Завод по производству гипсового

- Категория: >>>

- Поставщик: Zhengzhou Shuguang Heavy Machinery Co. Ltd.Zhengzhou Ltd.

Сохранить в закладки 60258273315:

Описание и отзывы

Характеристики

The whole production line for making gypsum powder |

| Brief Introduction |

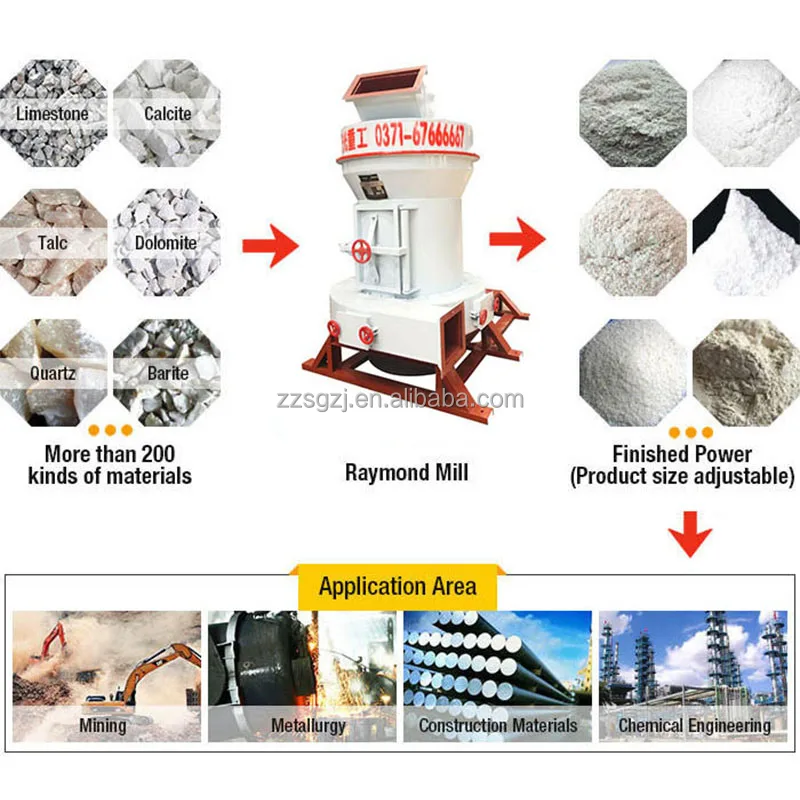

1.Application: paint,pipe,cosmetics,plastic parts,floor etc

2.Suitable materials: gypsum,talc,calcite,limestone,marble,dolomite,iron ore,cement,granite,clay,kaolin and so on( nonflammable and non-explosive materials with humidity below 6% and Mohs hardness less than 7)

3.Feed size:≤25mm (if you material is big,please add a jaw crusher)

4.Outlet size:60-325 mesh(if you need other fineness,we also have other type mill,please contact)

5.The whole production line include:jaw crusher,elevator,hopper,feeder,raymond mill,electric cabinet etc.

6.Power:Different modes is different,please contact us and ask. gypsum powder production plant

Technical Parameters |

Model | 3R3015 | 3R2715 | 3R2615 | 3R2115 |

Feeding size(mm) | ≤25 | ≤25 | ≤20 | ≤15 |

Fineness of finished product(mm) | 0.125-0.044 | 0.125-0.044 | 0.125-0.044 | 0.125-0.044 |

Production(t) | 1-4 | 0.9-3.5 | 1.7-3 | 0.5-2 |

Speed of axis(r/min) | 160 | 160 | 160 | 180 |

Dia of Ring (mm) | 860 | 830 | 780 | 650 |

Dia of Roller(mm) | 300 | 270 | 260 | 210 |

Roller height(mm) | 150 | 150 | 150 | 150 |

Main motor (KW) | Y225m-8-22 | Y225m-8-22 | Y225s-8-18.5 | Y200L-8-15 |

Fan motor (KW) | Y180m-4-22 | Y160L-4-18.5 | Y160L-4-15 | Y160m-4-11 |

Analysis motor(KW) | Y112m6-2.2 | Y112m6-2.2 | Y112m6-2.2 | Y112m6-2.2 |

Model | 6R4525 | 5R4121 | 5R4119 | 4R3218 | 4R3216 |

Feeding size(mm) | ≤30 | ≤30 | ≤25 | ≤30 | ≤30 |

Fineness of finished product(mm) | 0.125-0.044 | 0.125-0.044 | 0.125-0.044 | 0.125-0.044 | 0.125-0.044 |

