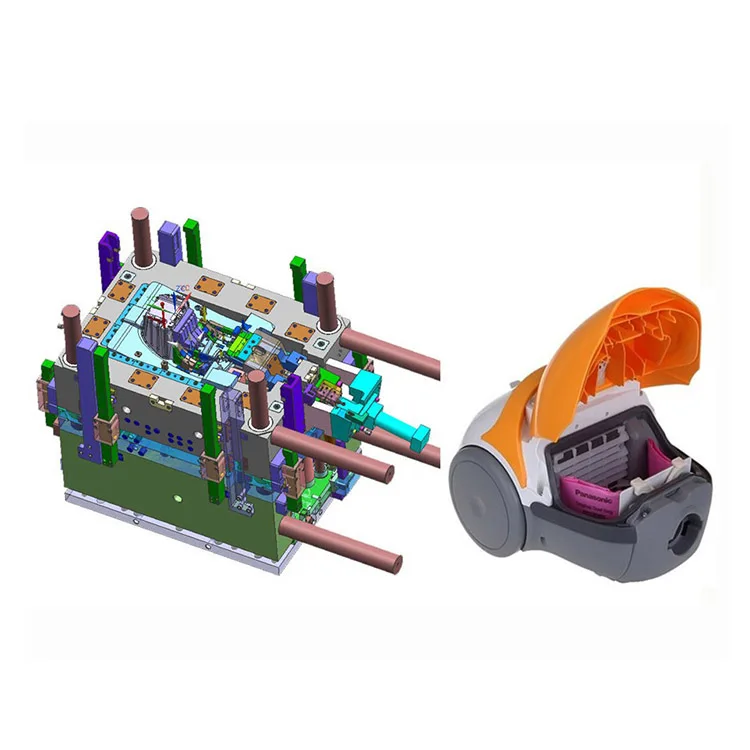

Лидер продаж 2019 производство пылесосов пресс формы

- Категория: >>>

- Поставщик: Taizhou Huangyan Chenhang Mould Factory

Сохранить в закладки 60308358675:

