Машина для производства пластиковых листов uhmwpe/Оборудование экструзии ПП листов

- Категория: >>>

- Поставщик: Qingdao Kechuang Plastic Machinery Co. Ltd.

Сохранить в закладки 60345832118:

Описание и отзывы

Характеристики

uhmwpe sheets plastic sheet making machin/PP board extrusion machinery

Features of Plastic Board/Sheet/Plate Production Line

The production line is suitable for PP, PS, PE, ABS and other plastic materials. If exchanging the machine model head, PVC, PMMA and PC plate materials can also be processed. If adding a drying device, PET sheet material will also be processed.

Main Parameters of Plastic Board/Sheet/Plate Production Line

Model of Extruder | Width of products(mm) | Linear speed(m/min) | Output(kg/h) | |||||||

Calendering type | Casting type | |||||||||

PS | PE | PP | PET | PS | PE | PP | PET | |||

Φ90/33 | 850 | 1.5-15 | 200 | 200 | 150 | 200 | 120 | 150 | 100 | 120 |

Φ90/33 | 1050 | 1.2-12 | 200 | 200 | 150 | 200 | 120 | 150 | 100 | 120 |

Φ120/33 | 1250 | 1.5-15 | 250 | 250 | 200 | 250 | 150 | 180 | 120 | 150 |

Φ120/33 | 1450 | 1.2-12 | 250 | 250 | 200 | 250 | 150 | 180 | 120 | 150 |

Φ120/33 | 1600 | 1.2-12 | 280 | 280 | 220 | 280 | 180 | 200 | 150 | 180 |

Composition of Plastic Board/Sheet/Plate Production Line

| 1. Vacuum auto Loader + Hopper Dryer | 1 set |

| 2. Main single screw extruder | 1 set |

| 3. Hydraulic network auto changing system | 1 set |

| 4. Mould/Die head | 1 set |

| 5. Three-roller Calender | 1 set |

| 6. Temperature controller of three rollers | 1 set |

| 7. Cooling frame with side cutting unit | 1 set |

| 8. Haul off machine | 1 set |

| 9. Cutting machine | 1 set |

| 10. Stacker or Winding machine | 1 set |

Production Process of Plastic Board/Sheet/Plate Production Line

Photos of Plastic Board/Sheet/Plate Production Line

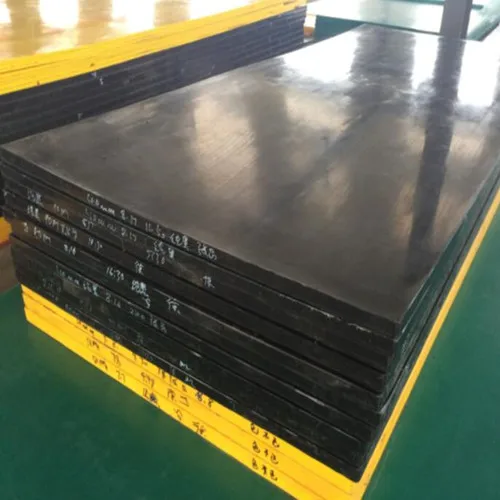

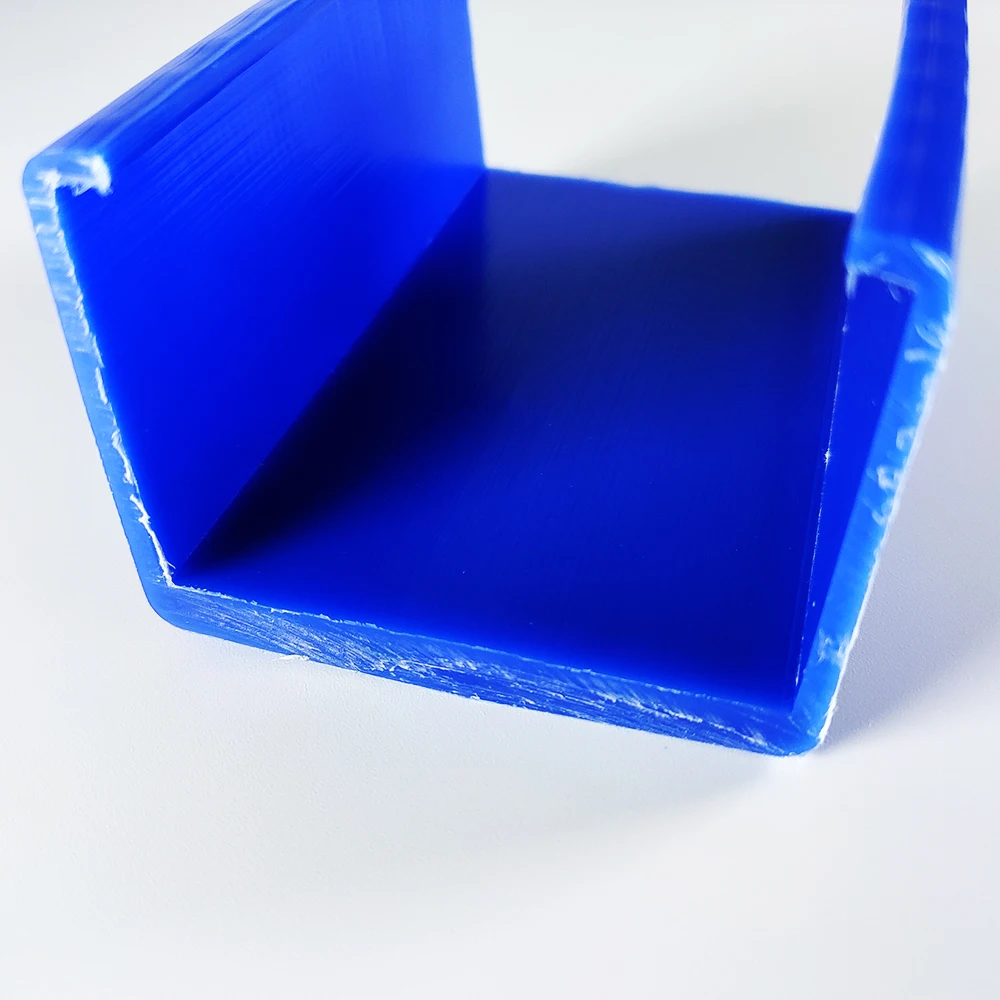

