Машина для производства древесных гранул серии KL200 7 5 кВт/машина гранулирования семян

- Категория: >>>

- Поставщик: Laizhou Chengda Machinery Co. Ltd.Laizhou Ltd.

Сохранить в закладки 60178707888:

Описание и отзывы

Характеристики

Christmas Sale!

KL200B Flat Die Pellet Mill Introduction

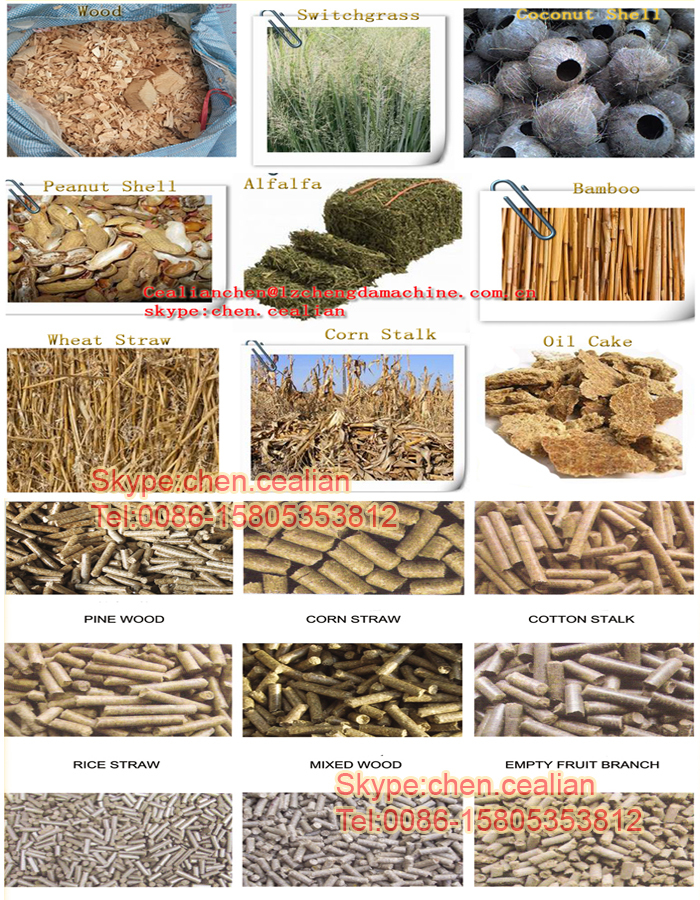

Electric flat die pellet mill is driven by electric motor which makes it more energy-saving and environmentally friendly. This electric flat die pellet mill is smaller in size, design and structure with capacity 150-190kg/h for making wood pellets, 300-400 kg/h for making feed pellets. Roller and flat die are made from precise material of alloy metal which makes this core part wear-resistant and not easy to break. With this pellet mill, if you want to make biomass pellets, you would better use relatively soft materials, as the machine design is stationary rollers and a running die mould. Ready-to-get raw agro waste materials are sawdust, wood chips, peanut shell, wheat straw, cotton, barley, branch, rice husk, sunflower stalk, palm kernel shell and many other materials.

Specifications:

1. This series machine can be powered by both diesel engine and e-motor.

2 .We adopt the new design of direct connection of motor shaft and he main shaft that overcome the loose defect of belt connecting as long time using.

3. High accuracy gearbox and high output.

4. It is widely used in large,middle, small scale aquatic. food and feed processing factory,

livestock farm, poultry farm, individual raisers, middle and small farm.

5. International advance steam fittings and imported pressure reduction valve.

6. Flat die is made with international advanced equipment for long lifespan.

7. Drive with heavy duty gearbox, which can produce continuously in most adverse condition.

Knowing your machine

Data of KL-B series pellet mill

| Model No. | Power(E-motor) 50HZ | Feed output | Wood output | N/G weight(kg) | Pellet diameter | Packing Size(cm) |

| KL120B | 2.2kw220v 1phase | 30-60 | 20-30 | 80/100 | 2.5-10mm | 75*32*62 |

| KL120B | 3kw 380v 3phase | 50-100 | 30-50 | 80/100 | 2.5-10mm | 75*32*62 |

| KL150B | 4kw 380v 3phase | 100-200 | 50-100 | 95/115 | 2.5-10mm | 77*34*68 |

| KL200B | 7.5kw 380v 3phase | 200-300 | 110-140 | 200/230 | 2.5-10mm | 100*43*95 |

| KL230B | 11kw 380v 3phase | 300-400 | 150-190 | 290/320 | 2.5-10mm | 114*47*97 |

| KL260B | 15kw 380v 3phase | 400-600 | 220-280 | 330/360 | 2.5-10mm | 120*52*107 |

| KL300B | 22kw 380v 3phase | 600-800 | 280-320 | 410/450 | 2.5-10mm | 127*52*107 |

The terms of warranty and spare parts

Our pellet mills are guaranteed with 1 year quality assurance from the date of goods shipment.

