CN452S дощатый ящик пневматический инструмент Брэд обрамление блоковый пол катушечный пневмомолоток

- Категория: Nail Guns >>>

- Поставщик: Zhejiang Dongya Facility Co. Ltd.Zhejiang Ltd.

Сохранить в закладки 60139120619:

Описание и отзывы

Характеристики

CN452S Wooden Case Pneumatic Air Tool Brad Framing Block Flooring Coil Nailer

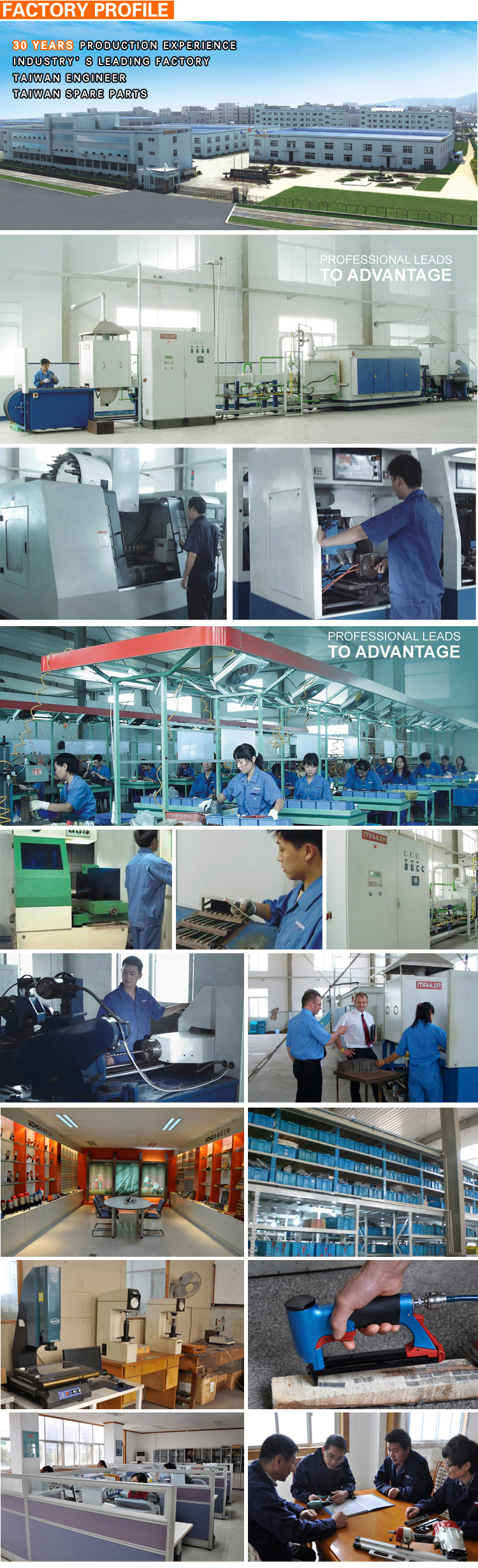

40 Years Production Experience

Industry's Leading Factory

Engineer With 30 Years Experiences In Nail Gun Industry

Imported Spare Parts

SPECIFICATION

FEATURE • 360° exhaust direction • "Contact mode" safety system • "Sequential mode" can be available by changing trigger • Light die cast body of aluminum alloy • Use 15°wire or plastic collated coil nails • Depth control system • Side loading system • Easy length adjust design |

|

Parameters

| Tool Diamensions: | 248x108x260mm (9.76x4.25x10.24 in.) |

| Net Tool Weight: | 1.60kgs (3.50 lbs) |

| Operate Pressure: | 5~7Kg/cm (75~100Psi) |

| Load Capacity: | 400 Nails Wire Collated Coil Nails |

| 200 Nails Plastic Collated Coil Nails | |

| Coil Nail Angle: | 15 Degree |

| Coil Nail Diamensions: | 1.59-2.1mm(0.138-0.197") |

| Coil Nail Cap Diamensions: | 3.5-5.0 mm(0.138-0.197 ") |

| Coil Nail Spacing: | 6.0-6.8 mm (0.236-0.268”) |

Advantage

1. 800000 working times

2. All spare parts are changeable with M A X

3. Easily broken parts are imported

4. 100% Spare parts can be supplied to you.

5. Very powerful for hard wood

6. Both wire collated coil nail & plastic strip nails can be used.

CN452S Wooden Case Pneumatic Air Tool Brad Framing Block Flooring Coil Nailer

MAIN APPLICATION FOR Pneumatic Air Tool CN452S

SERVICE AND REPAIRS

| No. | Symptom | Problems | Solutions | |

| 1.1 | Air Leak | Air leak in the cylinder cap when tools don't work | 1.Loose head valve piston seal or o-rings . | Check and replace the head valve piston set |

| 2.Worn or damaged o-ring or cylinder cap gasket under cylinder cap | Check and replace o-ring or cylinder cap gasket under the cylinder cap | |||

| 1.2 | Air leak in Trigger area when tools don't work | 1.Damaged o-ring in trigger valve | Check and replace o-ring | |

| 2.Damaged o-ring in trigger valve stem | Check and replace o-ring | |||

| 3.Dirt in the trigger valve | Check and clean the trigger valve | |||

| 1.3 | Air leak in cylinder cap when tools are working | 1.Damaged head valve piston o-rings | Check and replace o-rings | |

| 2.Damaged seal under cylinder cap | Check and replace seal | |||

| 1.4 | Air leak in nose when tools are working | 1.Worn or damaged bumper | Check and replace bumper | |

| 2.Loose driver(piston unit) thread | Check and replace driver(piston unit) | |||

| 1.5 | Air leak in Trigger area when tools are working | 1.Worn or damaged trigger valve head | Check and replace trigger valve head | |

| 2.Damaged head valve piston o-rings | Check and replace head valve piston o-rings | |||

| 2 | Failed to get driver(piston unit) back to the correct position completely. | 1.The driver(piston unit) is not straight or the driver guide(nose) is wrong assembled. | Straighten the driver(piston unit) or verify driver guide(nose) and magazine | |

| 2.Worn or damaged nozzle | Check and replace nozzle | |||

| 3.The space between piston o-ring and cylinder is too tight. | Check if the cylinder is adequate lubrication or replace the o-ring on the piston. | |||

1) 40 Years Production Experience

2) 21 Years Alibaba Gold supplier with High Reputation

3) Alibaba Trade Assurance USD300,000

4) 100% QC Inspection before Shipment

5) We have experienced engineers

6) Competitive Price

7) Lifelong After-Sale Service

8) Advanced Machines

9) CE Certificate and ISO 9001:2015

10) OEM Available

11) Sample Available

Похожие товары

AEROPRO AFN64 Professional Air Finish Nailer Brad Finish Nailer Air Nail Gun Pneumatic Powered Hand Air Tools

Электрическая цепь с винтовым пистолетом 18 в 20 в 21 в автоматический беспроводной электрический цепной пистолет

Ручные инструменты VICRING, популярные товары, небольшой сверхмощный 3-сторонний штапельный пистолет 4-14 мм, домашний каркас для крыши, беспроводной гвоздь, простой в использовании

Силовой степлер GreatStar 6 в 1, электрический степлер для обивки, для проектов «сделай сам»

Пневматический степлер 1013J

Пневматический инструмент, Лидер продаж, пистолет для ногтей, фоторамка, задняя пластина, пневматический пистолет для ногтей DFC

Промышленный степлер для степлера

Новые поступления

Новинки товаров от производителей по оптовым ценам