Цементный шлифовальный блок Клинкерного цементного завода цементная печь цементный

- Категория: Cement Making Machinery >>>

- Поставщик: Henan Zhengzhou Mining Machinery Co. Ltd.Henan Ltd.

Сохранить в закладки 60206577710:

Описание и отзывы

Характеристики

Portlant Cement Process Routing

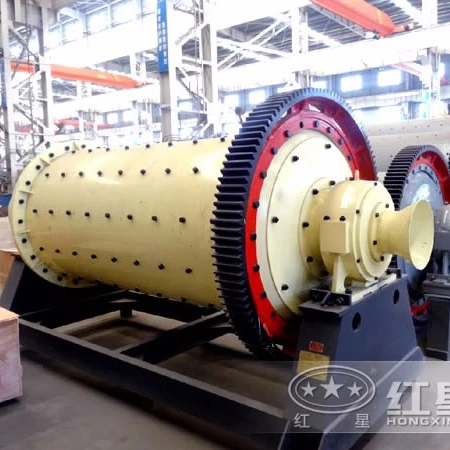

Cement Grinding Unit

We provide the whole service of design manufacture and installation, EPC project or parts equipment. We design and manufacture devices for new type dry method cement production line, which capacity from 300t/d to 2000t/d clinker. And we can also assist the client in transacting purchaser`s credit or Chinese government`s credit while exporting.

Rotary kiln is the main equipment for sintering cement clinker. The rotary kilns produced by our company can be divided into dry process and wet process. They can also be used for chemical industry, metallurgy industry and etc. Throught technical renovations, the rotary kiln sintering system equipment made by our company has adopted high measuring precession plunger pump, variable speed adjusted valve, contact graphite block air seal and other national advanced technologies. In order to raise up automation degree, indurstrial TV has been used at the kiln head for monitoring of kiln, analog fluorescent screen has been used for display of process flow; Infrared scanning system has been adopted for sintering zone to directly reflect the burning conditions on the computer. With the use of these new technologies, it is directly in vision, convienent in operation and reliable in use. Therefore, the rmalcondition can be raised. Compared to been raised 3-5% up, production has been increased 5-10% and heat consumption has been reduced 15% down.

Rotary kiln belongs to building material equipment, which can be divided into cement kiln, metallurgy chemical kiln and lime kiln according to different materials.

Cement kiln is used for making of cement clinker and there are dry and wet methods to make cement. metallurgy chemical kiln is used for magnetic roasting of iron ore and oxidizing roasting of chrome and nickel in the steel factory; baking high-alumina mine in the refractory material factory; baking chamotte and alumina in the aluminium factory and baking chrome ore and chrome powder in the chemical plant.

Lime kiln is used for baking active lime and dolomite in the steel factory and ferroalloy factory.

cement production line ,We provide the whole service of design manufacture and installation.,EPC project,from the maket research ,site slection ,feasibility analysis ,equipment ,installation and training or only parts equipment.

Process of cement production line:

1.Raw Materials

The main raw materials used in the cement manufacturing process are limestone, sand, shale, clay, and iron ore. The main material, limestone, is usually mined on site while the other minor materials may be mined either on site or in nearby quarries. Another source of raw materials is industrial by-products. The use of by-product materials to replace natural raw materials is a key element in achieving sustainable development.

2.Raw Material Preparation

Mining of limestone requires the use of drilling and blasting techniques. The blasting techniques use the latest technology to insure vibration, dust, and noise emissions are kept at a minimum. Blasting produces materials in a wide range of sizes from approximately 1.5 meters in diameter to small particles less than a few millimeters in diameter.

Material is loaded at the blasting face into trucks for transportation to the crushing plant. Through a series of crushers and screens, the limestone is reduced to a size less than 100 mm and stored until required.

Depending on size, the minor materials (sand, shale, clay, and iron ore) may or may not be crushed before being stored in separate areas until required.

3. Crushing and Pre-homogenization.

Crushing. During producing concrete, most of the raw materials must be first crushed before being used to make concrete. Among these raw materials which include lime stone, clay, iron ore and coal, etc. the lime stone is of the greatest usage to make concrete. With comparatively larger particles and higher hardness, crushing the lime stone to required fineness after mining is of relatively important consequence among crushing all those raw materials. There are many crushers used in crushing these raw materials, such as jaw crusher, impact crusher, cone crusher and vertical shaft impact crusher, etc. According to the raw materials' different particles and hardness, there are several suitable crushers which can be used in the crushing.

