Машина для производства резиновых тапочек/пресс сандалий

- Категория: >>>

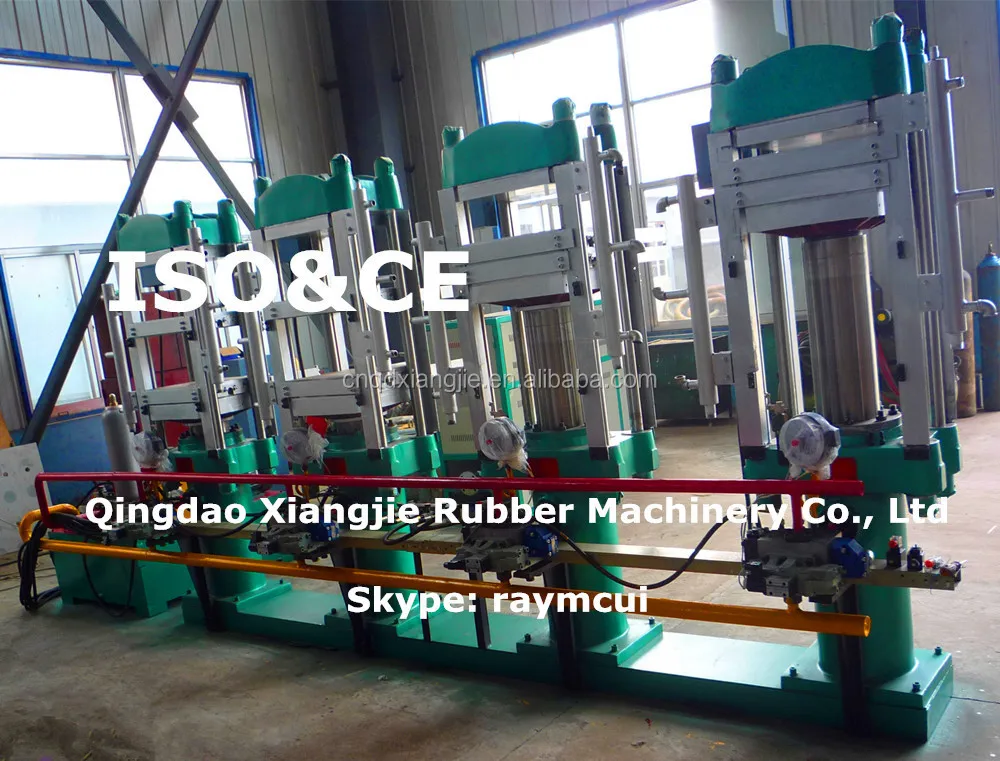

- Поставщик: Qingdao Xiangjie Rubber Machinery Co. Ltd.

Сохранить в закладки 60185100342:

Описание и отзывы

Характеристики

1. The press unit is specially used to produce rubber sole, or small rubber sheet, auto parts, rubber parts.

2. The press unit has 8 sets of presses, which share one central control panel. But for each press, there is one auxiliary individual control panel.

3. Each press can work well individually. They also can work synchronously.

The machine is mounted onto a tray, which is welded with channel steel. And it is fixed with

steel ropes. The packing is suitable for long-term shipment.

We offer the complete machine, as well as the spare parts.

We give one year quality guarantee and long-term technical support. We also can train your

workers for free. If you need, we can install and assemble the machine in your workshop.

And you should pay for the necessary costs, according to the international tradition.

Qingdao Xiangjie Rubber Machinery Co., Ltd has been the professional manufacturer of

rubber machinery for nearly 30 years. Our biggest advantage is we can design and produce

models of plate vulcanizing presses, including the related auxiliary machines, such as

conveyor belt production lines. Besides the presses, we also offer open mixing mill, kneader,

rubber extruder, etc.

We have passed the ISO9001:2000 and CE certification. And we have exported our machines

to many countries and districts, such as USA, Canada, India, Thailand, Viet Nam, etc.

They have gained much praise for their high quality and favorable price.

In order to offer the exact machine to the customers, we usually need the following details:

1. The clamping force

2. The daylight

3. The daylight quantity

4. The piston stroke

5. Your detailed requests are appreciated.

Company profile

Something about Qingdao Xiangjie Rubber Machinery Co., LTD

1.It has been specializing in rubber machinery for 30 years;

2.It is a 100% real manufacturer, rather than a trading company;

3.We give one year quality guarantee and long-term technical support.

Our products have been exported to all around the world, such as America, France, Canada, Australia, Southeast Asia, and the Middle East.

Machining workshop

Certification

1. Features and description

----1. For this type of press unit, 8 presses share one hydraulic station and one center control panel. But there is a small auxiliary control panel for each press.

----2. The press unit can work together. But each press can work normally individually.

----3. This type of press unit is specially designed for rubber sole. The press is matched with manual working table. Besides the rubber sole, other rubber products can be cured, such as rubber slippers and sandals, rubber tile and mat, small rubber parts, etc.

----4. For the piston, the material is chilled cast iron. For the cylinder, it is ductile cast iron. The good material offers long lifetime.

----5. The control system is adopted with PLC and touching screen.

----6. The hydraulic station is adopted with accumulator.

2. Parameters and specifications

Model | XLB-D400×400×2/1.0MN |

Total working pressure(T) | 100 |

Plate size (mm) | 400×400×55 |

Plate unit pressure(Mpa) | 6.2 |

Daylight (mm) | 200 |

Daylight No. | 2 |

Piston stroke(mm) | 400 |

Mould closing speed (mm/s) | ≥15 |

Mould opening speed (mm/s) | ≥15 |

Hydraulic system pressure (Mpa) | 16.0 |

Piston dia. (mm) | Φ285 |

Piston quantity | 1x8 |

Total motor power (kw) | 5.5+5.5 |

Total weight(kg) | 3000x4 |

If you are interested with any rubber machine, please do contact us. We are always here for service.

Похожие товары

Полосатый хлопковый Карманный квадратный сетчатый платок для взрослых и детей для свадебной вечеринки 23*23 см

Дисковый рюкзак для гольфа, изолированный кулер, карман | Дисковые сумки для гольфа с зонтиком

Пружинная шайба DIN127B белый и желтый цинк/горячеоцинкованная Стопорная диск Belleville из углеродистой

Оптовая продажа, полипропиленовый тканевый мешок, рулон для упаковки рисовых зерен, песка, цемента, химических мешков

Гидравлические быстроразъемные фитинги для медных труб и латунный компрессионный шланг тройник фитинг для насоса

Система воздушной помощи ATOMSTACK для лазерного гравировального станка, лазерная резка, гравировка, вспомогательные аксессуары с воздушным потоком

Разъем микро-USB Type-C для подключения док-станции

Новые поступления

Новинки товаров от производителей по оптовым ценам