Китайский Ведущий бренд автоматическая двухцветная цилиндрическая трафаретная печатная машина использованные/Новые Чехлы для бутылок PLC банки шелкографии

- Категория: >>>

- Поставщик: Lc Printing Industries Company LimitedLc Limited

Сохранить в закладки 375322532:

Описание и отзывы

Характеристики

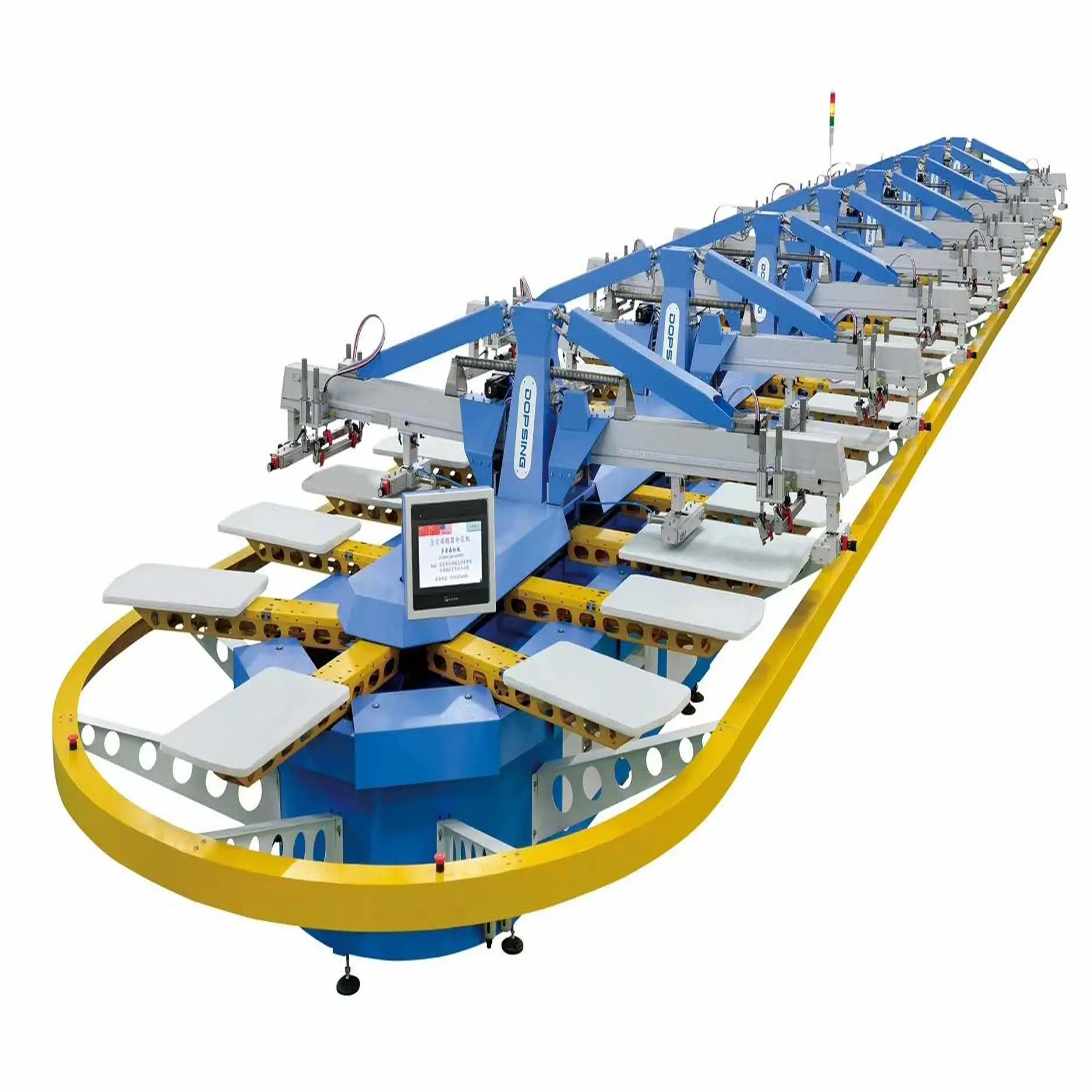

Plastic hollow containers are widely used in product packaging such as: medicine, cosmetics, detergents, lubricating oil, beverages, daily necessities, and chemical containers. They are generally made of PP, PE PET, PC and other materials by blow molding. More and more large-scale factories use automatic screen printing machines to print their products. Since this kind of screen printing machine is connected like a long queue, it is vividly called a silk screen printing dragon.