Pre-homogenization of raw materials.

4. Raw material Homogenization.

In the process of new dry concrete production, the stability of pit entry clinker raw material component is the premise of the whole system. Raw material homogenization system plays very important role in the stability of pit entry clinker raw material component.

5. pre-heater and calciner

6. The burning of concrete clinker.

7. Grinding

Grinding is the last process of cement produce and also is the most current consuming working procedure. Cement clinker get grinded into the right size. The smaller the particle size is, the better the final cement is.It's important to choose suitable grinding machine.8. Concrete Packaging.

Henan Zhengzhou Mining Machinery Co., Ltd. is founded in 1956. Company specialized in manufacture, design and installation of cement plant and mining processing equipment. The company is nominated as the national supplier of cement and mining plant by Chinese State Ministry of Machine Building Industry.

Have powerful ability in making design for:- Cement Plant

- Quicklime Plant

- Magnesium Calcination Plant (Chinese Industrial Equipments' Standard Maker)

- Mining Processing Plant

- Ceramic proppant and LECA Line

- Refractory material calcination and bauxite calcinations.

- Mineral ore beneficial line

Products contain:1, Calcination Equipments: preheater, rotary kiln, cooler.2, Mining Processing: Ball mill, magnetic separator, flotation, dryer.3, Crushing Equipments: Jaw crusher, impact crusher, hammer crusher.4, Related Equipments: Feeder, belt conveyor, bucket elevator,dryer, etc.With advanced technology, high quality equipment, powerful technical support and scientific management, ZK CORP are able to provide best solution for customer’s project. Our key company culture features Morality, Sincerity and Exquisite workmanship. We will exert ourselves in the pursuit of the customers’ success, the staff’s welfare and the society’s development.ZK Manufacturing Capacity:

Main Equipments Drawing:

ZK Certifications;

Provide considerate services to minimize clients' worries.

(1) Assist clients to prepare for the first construction scheme;

(2) Install and debug the equipment;

(3) Train the first-line operators on site;

(4) Examine the equipment regularly;

(5) Take initiative to eliminate the troubles rapidly at site;

(6) Distribute the guarantee fittings door-to-door;

(7) Provide perfect service;

(8) Provide technical exchanging;

(9) Provide maintenance for big items.

ZK’s PROMISE: The products quality is the life of ZK Company. We take in high quality raw materials, durable parts and advanced manufacturing process to make equipments, so that we can provide durable and long using life equipments. ZK’s considerate services, meticulous manufacture and satisfying price make clients relieved.

Customer oriented, ZK provides overall service;

Service is the core of work, ZK makes custom-made products;

Quality is our focus, best quality from reliable ZK.

Service routing: from pre-sales to after-sales, ZK consider clients’ benefit at first. ZK service target is seeking detailed refinement to satisfy clients.

Pre sales:

1. Inquiry, visiting, negotiation.

2. Professional team of engineers provides suggestions for equipments choice.

3. Professional team of engineers provides best solutions and routing for clients’ program.

4. ZK R&D Department and Technical Department will provide special design and nonstandard parts for clients’ actual conditions and demands.

5. Skilled workers manufacturer production on advanced lathes according drawings strictly.

In sale:

1. Strict QC bases on international standard/

2. Help clients make installation plan and construction scheme.

After-sales service:

1. Professional technicians provide installation and deducts service on-site.

2. Free training for clients’ staff.

3. After sales tracking and quick response for problems.

Provide Professional transportation plan and packaging service.

Contact me and ask for Questionair List. It is my honour to take part in your program!

Похожие товары

Вертикальная мельница износостойкая облицовочная плита, запасные части для оборудования для производства цемента

Горячая Распродажа цементный охладитель боксита обжига ротационная печь

Роторная сушилка для древесных опилок

Small Scale Sponge Iron Charcoal Rotary Kiln/used Kiln for Sale/rotary Pyrolysis Biochar

Lo mas vendido 2023 Hongxing Прямая продажа с фабрики небольшая мини-шаровая мельница называемая переливающейся Золотой шаровой мельницей

Ведущие производители цементных заводов на продажу

Вращающаяся печь для обжига бокситов 87% непрямого огня

Новые поступления

Новинки товаров от производителей по оптовым ценам