Пластиковые литья под давлением пластиковые

- Категория: Электронные пластиковые >>>

- Поставщик: ALBANY TECHNOLOGY CO. LTD.

Сохранить в закладки 464741237:

Описание и отзывы

Характеристики

Our company is a factory engaged in aluminum die casting and precise CNC machining with thirty years' experience in Taiwan area. Our business is based on OEM and our customers are mainly from North America, Europe and Japan in different fields, such as medical, solar energy, communication and heavy industries.

We offer services of aluminum die casting, precise CNC machining and secondary operation, such as anodizing, powder coating, plastic injection molding, powder metal processing, investment casting, zinc casting, sand casting and whole product assembly service.

All different file formats of 3D or 2D drawings are acceptable. Mold design and building have been our strengths in the past three decades.

You'll find us your worthy and reliable long-term business partner.

30 year experience

strong computer technical support

OEM & ODM by customers

ISO9001: 2015

manual plastic injection / plastic injection robot

- over thirty years in plastic injection molding parts and mold building

- different materials are available: ABS, nylon, nylon with glass fiber, polycarbonate POM, PP, PS, flame retardant, high impact.

- strong computer ability. We accept different kind of computer file formats in 2D or 3D drawings

- quickly mold building lead time.

- hand-made prototype are available.

- export molds making

- final products assembly

Plastic injection product

Plastic Injection Product for electronic plastic part

running ahead to be competitive. being honest to earn long-time business.

Mold base | LKM,FUTA,HASCO,DME, etc. |

Cavity Number | Single or multiple LKM, FUTA, HASCO, DME, etc. |

Mold Material | S136,S136H,SKD61,NAK80,SKD61,SKD11,SKH51,NAK55 VIKING,635,DC53,P20,2316 etc |

Shot runner | Cold or hot |

Design and program software | CAD/CAM/CAE, UG, PRO/E |

Machines | CNC,EDM,advanced plastic injection machines |

Mold Life | 1000K~2000K Shots available |

Lead Time | 20-30 days |

Mould making steps :

1.Negotiation | Quality,material,price,payment,deliverytime,etc. |

2.Order | According customers’ drawing or sample |

3.R&D | According customer’s required design or improve 3D drawing. |

4.Design confirmation | We send 3D drawing to customer to confirm before we make the mould. |

The character of mould design

1) Mould design is a brain demanding work which has no copy action.

2) When designing a mould the method of modification should be taken into consideration and should leave enough space for modification.

3) The devices of the mould should meet the standard of anti-grating and long-life shots.

4) The manufacturing skill and time is different with the hardness and stretchiness of the material.

5) Making a mould takes a long period of time.

6) Because of its precision, most of work has to be done by manual work.

7) Mould of high quality should be qualified with good surface manufacturing and precision

Похожие товары

Home & Factory использование клей-обратно крепление автомобиля кабельные зажимы провода 5 мм FC-03

Новый продукт, высококачественный цветной корпус из АБС-пластика под заказ для электронного пластика

Китайский стоящих перед польской дирекцией мембрана N-W серии для электролиза воды для того чтобы произвести водорода

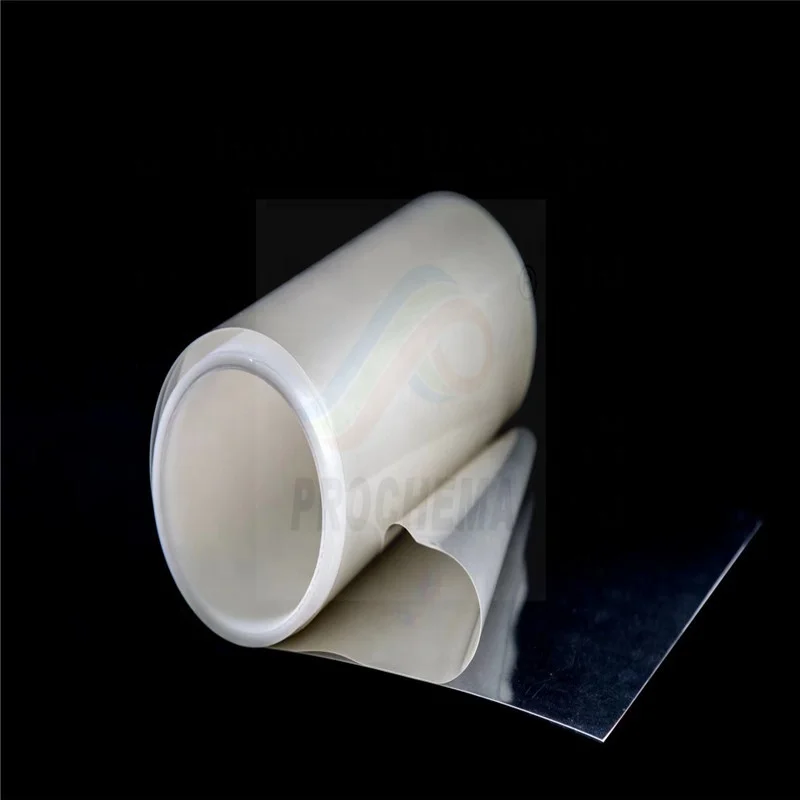

Электрическая изоляционная пленка ETFE, полупроводниковая изоляционная мембрана ETFE

Лидер продаж, держатель для светодиодной ленты из черного нейлона

Нейлоновый крепежный зажим

Taichen, Китай, нейлоновая пластиковая Проставка для печатных плат

Новые поступления

Новинки товаров от производителей по оптовым ценам