Печатная плата для кофейного автомата печатная водяного торговая

- Категория: >>>

- Поставщик: Shenzhen Moko Technology Ltd.

Сохранить в закладки 60202201847:

Описание и отзывы

Характеристики

Welcome to MOKO, PCB&PCBA manufacturer, your honest partner!

----over 14 years professional PCB&PCBA Manufacturer

1. PCB fabrication.

2. Turnkey PCBA: PCB+components sourcing+SMD and through-hole assembly

3. PCB clone, PCB reverse engineering.

Our advantage:

1. Free programming and free functional test, free package.

2. High quality: E-test, X-ray, AIO test, QC, 100% funtional test.

3. Professional service. ISO SMT and through hole assembly, over 10 years experience.

4. Certificated: FCC, CE, RoHS, ISO

5. Warranty period: 2 years.

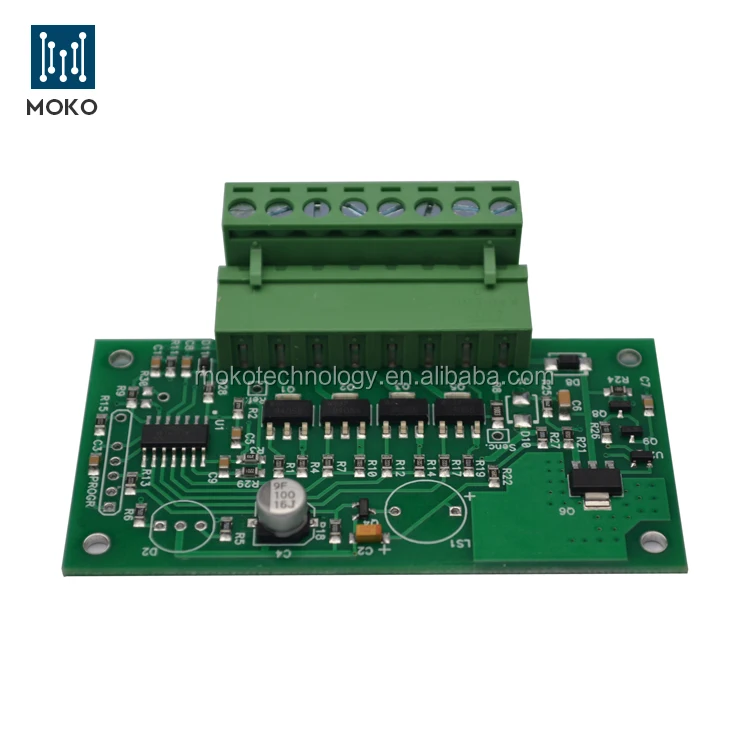

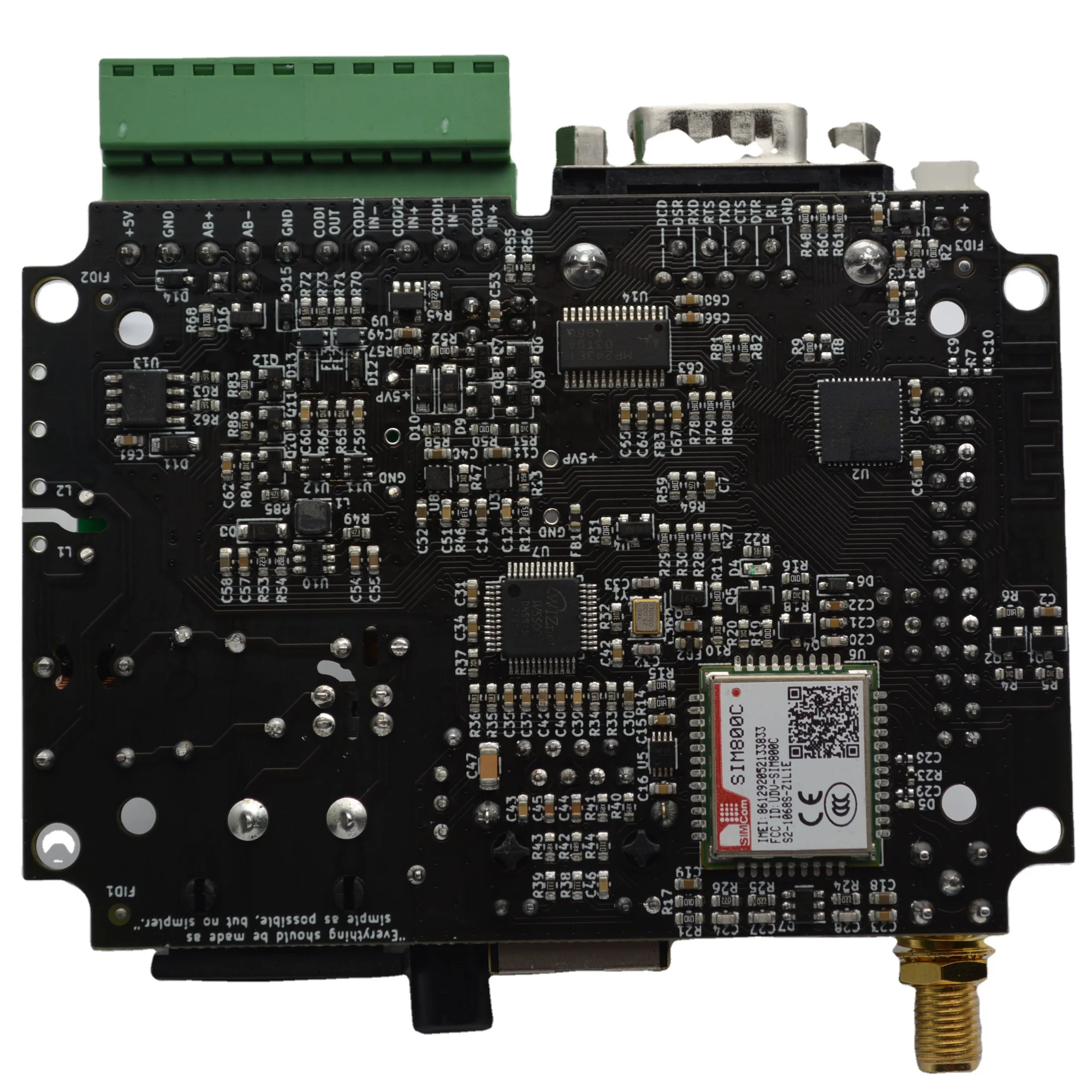

We offer customised vending machine control boards, vending coffee/water machine control boards

MOKO TECHNOLOGY LTD was founded in 2001, located in Shenzhen. We mainly offer Electronics Assembly Service. From our ISO9001:2008 certified factory, we turn out up to 10000 square meter of PCB and 400000 PCBA monthly. For assembly, utilizing 8 high-speed SMT lines from Yamaha and Sony, to meet customers' need.

