Горячая Распродажа 28 мм 38 красочные PE пластиковая крышка для пэт бутылка от производителя

- Категория: Пробки на винные бутылки >>>

- Поставщик: Zhangjiagang King Machine Co. Ltd.

Сохранить в закладки 60092532762:

Описание и отзывы

Характеристики

Our PET materials Features:

1) BPA FREE

2) DEHP (plasticizer) Free

3) Better Izod impact strength than PC

4)ECO-Friendly Materials

Our PET Preform Features:

1) 100% new material

2) High transparency

3) High toughness

4)Blowing Rate up to 99.8%

5)Low Defect Rate

6)Low cost

7) a wide range of neck and weight perform

8)Different colors is workable,like black,Tsmoke,Taqua,Green,Red,Purple,Royal,yellow,White etc.

9)Open new molds with low cost and less time

Neck and application:

•\tPCO 28mm PCO 1810 And 1881 for CSD and mineral water

•\tPCO 28mm PCO 1810crystallized for hot fill 95 ℃

•\tEuropean neck finish 30/25,29/21 for water

•\t38mm 3-start,2-start for milk and juice plus specially finished preforms for hot fill

•\t29/21mm , 36mm 46 65mm snap-on neck finish for edible oil

•\t45mm,46mm for big bottle

•\t15/410,18/410,20/410,24/410,24/415,28/410,32/410,38/400 neck finishes for cosmetic bottle, detergent bottle

•\tPreforms for wide-mouth jars

•\tPreforms for the production of 1gallon,2gallon,3 gallon,5 gallon/ 19 liter PET bottles for water, oil and agricultural products

King Machine Blow Molding Machine.

1 / King Machine Blower : Industry-leading blower performance with patented control and self-regulation systems for repeatable and consistently high bottle quality

2 / Production flexibility: Up to 200 different equipment size configurations from one platform

3 / Top quality: Electrical stretching for bottle integrity, full material distribution control and performance

4 / Fast output: Boosted uptime and speed (up to 2,400 bottles/mould/hour)

5 / Efficient consumption: Up to 45 % less electricity and 35 % less compressed air

Want to know more message , contact us with out hesitate ! Inquiry us now !

What King Machine can do for you ?

Bottle Design

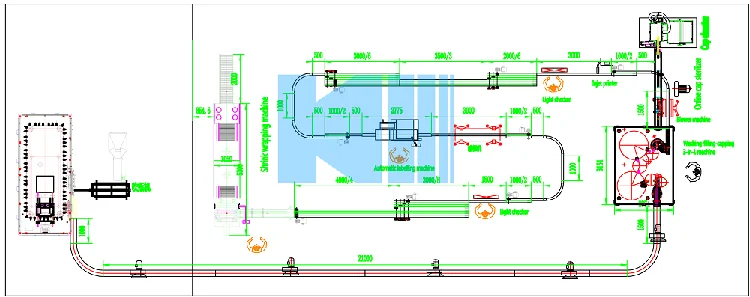

Whole Line Layout

Your Factory Workshop Building

Sample Project All Around the World

Want to know more message , contact us with out hesitate ! Inquiry us now !

Zhangjiagang King Machine Co.,Ltd

1 / Standardized workshop of total 20,000 square meters.

2 / The equipment will be tested and run for 24 hours before leaving the factory, to ensure the smooth working of water pipeline, and pneumatic, electrical and mechnical stability.

3 / Sufficient stock of spare parts ensures the timely delivery and supply of spare parts.

King Machine Sales Manager Team and Engineer Team.

1 / Professional installation team who can speak fluent English can help customers make benefits in a shortest time.

2 / The engineers are experienced. We can produce different products with different capacity and work out reasonable flow chart as per customers' requirements to save space.

King Machine Cetificates and Patents.

International certification, National Certificate of equipment verification, and more than 30 invention patents are done in King machine .

Verification Certificates of equipments: ISO9001:2001; CE Certificate , SGS , COC , TUV

National Certificate of equipment verification:standard organisation of Nigeria , CNCA certificate, Logo trademark registration, etc.

HOW TO FIND KING MACHINE?

● Search Alibaba, Made in China, Google, Youtube and find suppliers and manufactrue and not traders

● Visit exhibition in different countries

● Send King Machine an request and tell your basic inquiry

● King Machine sales manager will reply you in short time and add instant chatting tool

YOU ARE WELCOME TO OUR FACTORY AT ANY TIME.

● If we can fullfill your request and you interested in our products, you may pay a visit to King Machine site

● The meaning of visiting supplier, because seeing is believing, King Machine with own manufacture and developed& research team, we can send you engineers and make sure your after sales service.

HOW TO GUARANTEE YOUR FUNDS TO BE SAFE AND DELIVERY TO BE ON TIME?

● Through Alibaba letter guarantee service, it will ensure the on time delivery and the quality of the equipment you want to buy.

● By letter of credit, you can lock the delivery time easily.

● After the factory visit, You can ensure the facticity of our bank account.

SEE KING MACHINE HOW TO ENSURE THE QUALITY!

● In order to ensure the accuracy of each part, we are equipped with a variety of professional processing equipment and we have accumulated professional processing methods over the past years.

● Each component before assembly needs strictly control by inspecting personnel.

● Each assembly is in charged by a master who has working experience for more than 5 years

●After all the equipment are completed, we will connect all the machines and run the full production line for at least 12 hours to ensure the stable running in customers' factory

THE AFTER-SALE SERVICE OF KING MACHINE!

● After finish the production, we will debug the production line, take photos, videos and send them to customers via mail or instant tools

● After the commissioning, we will package the equipment by standard export package for shipment.

● According to the customer's request, we can arrange our engineers to customers' factory to do the installation and training.

● Engineers, sales managers and after-sales service manager will form a after-sales team, online and off line, to follow the customers' project.

Похожие товары

18/410 18/415 20/410 24/410 28/410 винтовая крышка для пластиковых дозирующих бутылок PP flip top cap для бутылки для шампуня

Самоклеящаяся крышка бутылки с чувствительностью к давлению, алюминиевая уплотнительная прокладка, прокладка, крышка, пенополиэтиленовая крышка, герметичная крышка для вашей защиты

18/410 г. длинная пластиковая Распылительная насадка медицинский винтовой насос опрыскиватель ротовой распылитель для

Creherit водонепроницаемые дышащие пенопластовые вентиляционные вады с отверстиями

Термоусадочная крышка из ПВХ пробковая Крышка для винных

Индукционная герметизация 28 мм пластиковая ламинированная алюминиевая фольга уплотнительные крышки для PP PET PVC PS ABS стеклянных

Оптовая продажа, под заказ, деревянная крышка, t-образная, стеклянная бутылка для вина, синтетическая пробка, пробка для бутылки вина

Новые поступления

Новинки товаров от производителей по оптовым ценам