When we are talking about spare parts for a pellet mill, by and large, we are talking about die, roller and bearing. Practically, that how often you will need to renew spare parts is depending on what raw material you are making pellets from. Apparently, compared with making straw pellets, pellet mill that are making wood pellets requires a higher frequency for changing spare parts. We supply clients with high quality pellet mill dies, rollers, bearings and other parts. Clients are available to order at anytime. If you need spare parts, please contact me or test message.

Flat die Roller

How to Choose A Perfect Flat Die Pellet Machine

Flat die pellet mill takes the circular motion as the principle. The press roller, main shaft and die mould are of high quality alloy steel. There are common two design of flat die pellet machines: rotating rollers with stationary die or running die with stationary rollers. Though the two kinds of pellet mills can both make wood pellets and feed pellets, there is slightly difference. Roller driven pellet machine is more suitable for making biomass pellets, especially for making hardwood pellets; die driven pellet making has good performance in making feed pellets and soft wood pellets. Then, let us talk about the engine of pellet press. There are two choices, flat die pellet mill with electric motor and flat die pellet mill with diesel engine. Electric pellet mill is more energy-saving and environmental protection, while you must make sure there is enough electricity in your pellet making sites .

Working processing

Feed pellets for animals

Ready to exported

What can I do when my Pellet mill can not produce pellets?

A: New flat die pellet mill in first use may not produce pellets, because of the low smoothness of mould and bad cooperation in new devices. After using oily material for a period, the pellet machine can run smoothly.

B: The clearance between rollers and dies is too large. You can tighten the screw to narrow the gap to 1.5-2.5 mm.

C: Necessary steps to update a new die or roller shell because of wear and tear caused by long-term service.

D: The material is too wet or too dry, resulting in low productivity. You’d better increase or decrease the moisture to proper rate, generally 14%-16% in raw material.

Kinds of row materials and working processing

Homemade Pellets Used as Stove Fuel

Home pellet stove is widely used in Europe and many other places in the world. It is an environment-friendly method to keep warm and cook. Pellet stove uses less natural resources as its fuel is generated from waste or recycled materials. The fuel it used can be made at home. Here are a few tips for you to spend less money making the stove fuel if you choose a pellet stove for heating.

Home pellet stove is widely used in Europe and many other places in the world. It is an environment-friendly method to keep warm and cook. Pellet stove uses less natural resources as its fuel is generated from waste or recycled materials. The fuel it used can be made at home. Here are a few tips for you to spend less money making the stove fuel if you choose a pellet stove for heating.

You have to prepare raw materials along with a flat die pellet mill which is used to press the materials into the needed fuel for home. There are a wide variety of raw materials that you can use to make the fuel, such as fruit pits, different types of grass, corn cobs, barley star, shelled corn, wheat, paper, etc. Your choice of materials decides the heating or cooking effect, thus you need to look up the kind of stove to properly match the pellet fuel.

Our factory and certification

As 7/24 email and phone call service is available, I am ready to answer your any specific questions regarding to our machinery and pellet mill in particular. In addition, we prepare the teaching videos in terms of installation, lubrication, trial running, parts replacements and so forth.

Packing and shipping

Contact information

Welcome to my company!

Похожие товары

200 кг/ч плавающий корм для рыб машина производства кормов собак экструдер домашних животных

Заводская обычно используемая сервисная пила машина для производства пылевых гранул кормов крупного рогатого скота

Мельница для пищевых продуктов SunPring hummer с сетчатым кормом 0009r и пищевой хуммерный станок молотковая мельница Смешанная домашняя птица

Furui кукурузная дробилка аксессуары

Вертикальная молотковая мельница

Маленькие китайские кофейные зерна куриные кормы сахар в порошке арахис кукуруза пшеница сорго мука мельница шлифовальная машина специи

Заводские обычно используемые машины для обработки кормов домашних животных срок службы шлифования

Новые поступления

Новинки товаров от производителей по оптовым ценам