Screen printing dragon is the first automatic screen printing machine to enter the market, and it also occupies the largest share in the market. Now it is also the most standardized automatic screen printing machine. Its main structure is:

1) Feeding conveyor belt: It is a conveyor belt. The operator can place the product to be printed on the conveyor belt. The conveyor belt can automatically transfer the plastic bottle to the feeding position, and the feeding nozzle of the machine will suck the bottle To the transfer table of the screen printing machine. Some users will request to customize the automatic feeding chute, and the bottles can be put into the feeding chute, and the bottles will be automatically arranged into the feeding conveyor belt.

2) Pre-press device: The pre-press device includes orientation adjustment of plastic bottles and product surface treatment, such as flame treatment, plasma treatment, coating of PP oxidant, etc.

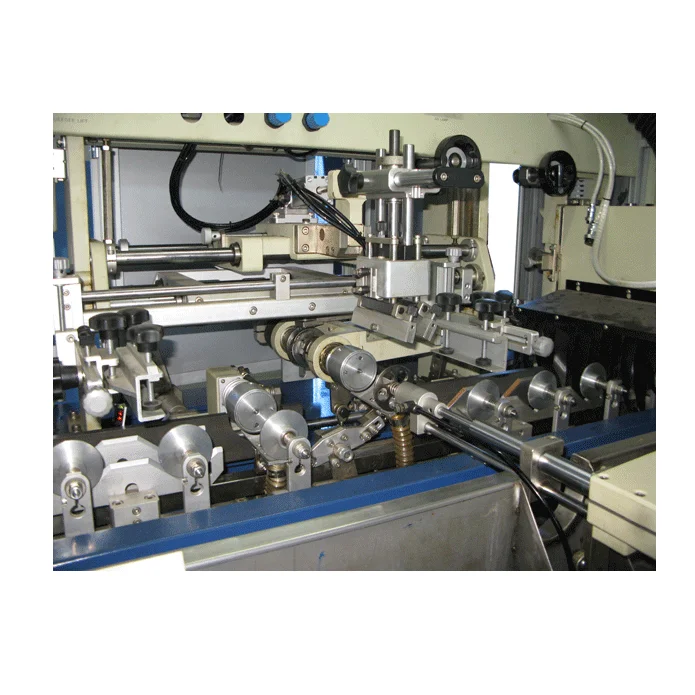

3) Printing system: The printing system of the automatic screen printing machine is similar to the printing device of the semi-automatic screen printing machine, but it has more functions. In order to improve the printing efficiency and precision, more and more movements of the screen printing device are controlled by servo motors, pneumatic components More and more international famous brands are used for electronic and electronic components, and the main parts of the machine are also processed with high-strength steel instead of aluminum profiles. The wear resistance and service life of steel materials are much better than aluminum profiles.

4) UV drying system and UVLED drying system: For continuous high-speed screen printing, an important option to ensure that the screen is not blocked is to use UV ink, which will basically not dry to the screen surface and affect printing unless it is irradiated by ultraviolet rays.

5) Unloading system: If you do not arrange the printed products, you only need one unloading conveyor belt, but if you need to arrange the printed products, the machine will be equipped with a manipulator and placed regularly on the conveyor belt.

Now more and more users choose automatic multi-color container screen printing machine, which actually integrates three processes of flame treatment, silk screen printing and curing, which not only greatly reduces the labor intensity of the operator, but also greatly improves the printing quality of the product. Factories that are accustomed to semi-automatic screen printing machines have also begun to upgrade and purchase brand new screen printing machines to expand production capacity.

S-B120UV2 Automatically screen printing machine//Usage and characters | |

Guide |

|

Application fields |

|

S-B120UV2 Full automatically screen printing Machine//Parameter | |

Technical parameters |

|

Works supply |

|

Package list |

|

H.S.Code | 8443198000 |

Certificate | CE |

S-B120UV2 Two colors full automatically screen printing machine//Advantage | |

Function |

|

Main configuration |

|

Catalogue

Machine details

1. What is a screen printer?

Screen printing machine uses rubber squeegee to apply pressure on the ink on the screen plate. the pattern is transferred onto the product through the hollow area. It is the most widely used special printing equipment in the industrial field. It is also the most compatible printing equipment for products materials.

The UV screen printing process is also a relatively common silk printing process. When using UV inks instead of ordinary dry inks, you need to choose a UV curing machine or LEDUV curing machine to achieve this process.

2 . The difference between the Vacuum table screen printer and T -shaped screen printer

The products involved in the plane screen printer are generally divided into two types. One is relatively thin and thinner products, such as paper, film, and general workbenches that need to be inhaled. They will be adsorbed when printing , for a product with a certain shape and quality. You can choose a T -shaped screen printer, which usually makes a fixture to fix. Automatic silk printing opportunities connect to automatic feed mechanisms and unloading mechanisms to achieve the automation of screen printing.

