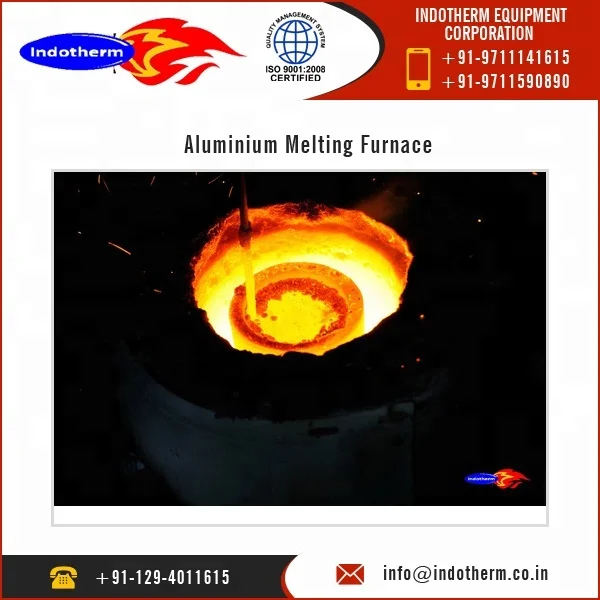

Фиксированная алюминиевая плавильная печь для литья под давлением грузоподъемность материала (Т): от 100 кг до 1000

- Категория: >>>

- Поставщик: INDOTHERM EQUIPMENT CORPORATION

Сохранить в закладки 50032929843:

Описание и отзывы

Характеристики

We are highly appreciated in the international market for our exquisite collection of Aluminium Melting Furnace. The furnace we offer is considered for holding and preserve of molten metal. It is suitable for transport between molten aluminum to the workstation. This type of furnace is used in pressure die and gravity die casting foundry. These furnaces are used to hold and maintain the molten metal at specific temperature inside the crucible.

Indotherm Equipment Corporation manufactures High Grade insulation furnace with optimized connected loads used for both Melting and Holding Operation. Our Furnace feature good melting output together with outstanding temperature uniform in melt.

Our Manufactured Resistance furnace can attain temperatures ranging from 1100 °C up to 1300°C to melt Aluminum, Brass as well Bronze.

Multilayer Insulation of High Grade Ceramic Fiber to withstand temperature up to 1600 °C. The furnace chamber insulation with high-quality lightweight refractory bricks is recommended for holding operation for rapid heat-up times in non-continuous operation.

Our manufactured Resistance furnace for melting non ferrous metals comes with High Temperature heating elements a rigid construction of 8 mm thick shell and Silicon Carbide Crucible furnace along with control panel with an Automatic Temperature Set control system.

Uniform heating using heating elements, Simple replacement of individual heating elements. In case of crucible breakage, only the defective heating elements on each level need to be replaced.

Our Furnace comes with a unique technology where it can be operated in reduced power in case of any trouble in the inside portion of the thermocouple, in order to prevent the freezing of the material.

Over-temperature limiter in furnace chamber for protection against overheating. The limiter switches the heating off when the set limit temperature is reached, and only switches it back on after the temperature has fallen again

Ranges available for 100 Kgs to 1000 Kgs per Batch.

Features:

- Compact design

- Less maintenance

In the year 1995, Indotherm Equipment Corporation started its operation with a vision of manufacturing, exporting, and supplying of high standard Furnace and Belt Conveyor. Being an ISO 9001:2008 certified firm the range of products which we have been delivering to our comprise Hydraulic Tilting Furnace, Reverberatory Furnace and Tilting Reverberatory Furnace. We started our operation with an aim to deliver a product which is safe and environment friendly as well. Our range of products saves energy and consumes less fuel which is one of the major features of our product.

We have a directory of authorized vendors and after having an aggressive research, we select the most reliable vendor. The raw materials which are supplied to us are quality checked at their end, we after acquiring it from them also conducts a quality test and thus make sure that it meets the industry parameters. Since we started, we have been highly appraised by the clients for delivering them an excellent product. In these years of operation, we have been able to create a position in the market by offering excellent quality of service and products. We also have an excellent packaging unit equipped with latest machinery which helps in packing the products, making sure that they are safe while being exported and supplied. We also have an efficient team who keep themselves up breast with the technology and accordingly put their efforts in delivering high-class products. We export our products across the globe.

Our Team

Our firm is organized by expert professionals who have adequate knowledge about the industry and understands their job properly. We also have a team of engineers who are efficient enough in bringing out a qualitative product. Our team is well versed and knows the standard, which they meet during the production, packaging and supplying of these products. They are also familiar which the machineries we use in the manufacturing unit.

Our Products Range

Industrial Oven Manufacturers, Combustion Equipments Manufacturers, Roller Hearth Furnaces, Pusher Type, Gas Carburising Furnaces Accessories, Furnace Manufacturer in Delhi NCR - Furnace, Refractory’s , Furnace Manufacturer furnace manufacturer in Delhi NCR - Get free price quotations, products, Furnace Manufacturer, Furnace, Refractories & Industrial Ovens, Furnace Heat products.

Why Us?

We bring our customers a safe and secure product which with its durability continues to give a competent performance. Our whole range of products is purely safe for the environment and is developed as per the industry norms. Quality wise they are high and are very economically priced. We are backed by an efficient team and well equipped infrastructure which also makes us capable to deliver bulk orders in the given time-frame.

Our Excellence

Our knowledge has been functioning for over 20 years with flourishing in the universal Aluminium industry, where we are well thought-out as a spot supplier for the chief and derivative industries as well as for the aluminum foundry industry. Our ground-breaking modern colossal equipments and plan solutions that protect profitability merit goes to better energy efficiency, reduced upholding downtime, and longer repair cycles.

