Pdc буровые долота для нефтяных скважин цены/алмазное буровое долото

- Категория: >>>

- Поставщик: Hejian Huanyu Petroleum Machinery Co. Ltd.

Сохранить в закладки 60122230385:

Описание и отзывы

Характеристики

Matrix PDC Drill Bit Water Well Drilling Or Oil Well

| PDC Bit Specification | |||||||

| Size | IADC | Blades | Nozzles | Cutter Size | API PIN | WOB | RPM |

| 6 1/2'' | M332 | 5 | 5 | 13mm | 3 1/2'' | 10~110KN | 60~220 |

| 8 1/2'' | M323 | 5 | 5 | 16mm | 4 1/2'' | 10~110KN | 60~220 |

| 9 1/2'' | M323 | 5 | 5 | 16mm | 4 1/2'' | 10~110KN | 60~220 |

| 12 1/4'' | M323 | 6 | 5 | 19mm | 6 5/8'' | 10~110KN | 60~220 |

Production cycle: 5-30 days(PDC), 10-60 days(roller cone bit)

Major market: North America,Middle east area,Africa,Europe

Package: Iron or Wooden box Annual output: 10000 pcs

1. Are you trading company or manufacturer ?

We are a professional PDC bit and roller cone bit manufacturer.

2. Whether accept customized according to customers' requirements ?

Yes, We accept customized, no matter what size and type ,and MOQ is 1 piece .

3. About lead time and shipping time?

The lead time depend on quantity of order. Usually it will takes 3-5days shipping to Tianjin Port or Beijing Airport,China .Even the small order or urgent order we can send you by air after received your agreement. According the distance from china to your port, usually from China to European about 25-30 days. To West of American 20-25 days.

4. It is produced according to the standard?

Yes. All our activities are accredited to ISO 9001:2008 and API, both in products and services, at the same time, mature production technology ensuring the quality satisfy international request,we had strictly inspection in the production. Exported to the Middle East, Europe, North America, South America, Australia and other countries and regions.

5. Can I expect a quality product?

Yes. All our activities are accredited to ISO 9001:2008 and API, both in products and services, at the same time, mature production technology ensuring the quality satisfy international request.

6. How do you guarantee your quality?

We select the advanced production technology and equipment, strictly control the whole production process,and we inspected the finished drill bits,we can also make several design changes according to the customer's feedback, and finally ensure the customer's excellent drilling effect.

PDC Bits For Well Drilling

Feature:Improved support and retention.

Advantage:Manage the magnitude cutter loading and bit torque.

Benefit:Improved bit duoability and directional responsiveness.

Advantage:Higher nozzle counts and/or fixed ports to best serve cleaning cooling and cuttings evacuation requirements with available hydraulic flows.

Benefit:Optimized ROP and bit life. Longer drilling intervals without need for tripping.

PDC Oil Drilling Bits

- Optimized short parabolic profile, suitable for drilling soft to medium soft homogeneous formations

- Asymmetrical evolute spiral blade cutter placement makes the bit more stable during drilling

- Primary and secondary cutting structure extends bit life

- CFD hydraulic balance design results in better bit cleaning and cutting removal

- Combined utilization of high performance PDC compacts significantly prolongs bit life

Bit size (in) | Specifications | Recommended drilling parameters | ||||||

No. of cutters (pcs) | Gage length (mm) | No. of nozzles (pcs) | API reg. pin size (in) | WOB (kN) | RPM (r/min) | Mud flow rate (l/s) | HHP (w/mm2) | |

8 1/2 | 26 | 85 | 4 | 4 1/2 | 30-100 | 50-250 | 25-35 | 2-7 |

12 1/4 | 41 | 120 | 6 | 6 5/8 | 50-160 | 50-250 | 44-60 | 2-7 |

Feature:Diamonds are impregnated in the matrix behind the PDC cutters.

Benefit:Increased footage drilled in abrasive applications.

Feature:Larger than standard TFA.

Packing Terms:wooden box, steel box or as your requirements.

Model | 118,152,215.9,244,311,445 |

Type | all kinds and size PDC bits |

Applicable | water well, oil field, construction, geothermal, directional boring, and underground foundation work |

Formation | sticky, soft, medium hard, hard formation |

Bearing | rubber seal or metal seal |

Packing | wooden box, steel box, or as your requirements |

Payment Term | T/T or L/C at sight |

MOQ | 1 Piece |

Supply Ability | 1000 Pieces/month |

Delivery Time | within 7-15 work days |

Application Of The PDC Bits

1,Suit for drilling medium to medium-hard formations.

2,Evolute asymmetrical blade cutter design and balanced bit load so that bit whirl is prevented .

3,Composite gage protection and low torque design improve rate of penetration .

4,CFD hydraulic balance design results in better bit cleaning and cutting removal .

5,Combined utilization of high performance PDC compacts significantly prolongs bit life

Bit Type | Main bit size(mm) | Rock Coefficient | |

PDC core drill bit | Single pipe | 75/54.5 94/74 113/89 113/109 153/129 | 1-18 |

Two pipes | 75/54.5 94/68 | 1-18 | |

PDC center drill bit | Concave 3 wing bit | 60. 75. 94. 113. 133. | |

Arc pillar | 60. 75. 94. 113. 133. | 4-18 | |

Many wing scraper | 60. 75. 94. 113. 133. 153. 173. 190. 215. | 1-6 | |

PDC Indexable drill bit | 153/94 153/113 190/153 190/113 | 1-18 | |

Model | 3''-26''(matrix body and steel body) |

Type | Diamond PDC bits and diamond core bit |

Appliable | Water well, oil field, construction, geothermal, directional boring, and underground foundation |

Formation | medium,medium-hard ,hard formation |

Packing | Iron box |

Payment | T/T, L/C |

MOQ | One piece |

Supply Ability | 500 pieces/mounth |

Delievery Time | Within 30 days |

1. How to order the products?

Answer:

Send the inquiry with detail item description or with Model number.