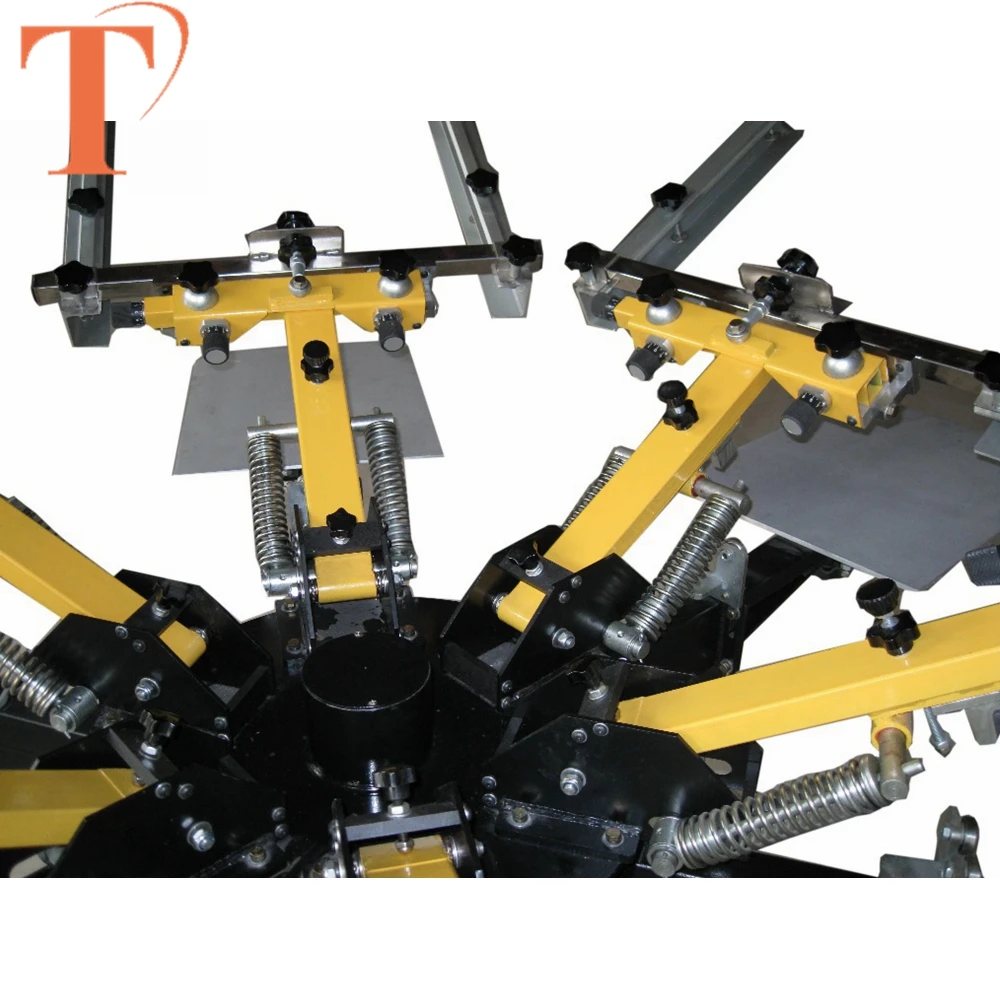

3. Shuttle screen printer and Turntable screen printer

The limitations of the single workplace screen printer are very obvious, it is necessary to wait for one product to complete the screen printing before the other product can be placed. The production efficiency is affected. Like the pad printer, the screen printer can also install the shuttle workbench and the turntable workbench. There are two structures, front and rear movements and left and right movement, which are generally large -sized; turntable screen printers are relatively popular screen printers. During the silk seal period, stations continued to rotate, saving working time, and improved production efficiency. The turntable screen printer is generally suitable for products with smaller size.

4. Screen printing machine operating system

The ordinary screen printing machine adopts the microcomputer control system to carry on the control, the high-end screen printing machine uses the PLC to carry on the control, specially the servo control system screen printing machine or the automatic screen printing machine, uses the PLC control system quite commonly because it need more parameter setting during screen printing.

5. How to evaluate the quality of the screen printer

Screen Printing machine technology content is low, more and more enterprises began to produce and sell screen printing machines, screen printing machines of uneven quality, how to evaluate the quality of screen printing machine is essential. As the majority of brand-name screen printing machine is not sold through the network, so, through Alibaba sales of screen printing machines are not high end screen printing machine.