Moko atended exhibitions every year,

EXPO 2012 Munich, EXPO 2014 Moscow,EXPO 2014 Munich, HK Electronic Fairs,etc

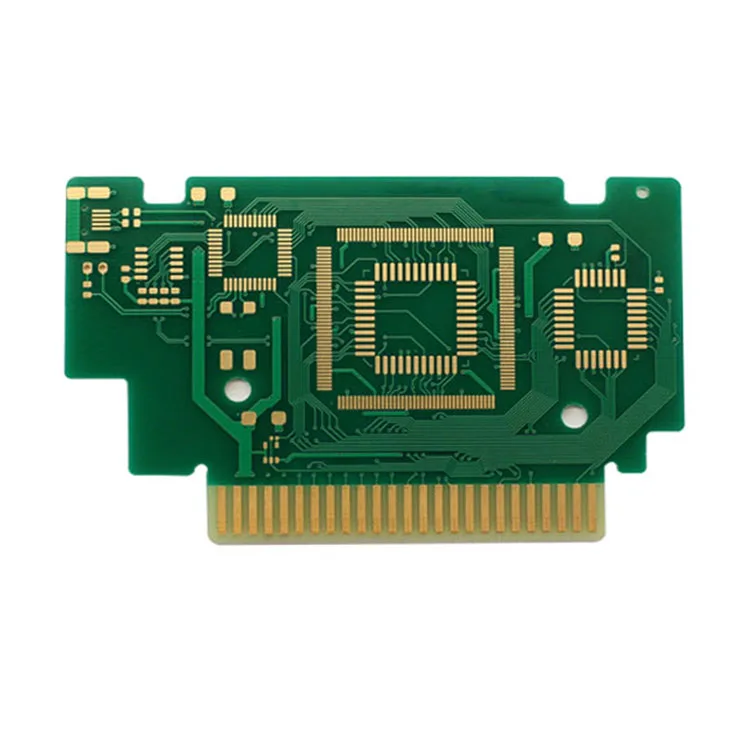

PCB Technical Specification

| Order Quantity | 1-500,000 |

| Layer | 1,2,4,6,upto 18 layer |

| Material | FR-4,glass epoxy,FR4 High Tg,Rohs compliant,Aluminum,Rogers,etc |

| PCB type | Rigid,flexible,rigid-flexible |

| Shape | Any shape: Rectangular,round,slots,cutouts,complex,irregular |

| Max PCB dimensions | 20inch*20inch or 500mm*500mm |

| Thickness | 0.2~4.0mm, Flex 0.01~0.25'' |

| Thickness tolerance | ± 10% |

| Copper thickness | 0.5-4 oz |

| Copper thickness tolerance | ± 0.25oz |

| Surface finish | HASL,Nickle,Imm Gold,Imm Tin,Imm Silver,OSP etc |

| Solder mask | Green, red,white,yellow,blue,black, Double-sided |

| Silk screen | White,yellow,black,or negative, Double-sided or single-sided |

| Silk screen min line width | 0.006'' or 0.15mm |

| Min drill hole diameter | 0.01'',0.25mm.or 10 mil |

| Min trace/gap | 0.075mm or 3mil |

| PCB cutting | Shear,V-score,tab-routed |

Turnkey PCBA Capabilities

| Turnkey PCBA | PCB+components sourcing+assembly+package |

| Assembly details | SMT and Thru-hole, ISO lines |

| Lead Time | Prototype: 15 work days. Mass order: 20~25 work days |

| Testing on products | Flying Probe Test, X-ray Inspection, AOI Test, functional test |

| Quantity | Min quantity: 1pcs. Prototype, small order, mass order, all OK |

| Files we need | PCB: Gerber files(CAM, PCB, PCBDOC) |

| Components: Bill of Materials(BOM list) | |

| Assembly: Pick-N-Place file | |

| PCB panel Size | Min size: 0.25*0.25 inches(6*6mm) |

| Max size: 20*20 inches(500*500mm) | |

| PCB Solder Type | Water Soluble Solder Paste, RoHS lead free |

| Components details | Passive Down to 0201 size |

| BGA and VFBGA | |

| Leadless Chip Carriers/CSP | |

| Double-sided SMT Assembly | |

| Fine Pitch to 0.8mils | |

| BGA Repair and Reball | |

| Part Removal and Replacement | |

| Component package | Cut Tape,Tube,Reels,Loose Parts |

| PCBA process | Drilling-----Exposure-----Plating-----Etaching & Stripping-----Punching-----Electrical Testing-----SMT-----Wave Soldering-----Assembling-----ICT-----Function Testing-----Temperature & Humidity Testing |