Описание и отзывы

Характеристики

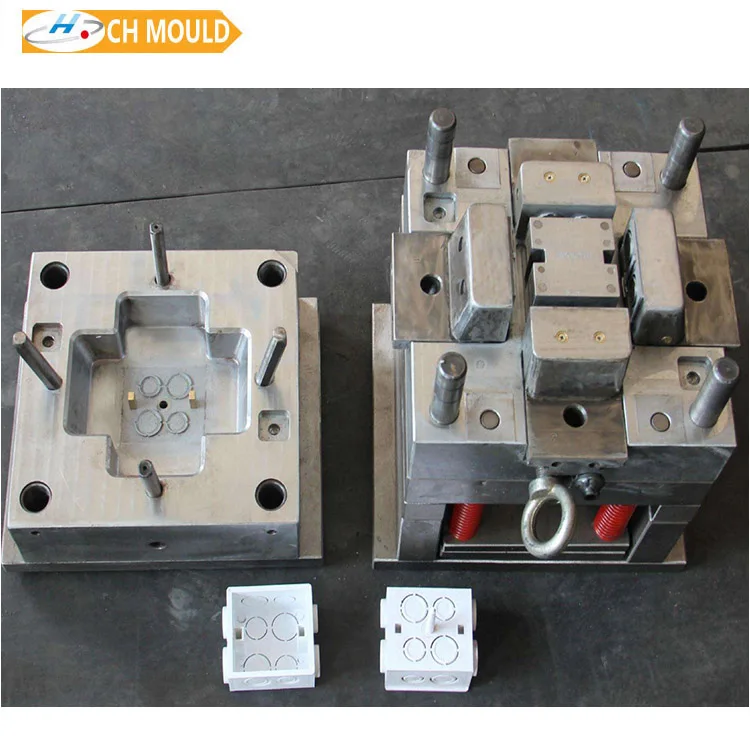

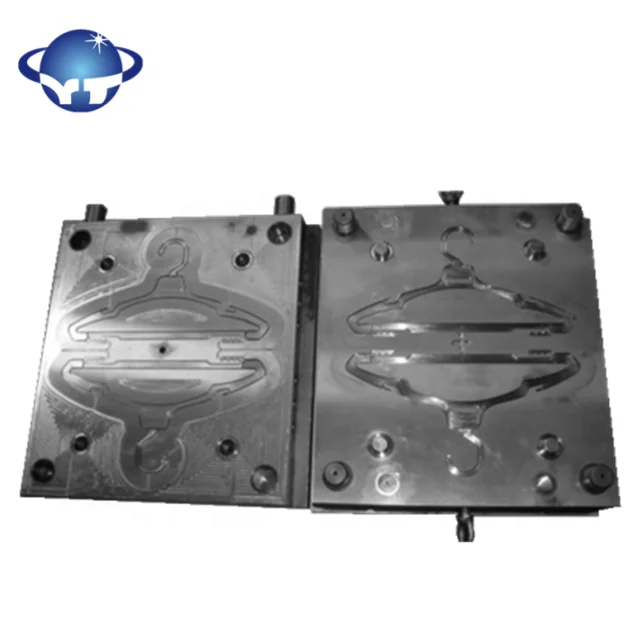

Mold Name | plastic mould manufacturer of garden armrest chair |

Mould Shaping | injection mold |

De-mould Type | Automatic Eject |

Mould material | P20,45#, 50#, H13, 718, 2738, NAK80, S136, SKD61 etc. |

Mould base | 45#/according to customer’s requirements/ subject to specific mould |

Mould Cavity | Single/multi |

Sprue Gate | Hot Runner/Cold Runner |

Design software | UG, PROE, CAD, CAXA ect. |

Plastic material | PP, PC, PS, PE, PU, PVC, ABS, PMMA ect. |

Mould life | 300,000-3,000,000 shots |

Delivery time | 15-60 days |

Payment Terms: | T/T or L/C |

Packaging | Wooden Cases |

Transportation | By Sea or by air |

Export Country | worldwide |

Specification | Depends on customer's requirements. |

OEM order | welcome |

Packaging Detail: | The moulds covered with anticorrosive oil inside and plastic film outside. Final packed in wooden case. Or as per the client's specific requirements. |

Delivery Detail: | 15~60 days. The lead time is subject to the specific mould |

1. Equipment: High Precision CNC. High Speed Miller. Driller. EDM. EDW. Grinding Machine. Engraving Machine. Injection Machine

2. We are manufacturer, so we have competitive price.

3. Diversified rich experienced skilled workers, so we have reliability quality

4. Design: we use the most advanced mould design software Auto CAD, UG...

5. Continuance service and support

6. Providing plastic mould for various parts according to your requirements.

7.Our products possess the advantages of high precision long life and short cycle with reasonable price,prompt delivery.

8..Mould design is subject to customers’ requirements.

9. .Heat treatment of mold can be provided including quencher, nitridation, tempering, etc.

The flow chart of the injection mould

l Receiving the inquire |

l We send the price offer or details to you within 24 hours |

l Customers offer product drawing and some details about the mould |

l Confirming the order (quality, price , material , delivery time , payment terms etc.) |

l According to client’s requirement to prepare the production |

l Clients confirm the details of the mould |

l Surface shaping |

l Drill holes , high speed carve machine ,wire cutting , EDM, etc. |

l Arranging the test mould and sending the samples to customers |

l If clients do not satisfy the samples , please giving us some advices to modify |

l Repair , Polish , Texture |

l We will send the samples to our customers to get their confirmation |

l Making delivery by sea or by air, or following customers’ requirements. |

Taizhou Huangyan Chenhang Mould Factory, established in the year of 2004, is a professional company engaged in mould design, manufacturing & producing. We are specialized in plastic mould, injection mould, commodity mould, kitchenware mould, auto and motorcycle parts mould, SMC moulds,etc.

We had introduced High Speed CNC Centre, Slow-feeding NC wire-cut machine, Deep hole drilling machine,EDM, Wire cutting machine, Grinding machine, Latheing machine etc, all these advanced equipments ensure good quality moulds with short delivery.

1. Q:Are you a manufacturer or trading company.

A:We are mould manufacturer , established since the year of 2004.

2. Q: Where your company or factory ?

A: We are located in Zhejiang, Taizhou , we have our own factory .

3. Q: Can you make design?

A: We'll be glad to make designs for you, both product and mould designs, and for free.

4. Q: What type mould you can make?

A: We can make all kinds of plastic injection mould.

5. Q: What type of files can you accept?

A: We can accept different types of files such as IGES, DXF, DWG, STP, PRT, X_T, PDF.

6. Q: What type of steel do you use?

A:2738, NAK80 , 718H, H13, 2344, S136, P20(H), 4Cr13, S55C,C45#, etc.

Похожие товары

Пластиковые формы для воды

Форма для губной помады ручной работы

Индивидуальная формовочная конструкция от производителя цена кухонная посуда ложка пластиковая литьевая форма

Оптовая продажа Пробойники для резки 100% безопасность лучшее качество от крупного производителя

Латунный быстроразъемный соединитель Hasco

Продвижение от производителя 9-миллиметровые ступенчатые параллельные штифты для совместной работы

ODM-формы для пластикового ведра краски 19 3 галлона упаковка 9 литров барабаны в Китае производитель Taizhou

Новые поступления

Новинки товаров от производителей по оптовым ценам