Our worldwide presence and local experience allows us to offer the most suitable and cost effective technical solutions that will contribute to our customers' productivity and efficiency. In the aluminium industry, we focus our efforts on the following concerns:

- Ensure the safety, reliability, and productivity of the equipment

- Suppress corundum build-up

- Withstand mechanical abuse

- PRODUCTS & APPLICATIONS

- INSTALLATION, COMMISSIONING AND TURNKEY MAINTENANCE

- TURNKEY NEW PROJECTS

Infrastructure Facilities

We have a huge infrastructure which is segregated into different sections and is equipped with the latest and innovative technology. All our sections are run under a strict supervision of our supervisors who in every level pays adequate attention. We also have a record room, where we maintain records of the products being exported and supplied along with time and date to the client and a store room too.

| Copyright © 2017. indotherm Equipment Corporation. All Rights Reserved | Product Ranking Service by Opal Infotech |

|---|

Похожие товары

Лидер продаж, коробка для нижнего белья, бумажные коробки для нижнего белья, коробки для упаковки яиц, картонный поднос по низкой цене

OPT SHR машина для удаления волос IPL лазер e-свет Горячая продажа лазерная машина

Подходит для Mercedes Benz V-Class Vito tachograph speed sensor A0125423117

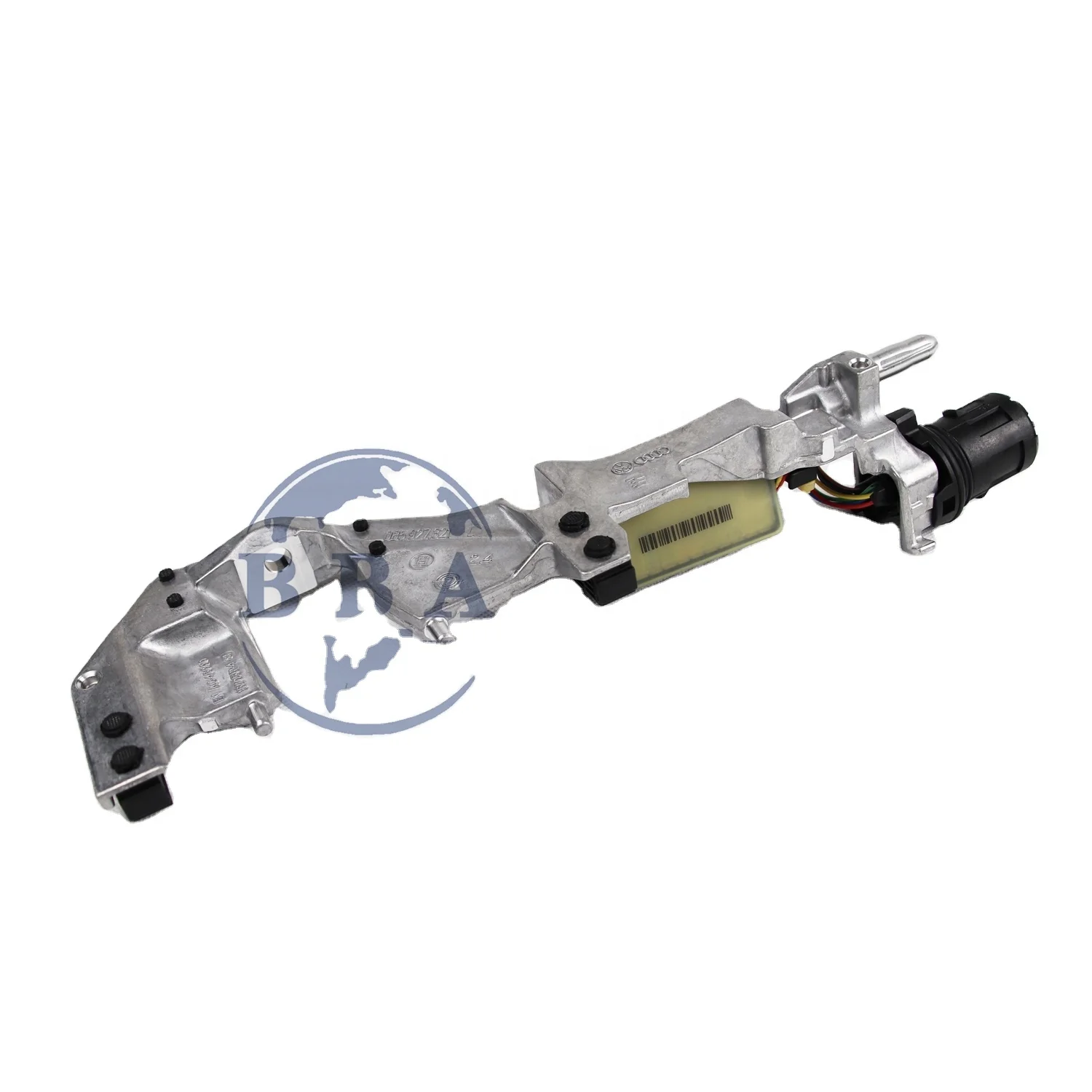

Новый 0B5 DL501 автоматический модуль датчика коробки передач L S/S к L для A4 A5 A6 A7 Q автоматическая коробка передач OB5 927 321F OB5 переключатель

ЧПУ резак нож резьба резка длинные биты кобальтовый станок сверла фреза твердосплавная древесина гравировальная

Датчик температуры автозапчастей для MERCEDES-BENZ 2022400518

Датчик износа тормозной колодки для Mercedes Benz V-Class Vito A6385400736

Новые поступления

Новинки товаров от производителей по оптовым ценам