ISO SMD and through-hole lines, machines on workshop

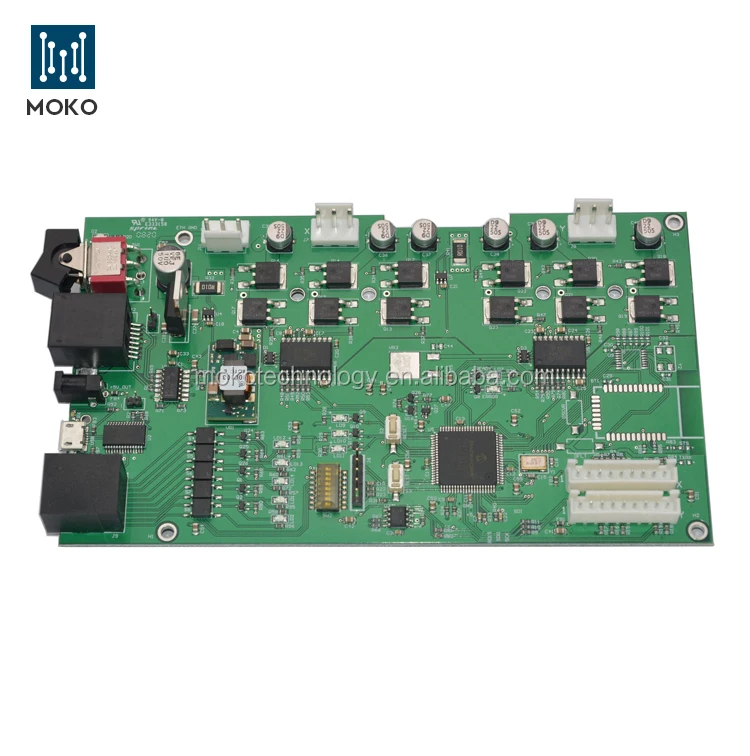

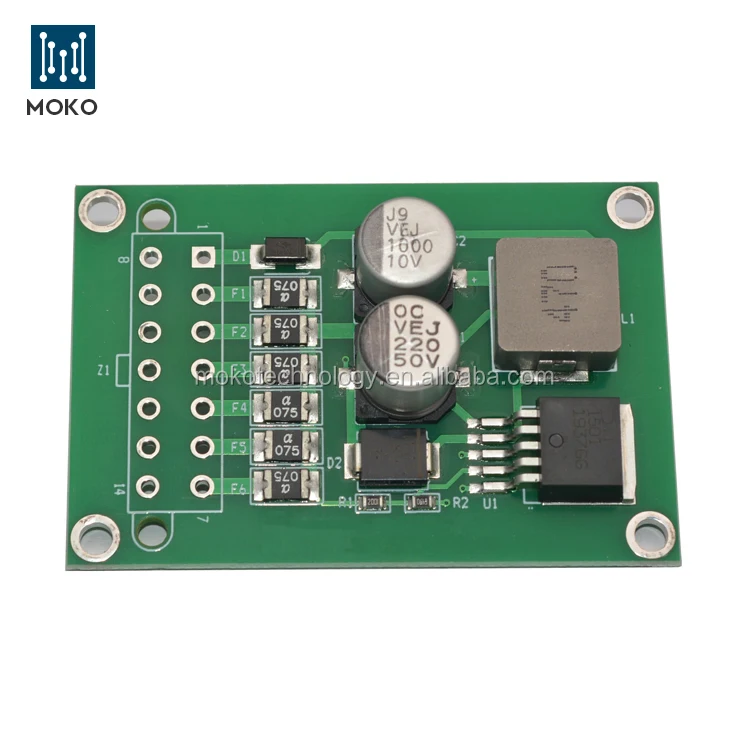

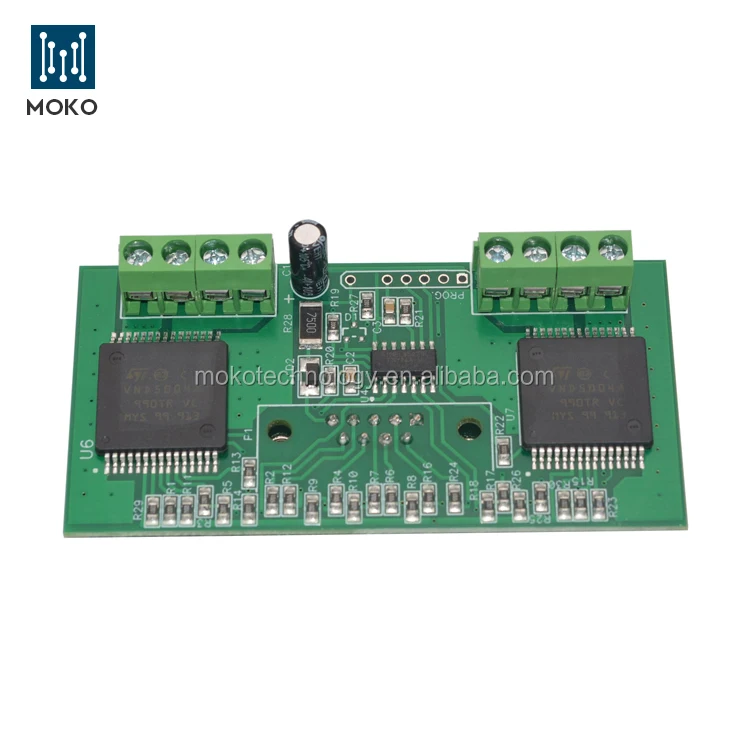

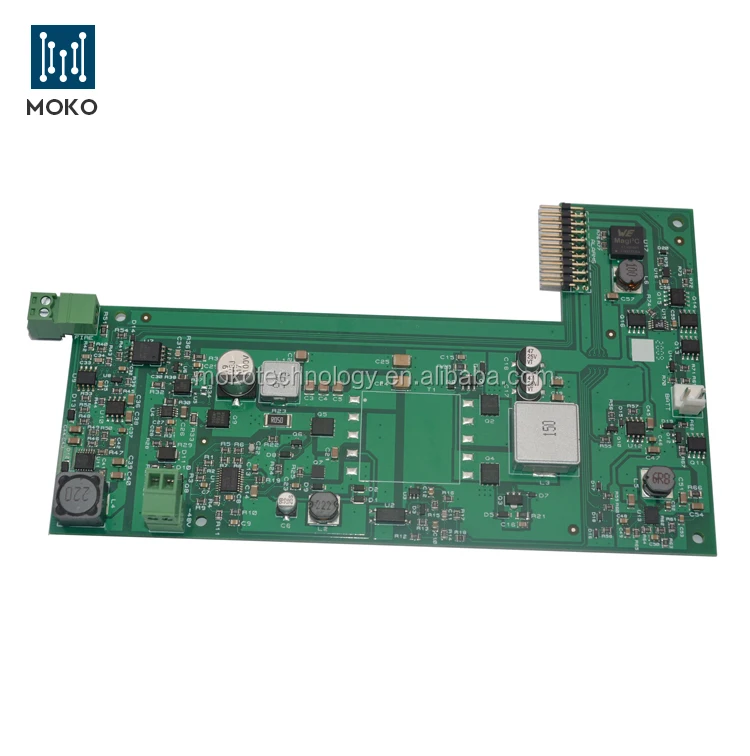

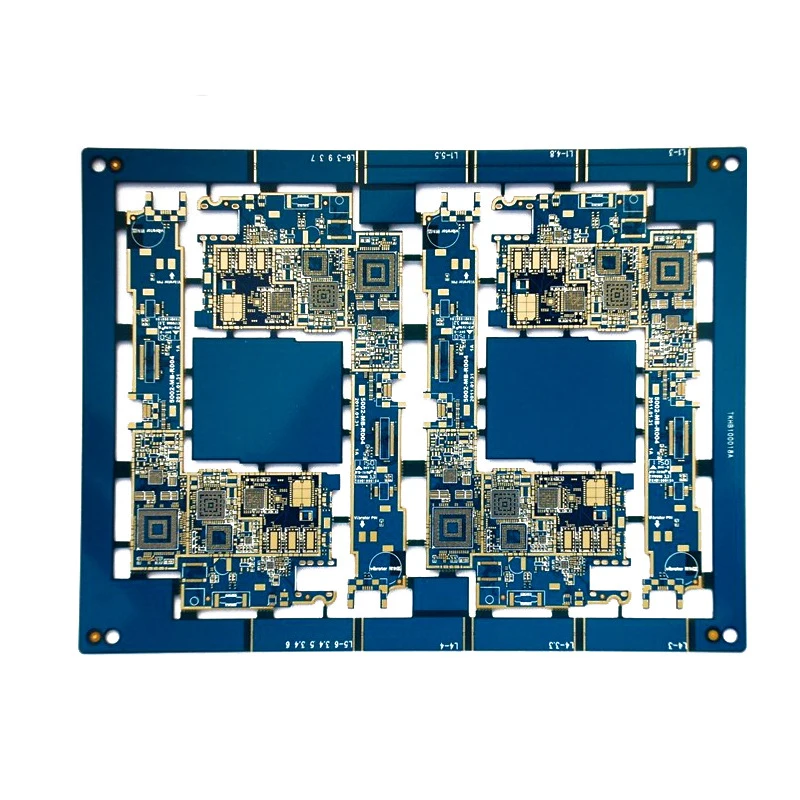

PCB&PCBA Products Show

PCBA from samples to mass production:

PCBA manufacturing steps:

Vending machine control board

QC: Free functional test, AOI test, free functional test, 2 years warranty period

Packing details:

PCBA are packed into plastic bags. Plastic bags in a small carton. 4 small carton into a big carton.

A big carton with MOKO logo: 35×32×40 cm size.

Shipping Express:

FedEx, DHL, UPS, TNT, EMS, private lines, etc.

Air freight, Sea shipping