If there is no packing demand we take it as sea-way packing.

If possible please attach one reference picture to avoid any misunderstanding or any links from our website forwe get a better understanding.

2. About lead time and shipping time?

Answer :

The lead time depend on quantity of order. Usually shipped by sea, small order or urgent order we can send you by air after received your agreement.

According the distance from china to your port, usually from China to European about 25 days. To West of American 20 days.

3.Can I expect a quality products?

Answer :

Yes. All our activities are accredited to ISO 9001:2008 and API, both in products and services, at the same time, mature production technology ensuring the quality satisfy international request.

4.Plz add these informations in you inquiry

1,bits size

2,bits IADC CODE

3,layer information

4,bits quantity

Похожие товары

Китай, Заводская распродажа, долота для обработки металла, квадратное отверстие, роликовое ядро, сверло для добычи

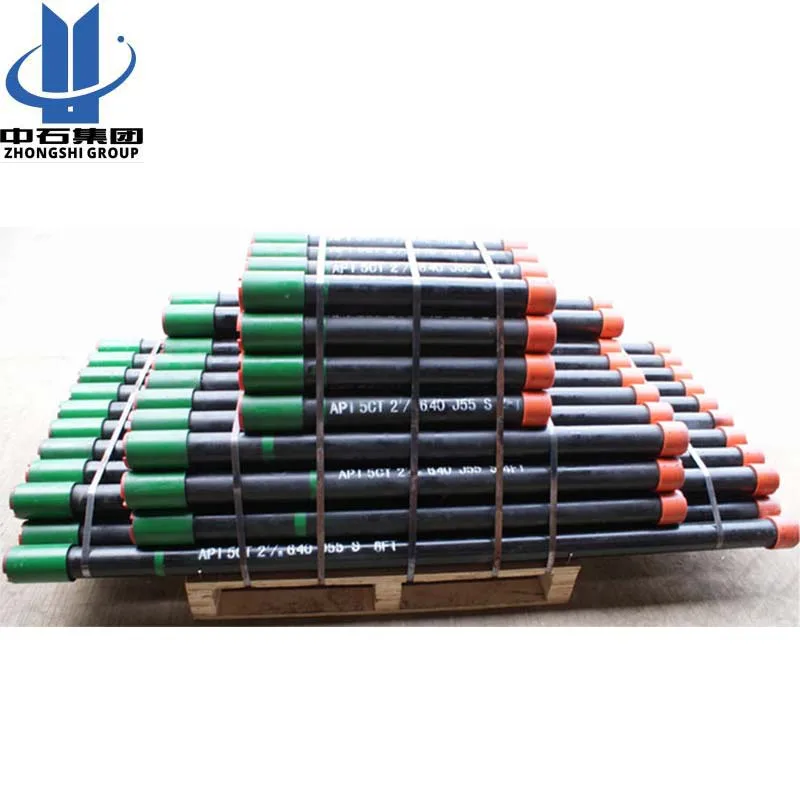

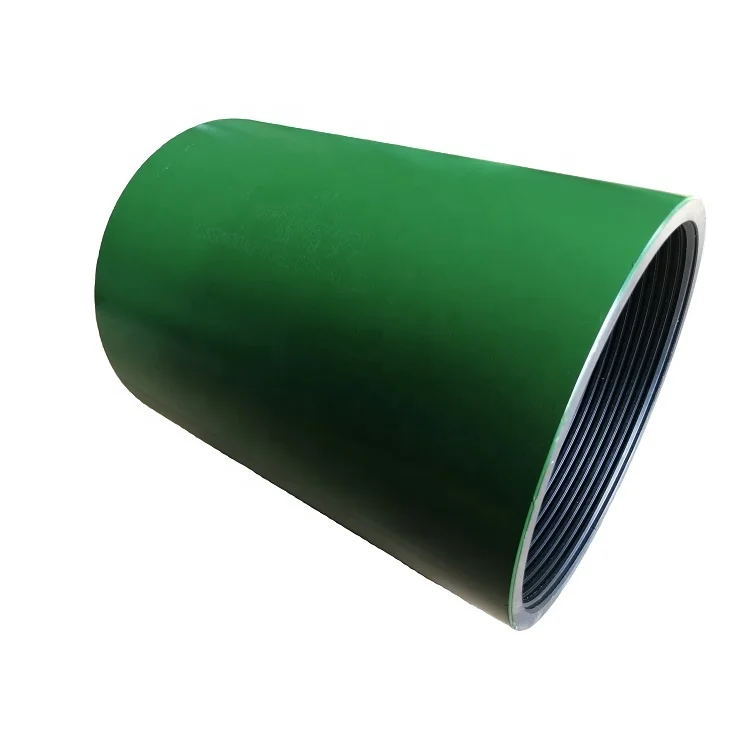

API 5CT корпус PUP соединение

Стальная труба API 5CT PSL-1 обсадная и Трубная муфта, используемая на месторождении нефти

API 5CT P110 9-5/8 'BTC R3 OCTG Корпус и трубка с муфтой

Дробилка для HT-7062252506

Ударная пластина для дробилки pf1315

Заводская цена, шлифовальные шарики для добычи энергии, цементные промышленные предприятия, новая и подержанная сталь и хром, кованая дробилка

Новые поступления

Новинки товаров от производителей по оптовым ценам