FT/GG 064 средней длины с хорошей обратной связью светодиодное освещение Полюс

- Категория: Высокомачтовые светильники >>>

- Поставщик: Yixing Futao Metal Structural Unit Co. Ltd.

Сохранить в закладки 212754714:

Описание и отзывы

Характеристики

FT/GG-064 Middle High Mast Lighting pole

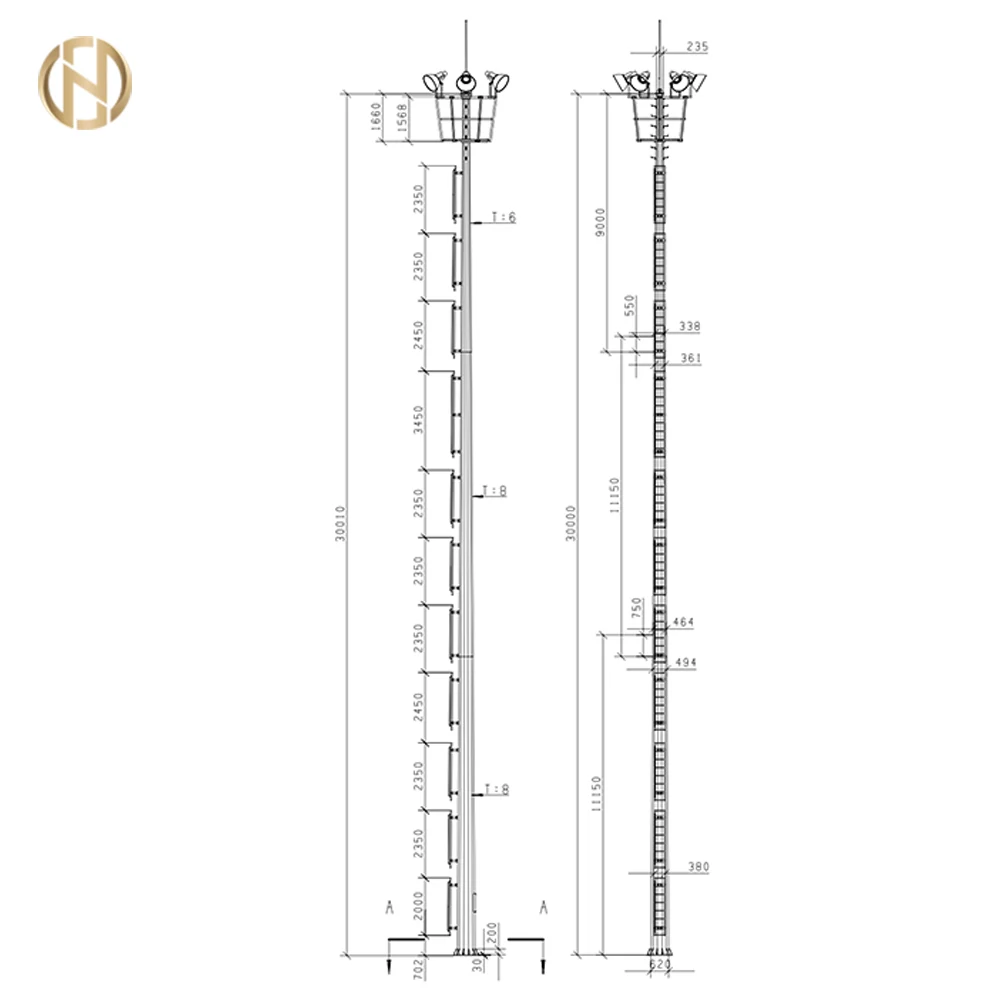

1.Design standard:AASHTO standard

2.Wind speed: more than 30M/sec

3.Anti-seismic design: more than level 7

4.Mast material:ASTM A572 GR65/Q345/Q235/GR50

5.Mast structure: 8/12/16/20 sided

6.Mast assembly: no welding on site

7.Anti-corrosion protection: hot dip galvanization/hot dip galvanization and powder coating

2.Lighting fixture

The entire lighting fixture is constructed from aluminum alloy, formed by die casting, with protection degree more than IP65.high pressure sodium lamp and metal lamp are designated lighting source, and their power range is from 250W to 2000W.lighting fixtures design is calculated by professional simulation program ,and customization is still available.

3.the crown

The primary function is to fit lighting fixtures for illuminating.

All crowns are constructed form high-quality steel ,and both inner and outer surface are processed by hot-dip-galvanization.

4.the raising-and-lowering system

1.The raising-and-lowering system is core part of the raising-and-lowering galvanized steel high mast flood lighting pole ,so that guarantees the safety and reliability of operating.

2.The raising-and-lowering system mainly consists of lighting rod,closed mast-top assembly, latching mechanism, crown, steering assembly, bumper, cables, winch, motor, lighting control cabinet, raising-and-lowering control cabinet and so on.

|

Height |

From 8 m to 45m |

|

Suit for |

Airport ,seaport,plaza,stadium ,square,highway,street way etc |

|

Shape |

Conoid ,Multi-pyramidal,Columniform,polygonal or conical |

|

Material |

Usually Q345B/A572, Q235B/A36,As well as Hot rolled coil from Q460 ,ASTM573 GR65, GR50 ,SS400, SS490, to ST52- |

|

Lamp power |

200 W- 2000 W (HPS/MH) 220V (+-10%) /50Hz |

|

Surface treatment |

Hot dip galvanized Following ASTM A 123, color polyester power or any other standard by client required. |

|

Joint of Poles |

Insert mode,innerflange mode,face to face joint mode |

|

Design of pole |

Against earthquake of 8 grade |

|

Length of per section |

Within 14m once forming without slip joint |

|

Welding |

We has past flaw testing.Internal and external double welding makes the welding beautiful in shape Welding Standard :AWS ( American Welding Society ) D 1.1 |

|

Thickness |

1 mm to 30 mm |

|

Production Process |

Rew material test → Cuttingj →Molding or bending →Welidng (longitudinal )→Dimension verify →Flange welding →Hole drilling →Calibration →Deburr→Galvanization or powder coating ,painting →Recalibration →Thread →Packages |

|

Packages |

Our high Mast Octagonal Steel Pole as normal cover by Mat or straw bale at the top and bottom ,anyway also can following by client required ,each 40HC or OT can loading how many pcs will calculation base on the client actually specification and data. |

|

Product name |

hexagonal high mast lighting pole 20m price |

fWe have certificates for BV, SGS and ISO9001.

Похожие товары

Суперъяркое наружное водонепроницаемое прожекторное освещение IP66, светодиодное спортивное освещение для стадиона

Светодиодная лампа для стадиона VAKESUN, высокая мощность, лучшее качество, 300 Вт, 400 Вт, 500 Вт, 800 Вт, светодиодная лампа для стадиона

ALLTOP алюминиевое литое освещение для аэропорта ip65 smd 200 Вт встроенное все в одном светодиодное солнечное освещение высокой мачты

Фонарь для стадиона 1600 Вт, взрывозащищенный водонепроницаемый ip65 Светодиодный прожектор для стадиона, спортивные стадионы, склад, ландшафт

Наружная игровая площадка высокой мощности 600 700 Вт 600 Вт Светодиодный прожектор для стадиона СВЕТОДИОДНЫЙ прожектор для спортивного стадиона теннисной площадки

Рекламные высокое качество многофункциональный Integra полюс фонарный столб

500W 750W 1000W 1250W 1500W LED Stadium Lights LED High Mast Light LED Flood Lights

Новые поступления

Новинки товаров от производителей по оптовым ценам