Q: What files do you use in PCBA fabrication?

A: Gerber or Eagle, BOM listing, PNP and Components Position

Q:Is it possible you could offer sample?

A: Yes, we can custom you sample to test before mass production

Q: When will I get the quotation after sent Gerber, BOM and test procedure?

A: Within 6 hours for PCB quotation and around 24 hours for PCBA quotation.

Q: How can I know the process of my PCBA production?

A: 7-10 days for PCB production and components purchasing, and 10 days for PCB assembly and Testing

Q: How can I make sure the quality of my PCBA?

A: We ensure that each piece of PCBA products work well before shipping. We'll test all of them according to your test procedure. Also if there are any defect items during the shipping, we also can be free to repair for you.

Похожие товары

Электронные плюшевые игрушки pcb Печатные Платы Сборка потребительских электронных игрушек сборка pcb фабрика

Слоистый пластик с медной фольгой печатная плата cem-3 fr4 fr2 0,2 мм толщина 94v0 pcb

HDI PCB для смартфонов и планшетов FR4 CEM-1 CEM--3

Новые индивидуальные lifepo4 батарея 12 В 18650 электрический мотор аккумулятор 100ah с MSDS UN38.3

Электронный CEM-1 двусторонняя PCB програмная панель рисунок печатной фабрики

Горячие продажи по ограничению на использование опасных материалов в производстве Cem-1 Fr4 печатные платы для продажи

Сборная электронная печатная плата 94v0 Pcba на заказ от китайского производителя

Новые поступления

Новинки товаров от производителей по оптовым ценам