Резиновый упругий кронштейн для рулевых колес DIN из ковкого чугуна/чугунного затвора с дренажным клапаном

- Категория: >>>

- Поставщик: Beijing Voflo Valves Co. Ltd.

Сохранить в закладки 60251369911:

Описание и отзывы

Характеристики

DIN Standard Handle Wheel Rubber Resilient seated ductile iron/cast iron Gate Valve with Drain

- This gate valve allows for two – way flow direction and used for closing or opening the medium flow. This valve can be installed in horizontal and vertical positions in the piping systems.

- The valve adopts full – shut structure which has good protection function and can be used in all weather.

- Can use all sorts of pipg flange standards and flange seal face form, meet various needs of the project and use requirements.

Flat plate design, floating seats, bypass design, all lead to lower operating torque.

The sealing surface of the valve adopts abrasion- resistant and anti-corrosive materials which can lengthen the performance life of the valve.

The wedge is replaceable without needing to remove the valve from the pipelines.

- It is designed with straight through bore type with non-rising stem, inside screw and bolted bonnet. This valve provides positive shutoff with inimal pressure drop and flow turbulence.

Size: DN50 – DN600 (2” – 24”)

Standard:

- Design and manufacture: DIN3352

- Test and inspection: EN12266

- Face to face (end to end): DIN3352 F4, DIN352 F5

- Flanged connection: DIN 2501 PN10&PN16

Application:

It is widely used in process industries such as palm oil and refinery plant, fire protection system and cooling system, tap water industry, sewage treatment, shipping construction, petroleum, chemicals, food, pharmacy, textile, electric power, metallurgy and energy system’s pipeline to adjust and shut off fluids.

Working Pressure: 10bar/ 16bar

Testing Pressure:

Shell: 15bar/ 24bar

Seal:11bar/ 17.6bar

Materials of main part:

Name | Material | Specification |

ASTM | ||

Body | Cast Iron | ASTM A126B |

Ductile Iron |

| |

Disc | Ductile Iron | ASTM A536 |

Stem nut | Carbon Steel | A216 WCB |

Bolt | Carbon Steel | A216 WCB |

Washer | NBR |

|

Bonnet | Ductile Iron | ASTM A536 |

O-Ring | EPDM |

|

Washer | NBR |

|

Conca | Carbon Steel | A216 WCB |

O-Ring | EPDM |

|

Dust-Ring | EPDM |

|

Stem | Stainless Steel | A276-410 |

Hand Wheel | Ductile Iron | ASTM A536 |

Washer | Carbon Steel | A216 WCB |

Bolt | Carbon Steel | A216 WCB |

« Other special material requested, please contact us directly.

Connecting dimensions (Unit:mm)

SIZE | DIMENSSIONS LDIN3352, F4/ F5 | DIN2501 PN16 | DIN2501 PN10 | ||||||

L(F4) | L(F6) | D | H | SL | D | N- | D | N- | |

DN50 | 150 | 250 | 165 | 320 | 145 | 125 | 4-18 | 125 | 4-18 |

DN65 | 170 | 270 | 185 | 360 | 145 | 145 | 4-18 | 145 | 4-18 |

DN80 | 180 | 280 | 200 | 390 | 175 | 160 | 8-18 | 160 | 8-18 |

DN100 | 190 | 300 | 220 | 450 | 175 | 180 | 8-18 | 180 | 8-18 |

DN125 | 200 | 325 | 250 | 490 | 245 | 210 | 8-18 | 210 | 8-18 |

DN150 | 210 | 350 | 285 | 560 | 245 | 240 | 8-23 | 240 | 8-23 |

DN200 | 230 | 400 | 340 | 660 | 295 | 295 | 12-23 | 295 | 8-23 |

DN250 | 250 | 450 | 405 | 760 | 355 | 355 | 12-27 | 350 | 12-22 |

DN300 | 270 | 500 | 460 | 850 | 355 | 410 | 12-27 | 400 | 12-22 |

DN350 | 290 | 550 | 520 | 1100 | 460 | 470 | 16-27 | 460 | 16-22 |

DN400 | 310 | 600 | 580 | 1200 | 500 | 525 | 16-30 | 515 | 16-26 |

DN500 | 350 | 700 | 715 | 1480 | 550 | 650 | 20-30 | 620 | 20-26 |

DN600 | 390 | 800 | 840 | 1608 | 550 | 770 | 20-36 | 725 | 20-30 |

company profile

1. Small in size and light in weight, easy to install. It can be mounted wherever needed, suitable for various actuators.