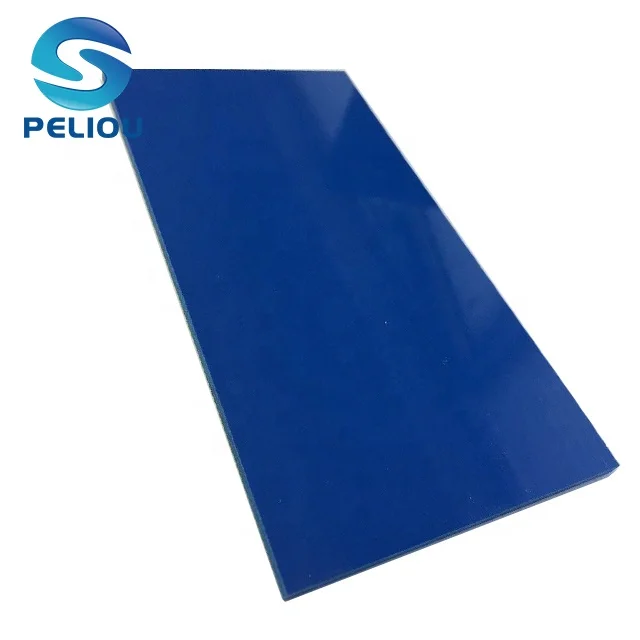

Final Product Photos of Plastic Board/Sheet/Plate Production Line

1.Our company will provide relevant information on various technology and business consulted by customers. If clients want to visit our company, we will offer all they need for convenience.

2.After cooperation, our company designs groundsill installation chart for water, electricity and gas of equipment basing on real condition and customers’ requirements and provides detail order list and matching manufacturer for reference for customer.

3.After equipment arrival, our company will arrange professional technicists to buyer's factory for installing machines and train workers till customers can operate independently and manufactures eligible product.

4.KC machinery will be responsible for changing broken parts within warranty and then provide parts only with pure cost.

1.We are professional China Leading Plastic Machine Manufacturer.

2.Inspected by the Inspection Institution of SGS Certification.

3.100% QC inspection Before Shipment.

4.Best Quality & Best Service with Competitive price.

Sincerely look forward to receving your inquiry and cooperation in long-term!

Похожие товары

Студийный чехол Keyson с подсветкой и динамиком и зарядным устройством USB

Высококачественная оригинальная новая система Boses S1 Pro PA с подставкой для динамика и проигрываемым чехлом-Bo Nue Black

Лидер продаж uhmwpe по низкой цене

Производитель, ударопрочный портативный защитный чехол для хранения, жесткий переносной инструмент, динамик Jbl boombox2, большой чехол из ЭВА с молнией

Цепная направляющая для пищевой промышленности, пластиковая деталь для станка из полиэтилена высокой плотности

Нетоксичный пищевой uhmwpe лист 3/4 дюйма Прозрачный uhmwpe пластиковый лист uhmwpe

Импортный материал, медицинский класс uhmwpe пластиковый лист

Новые поступления

Новинки товаров от производителей по оптовым ценам