Production(t) | 13-40 | 8-15 | 5-10 | 2.5-9 | 2-8 |

Speed of axis(r/min) | 82 | 105 | 105 | 130 | 130 |

Dia of Ring (mm) | 1620 | 1270 | 1270 | 970 | 970 |

Dia of Roller(mm) | 450 | 410 | 410 | 320 | 320 |

Roller height(mm) | 250 | 210 | 190 | 180 | 160 |

Main motor (KW) | Y315m-4-132 | Y280s-4-75 | Y280s-4-75 | Y225s-4-37 | Y225s-4-37 |

Fan motor (KW) | Y315m-4-132 | Y250m-4-75 | Y250m-4-75 | Y200L-4-37 | Y200L-4-37 |

Analysis motor | Y160m-4-11 | Yc200-4-7.5 | Yc200-4-7.5 | Yc120-4-5.5 | Yc120-4-5.5 |

| Whole production line introduction |

| Raymond mill structure and working principle |

Working Principle of Raymond Mill (Grinding Mill):

A.Raw material is crushed by jaw crusher to the size required which is suitable for the Raymond Mill (Grinding Mill) ,

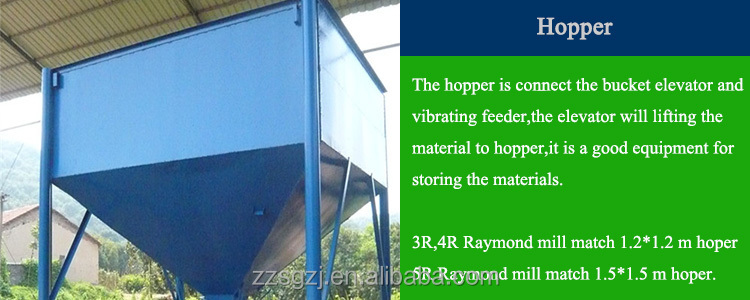

B.Then the crushed materials are elevated into a hopper from which the material is transported through the electro-magnetic vibrating feeder evenly and continuously into the grinding chamber for grinding mill. The rollers oscillate outward to press the ring because of the centrifugal force and the shovel scoops up the materials, send to the middle between ring and roller to accomplish the grind.

C.After this, the ground stuff are carried by the air from the blower into the powder separator (Analyzer Machine) for screening. The fine powers are blow into the cyclone powder collector and are poured out through the output-powder valve as the final products, and the corase stuff after the screening will be recycled back into the grinding chamber for regrinding. The set’s airflow system is closely sealed up and circulated under condition of negative and positive pressure.

| Customer working site and visit |

| Delivery pictures |

| About Us |

Zhengzhou ShuGuang Heavy Machinery Co.,Ltd

1.Zhengzhou Shuguang Heavy Machinery,founded in 1993,is an integral system that produce R&D,production and sales.

2.We are located in 19th,Longjiang west road,Shangjie district,Zhengzhou city,Henan,China.

3.Our Company produce Raymond mill,Superfine Grinding mill,Three ring micro powder mill,Rotary dryer,Ball mill,Jaw crusher,Impact crusher,Hammer crusher,Cone crusher,Coal gasifier,Vibrating Scree,Vibrating Feeder,stone and sand production line etc.

4.Our products are well known to the international market such as America,Italy,Chile,Sri Lanka,Australia And so on.

5.We warmly welcome and expect strong support from more customers,We believe that science and technology create brand and integrity creates glory.We will serve and repay our society as always be more excellent products.

| Contact Us |

If you are looking for this machine,please contact us now!

we would like to send you more details and best price,in order to save your time,at the same time,please tell us your requirement:

such as material type,capacity,material size,fineness and so on,thanks! gypsum powder production plant

We are looking forward to your inquiry !

Похожие товары

Крытый садовый гидропонный ковш 5 галлонов стойка для прорастания семян 4 яруса

Пальмовые деревья с датой 4 метра оптовая продажа пальмовых деревьев искусственной Саудовская

Алюминиевый набор геодезических купольных палаток для отдыха в

Автоматический Сварочный позиционер вращающийся стол отверстие 100 мм для токарной сварки

Высококачественная прозрачная водостойкая самоклеящаяся Золотая фольга с рисунком колы-соды наклейки на

Оптовая продажа мужские хлопковые брюки из спандекса повседневные спортивные на

Китайский поставщик серебряная Роскошная пластиковая косметическая бутылка пустая безвоздушная Косметическая упаковочная 15 мл 30

Новые поступления

Новинки товаров от производителей по оптовым ценам