2. Simple, compact structure, quick 90 degree on-off operation.

3. Disc has two-way bearing perfect seal, without leakage under the pressure test.

4. Flow curve tending to straight-line. Excellent regulation performance.

5. Various kinds of materials, applicable to different medium.

6. Strong wash and brush resistance and can fiit to bad working condition.

7. Center plate structure, small torque of open and close.

8. Long service life. Standing the test of 10000 times opening and closing operation.

9. Can be used in cutting off and regulation medium.

10. Disc & stem are fastened by pin, more stable.

Похожие товары

Цветной высококачественный однослойный ТПЭ Резиновый пенопласт для Ковриков Для Йоги

Многоразовый шпатель из нержавеющей стали, скребок для торта в инструментах для выпечки и кондитерских изделий

Высококачественный водонепроницаемый УФ-блокирующий выдвижной складной алюминиевый тент

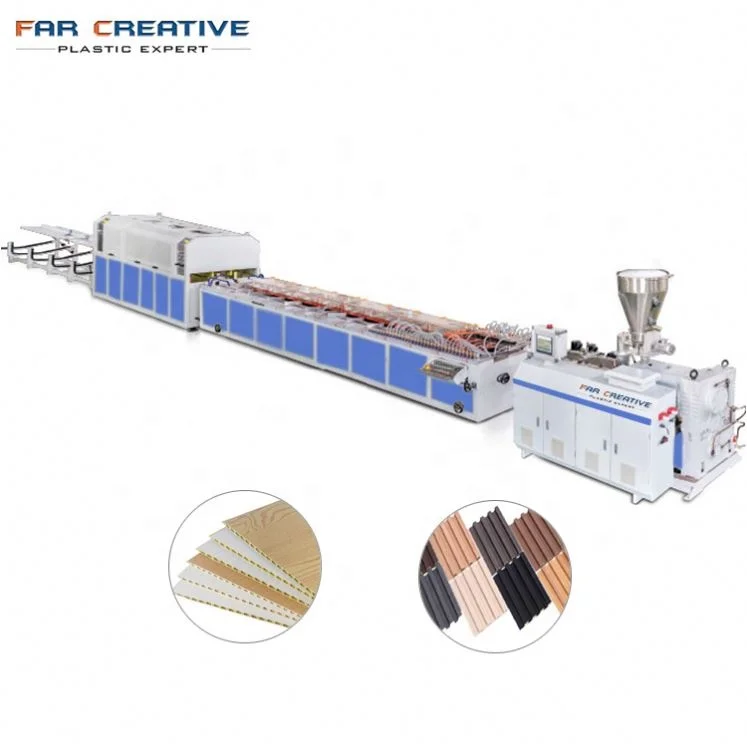

Машина для производства потолочных панелей из ПВХ с новым дизайном, низкая цена

Полностью автоматическая туннельная Автомобильная стиральная машина с надежным качеством

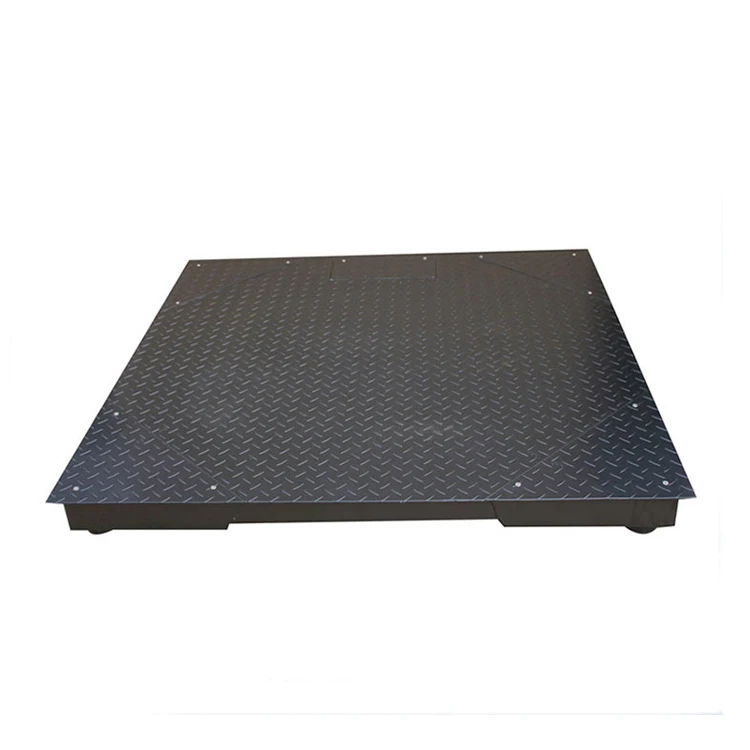

Электронные весы с промышленной платформой 1000 кг

Модный мраморный агатовый камень, подставка для чашки «сделай сам», подставка для таблеток, подставка под чашку с золотой границей

Новые поступления

Новинки товаров от производителей по оптовым ценам