1) Design of the factory means: a special design department of the enterprise quality is more reliable. China has 70% of the screen printing machine manufacturing enterprises and no special design department, the development of new products on-site assembly by the basic, which is extremely adverse to the standardization of production machinery;

2) Processing means: CNC processing costs are higher, but the parts manufactured high precision; visit the factory must inspect whether the factory has CNC machining capacity;

3) Materials Selection: Material selection is very important. Now fierce competition, the vast majority of domestic factories in the selection of the above efforts, only the brand enterprises are willing to insist on the selection criteria above;

6. What is screen plate of screen printer?

- Printing machinery industry Alibaba 15 years golden supplier .

- 18 years of sales experience. areal understanding of customer need.

- Clearly marked price, earn consciencemoney. Profits no more than 20%.

The world is only one China, China only one LC, we are the production and sale of pad printing machines, silk screen machines, bronzing machines and automatic printing equipment and world famous!

Excellence in product quality depends on the high precision machining equipment;

The company has dozens of leading domestic CNC, printing machines, silk screen machines, bronzing machines and other special printing equipment, data and standardized management in the forefront of the domestic.Excellence in product quality depends on the high precision machining equipment.

Pad printers:

- 1 color, 2 colors, 4 colors, 6 colors, 8 colors, 10 colors

- Closed cup pad printer and open inkwell pad printer;

- Customize full automatical pad printer;

Screen printer:

- Plain screen printing machine and Multi-function screen printing machine

- Pneumatical screen printing machine, Motor screen printing machine

- Full automatical screen printing machine

Hot foil stamping machine

- Manual, Sem-auto plain hot stamping machine and Cylinder hot stamping machine

- Hydraulic hot foil stamping machine;

- Full automatical hot foil stamping machine

All Machine has CE certification.

CE of pad printers

CE of screen printers

CE of hot foil stamping machine

CE of UV exposure machine and UV curing machine. Etc

1) What are your main products?

Pad printers,

Silk screen printers,

Hot stamping machines,

and the supply chain related to the above-mentioned industrial printing, we will also provide users with complete printing solutions.

2) What kind of pre-sale service do you provide.

Free technical consultation, pictures, technical materials, and video materials are provided. For those that cannot be provided, we may provide design solutions.

3) What kind of payment method should I choose?

For new users, if the amount is smaller, you can use the credit guarantee order, TT, and if the amount is larger, you can consider a letter of credit. In order to protect the safety of customers' funds, we do not recommend customers to transfer to personal accounts, or use Western Union, paypal and other personal payment methods. Unless the customer makes a special request.

4) How to order the machine?

When you confirm to buy the machine, we will provide PI, and pay according to the payment method guided by PI. We will produce the machine and arrange the calculation until you get the machine safely.

5) Questions about proofing?

For direct users, it is very important to confirm whether the machine is suitable for their products and require the factory to carry out proofing as the standard for machine delivery, because pad printing machines, screen printing machines and hot stamping machines usually require fixtures, printing plates, and inks. The perfect match of the bronzing paper can meet the requirements. For the proofing of the customer's confirmed order, we are free. For the proofing without the confirmed order, we will charge a certain proofing fee. When you confirm the order, the proofing fee will be deducted from the machine purchase price.

6) How about after-sales service?

Companies that sell through the Internet are usually small in scale, and none of them have set up after-sales service points overseas. After-sales service requires online support from sales staff. In general, pad printers, screen printers and hot stamping machines are relatively simple machines, and most problems can be solved through online communication.

7) How do you evaluate the quality of your products?

When each user purchases a product, he balances price and quality. This balance may be difficult to grasp, but this is how you do business. Most of the products sold on the Internet are in the middle of whether the price is not low or the quality is not bad. end. You have to negotiate professionally with the sales staff for better products. There are roughly 300 similar manufacturing plants and more than 8,000 trading companies in China. It is not difficult to choose products that suit you.

Похожие товары

SM8-4050E 8 станций ротационный принтер для печати на футболках цветов с ручным управлением многоцветный этикеток

Автоматическая роликовая промышленная трафаретная машина с высокой точностью

Высококачественная рубашка на заказ футболка с принтом пустая овальная трафаретная печатная машина автоматическая

Лидер продаж Поворотный 6 цветов футболка карусель трафаретная печатная машина sablon impressora

Горизонтальный подъем полуавтоматическая Термотрансферная бумага вакуумная сериграфия/сериграфия трафаретная печатная машина

Дешевая 4 цвета станции вращающаяся шелкографическая машина ручной шелкографический принтер для продажи

Фабричная высокоскоростная 2-цветная полностью автоматическая машина для трафаретной печати стекла с конвейерной лентой подачи и разгрузки бутылки вина

Новые поступления

Новинки товаров от производителей по оптовым ценам