to get the freight cost information for you as we have forwarders which have been cooperated for a long time.

Our workshop

Why choose us

1) 8 years' experience in fibrglass product trading, have good knowledge on process, quality control, request on different products, ready to offer international service for you.

2) Complete production line from fiberglass sheet to mould and finished products,which keeps a better quality control and will also save cost for you.

3) Hydraulic Press Machines with capacity from 60 to 2000 tons, which enable us to make products with maximum projection area of 4 square meters, so that we can meet your different size requirements.

4) 150km away from Shanghai Port, which will shorten the delivery time and save freight cost for you.

Related Products:

|  |

|  |

Похожие товары

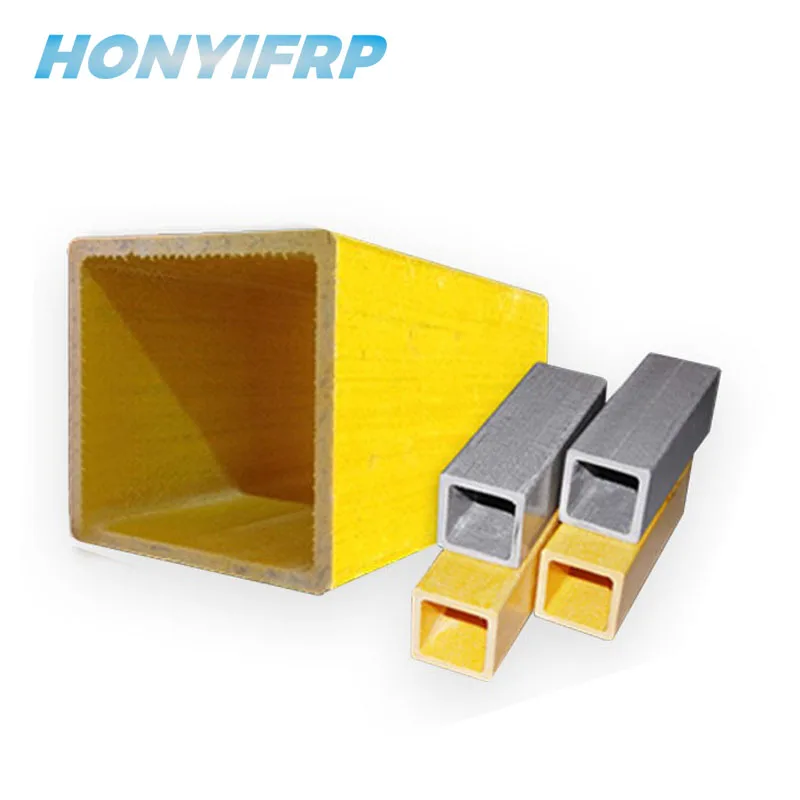

Распродажа по низким ценам, прочная и антивозрастная машина для пултрузии Frp для строительной промышленности

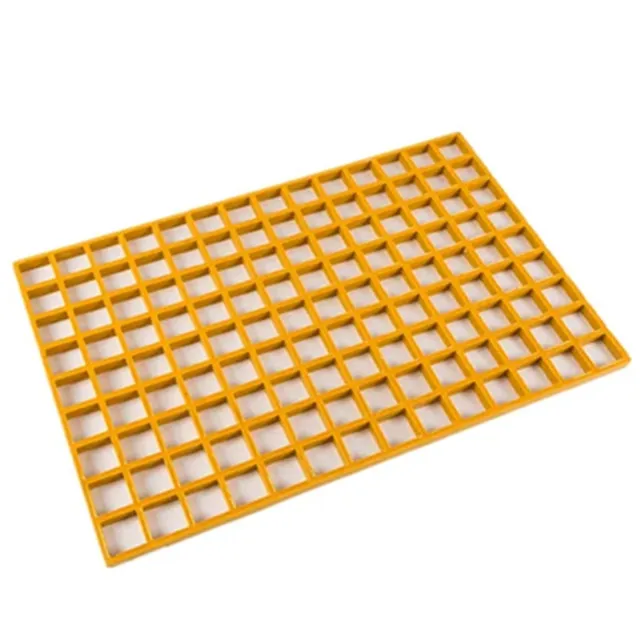

Лидер продаж, стекловолоконная дорожная решетка frp

Туннельная огнеупорная декоративная панель, огнеупорная декоративная панель для туннельных стен

420gsm печать материал безопасности дорожного движения, люминесцентное свечение, отражающие солнечные Lona alpargata баннер

Чехол для геймпада Joy Stick для PS4 по оптовой цене

Автомобильные Внешние аксессуары panal parrilla, аксессуары для пикапа, внедорожный гриль, автомобильный бампер, гриль, подходит для Escape 2008 - 2012

Заводская Оптовая Продажа Универсальная кованая втулка

Новые поступления

Новинки товаров от производителей по оптовым ценам