Усовершенствованный автоматический аппарат для сварки труб локтя сверхмощный Автоматический сварочный раствор промышленного применения

- Категория: Трубосварочный станок >>>

- Поставщик: Nanjing Auto Electric Co. Ltd.Nanjing Ltd.

Сохранить в закладки 60213404467:

Описание и отзывы

Характеристики

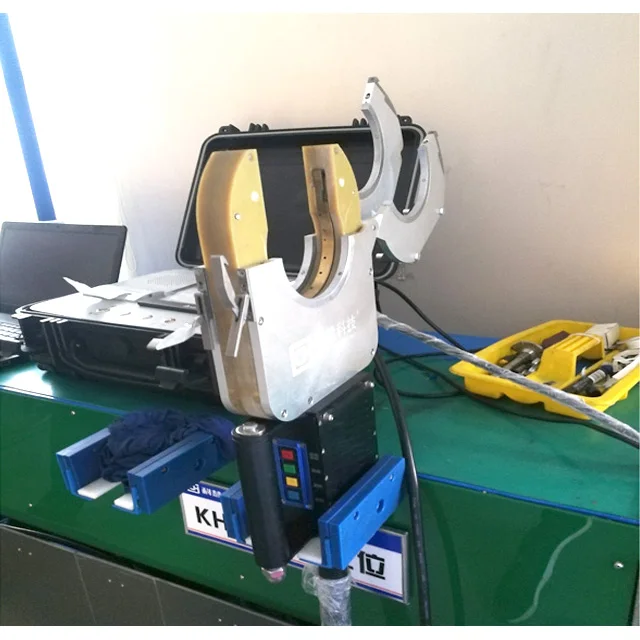

Advanced AUTO Elbow Pipe Welding Machine Heavy-Duty Automatic Welding Solution For Industrial Applications

It has features as following:

1.Three models available ( 32”type, 48” type,60”type);

2.Suitable for C.S/S.S/Alloy S., etc.;

3.Suitable for elbow welding;

4.Suitable for long pipe welding;

5. TIG/MIG/SAW are optional;

6. PLC system control & WPS program;

7. Zero-balance weight paten design: suitable for max. weight of elbow is 1.5T;

8. Welding speed adjustable and stepless;

9. Higher welding quality and efficiency, for example, for a 32” type automatic pipe welding station, it can reach 175-185DI/day productivity, including handling, presetting time.

Technical Data:

| 1 | Model | AUTO PPAW830-A |

| 2 | Input Voltage | 3PH AC380/400v,50/60HZ |

| 3 | Input Power | 38KW |

| 4 | Pipe Diameter Range | DN100~DN800mm |

| 5 | Rotating Speed Range | 50~500m/min |

| 6 | Elbow Radius | 1.5 Multiple |

AUTO Heavy-duty Automatic Elbow Welding Machine is applicable to weld heavy duty pipes with thick-wall, such as long pipe and fittings welding, or long pipe to pipe welding when match pipe supporter, including pressure head type welding machine, supporting rotator, pipe supporter, and Rail Skids.

To overcome eccentricity of pipe fitting, this station is designed and equipped with peculiar compaction devices which can realize steady turning of workpiece. By working together with specially designed pipe supporter, it can easily execute welding on the joint of long straight pipe. Application of this system can greatly improve welding automation, decrease labor intensity, and enhance welding quality and efficiency. Machines with specific requirements can be customized.

There are more than 40 sets of WPS program stored in the control system. Through the touch screen the operator just need to select the welding procedure to be used for various diameters of pipes with different wall thickness. And it can use T.I.G, M.I.G, or S.A.W welding process for joint automatic root pass, fill and cap pass welding.

It is widely used in the industry of oil and gas, refinery, petro-chemical, shipping building, offshore, power plant, nuclear plant, etc.

Pipe Spool Fabrication Machines

| 1 |  | Pipe Cutting& Beveling All-in-one Machine >Suitable for pipes not larger than 8”,max.thickness:20mm >Cutting efficiency:100times/8hrs >PLC control with automatic measuring to guarantee the same processing cycle >Widely used for small bore C.S/S.S production lines |

| 2 |  | High Speed Band-saw Cutting Machine >Three models available(16”type,24”type”,48”type) >PLC system control;self-measuring function with precision:±0.5mm >Using hydraulic self-centering chuck >It only takes 6 minutes to cut a 24” pipe of 25mm thickness >Widely used for C.S/S.S production lines. |

| 3 |  | High Speed CNC Pipe End Beveling Machine >Automatic self-centering chuck >Single V,double V,U type bevel >Can be matched with pipe end turning devic >High speed beveling:for example,it only takes 2.5minutes to get a 37.5 degree bevel for a S.S pipe end(diameter :610mm,thickness:25mm) >Several models available:16”,24”,32”,48” |

| 4 |  | Two / Multi- Axis CNC Flame/Plasma Cutting Machine >Five/multi-axis cutting machine can profile more complicated outlines with various bevel type >Standard machine suitable for pipes nor larger than 24'' |

| 5 |  | Multi-function Pipe Fitting-up Station >Suitable for flange,elbow,tee,reducer to pipe and special T-joint fitting-up. >Light-duty type(manual) and heavy-duty type(motorized) are available. >Different types available, 8" type, 24" type, 32" type, 48" type, 60" type |

| 6 |  | Automatic Pipe Welding Station >With two welding heads >TIG/MIG/SAW are optional >PLC system control & WPS programmed >Max. efficiency fo reach welding head can be 400D.I/8hrs even use TIG/MIG technology. >Different types available, 8" type, 24" type, 32" type, 48" type, 60" type |

| 7 |  | >used for pipe convenient transporation during in pipe spool fabrication. >Its speed is adjustable between 2M to 20M/min. |

Похожие товары

Аппарат для электрофузионной сварки haina HDPE труб

Орбитальная трубка к сварочной машине

SST-160 инструмент для подвешивания сварочного аппарата PPR 63 -160 мм

Хорошая цена PF315 90-315 гидравлический аппарат для сварки пластиковых труб

Высококачественный PF315 90-315 гидравлический аппарат для сварки пластмассовых труб

Горячая Распродажа PF315 90-315 гидравлический аппарат для стыковой сварки пластиковых труб Hdpe vfor sale

Автоматический сварочный аппарат

Новые поступления

Новинки товаров от производителей по оптовым ценам