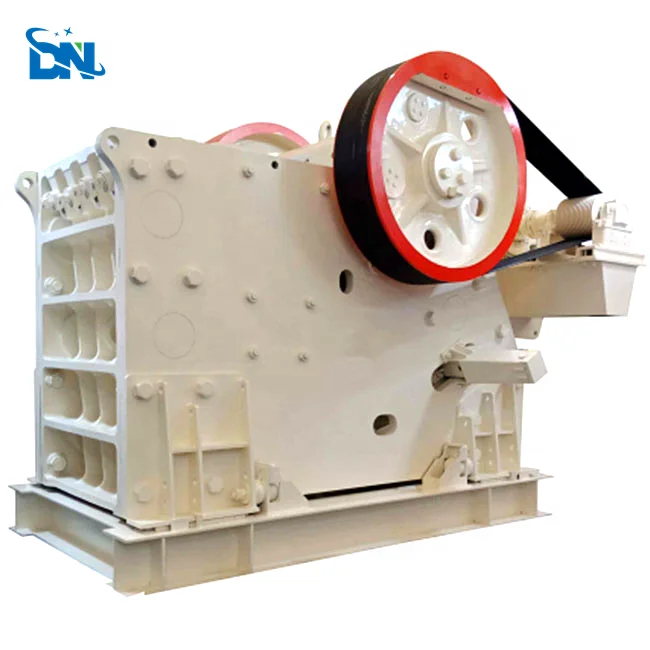

Машина для переработки металла металлическая дробилка гидравлическая молотковая

- Категория: Дробилка >>>

- Поставщик: Gongyi Derui Machinery Co. Ltd.

Сохранить в закладки 60397961790:

Описание и отзывы

Характеристики

Scrap metal recycling machine hydraulic metal crusher

Scrap Metal Crusher Machine Application:

Metal crusher is more popular in the field of metal recycling mill metal processing equipment, the machine can crush materials include: Sprite cans, Lulu cans, Red Bull cans, cans, can crush beverage cans, paint cans can also be crushed, oil tank, as long as the metal can be crushed, pulverized material is very easy to carry out transport, easy to feed steel, also reduces the number of feed lot.

In the process of crushing force applied to the solid with pressure roll, cut, impact, grinding four. Rolled mainly used in rough, broken, suitable for hard material and bulk material crushing;cut is mainly used in crushing, grinding toughness suitable materials; impact is mainly used in crushing, fine grinding,fine grinding, fitness crushing brittle materials; grinding mainly in fine grinding, fine grinding, suitable for small and fine particles of pulverized. The actual grinding process is often several forces acting simultaneously.

Main Features

1) Unique design, fully enclosed soundproof, can effectively absorb noise and vibration generated by crushing, pulverization and low noise (approximately 85db), in order to achieve low noise and environmental protection purposes.

2) Unique Ling but water system, the heat generated by the machine to the machine, which can effectively avoid the crushed material caking.

3) The body of the whole machine steel, compact, durable, long-term use does not affect the mechanical properties of the material due to crushing.

4) Heavy load bearing and seal means, ensure that the processing material from oil contamination.

5) Motor equipped with overload protection device, and the power supply interlock protection system; cleaning tool with protection devices to ensure the maintenance of security personnel.

Working Principle

The core principle is to use the hammer to hit raw materials. Through the space between the lining and the hammer head, the broken material will be torn into a suitable fragments . And the suitable fragments can be discharged through the mesh. At the same time, the size of the mesh can be selected according to the size of the broken material.

Machine Maintenance

1.The laying-off should be kept evenly to ensure the crushing quality and normal production, and the motor overload is strictly forbidden to ensure the normal operation of the machine.

2.In addition to regular attention to check all parts tighten and loose, also should pay attention to check the wear condition of wear parts, if wear seriously should be replaced in time, lest damage main parts. And take necessary precautions against fire.

Because of the high speed, except the installation is correct and strong, and should maintain good lubrication, in order to keep the machine operate normal

Metal Crusher Technical Parameter:

Model | Max feeding size | Dimension(L*H*W)m | Output | Power(kw) | Coverage(m²) |

600 | 600*350mm | 2.0*2.2*1.6 | 500kg/h | 18.5-22 | 28 |

800 | 800*350mm | 2.2*2.4*1.8 | 1000kg/h | 37 | 28 |

1000 | 1.0*0.65m | 2.8*2.6*2.2 | 1.2-1.5t/h | 55 | 40 |

1000 | 1.0*0.65m | 3.2*2.8*2.0 | 2-2.5t/h | 75 | 45 |

1300 | 1.3*0.8m | 3.5*3.2*2.1 | 2.5-4t/h | 90-110 | 45 |

1600 | 1.6*0.8m | 3.8*3.4*2.4 | 5-6t/h | 110-132 | 50 |

1800 | 1.8*0.8m | 4.0*3.6*2.6 | 6-8t/h | 132-160 | 55 |

2000 | 2.0*0.8m | 4.2*3.6*2.8 | 8-10t/h | 200-220 | 80 |

Why Choose to Crush the Metals???

1. Convenient particles transport, which can effectively reduce transportation costs, improve transport efficiency;

2.Broken material sales price is much higher than the price of untreated waste;

3.Metal particles greatly facilitate the use and re-processing

1. Pre-sale support

1) We offer the best solution according to client’s requirement in time.

2) We accept and respect client’s creative idea. We will try our best to integrate client’s idea into the machine and take our years of experience into consideration.

3) We accept client’s sample materials sending for test and take videos.

4) We could offer our technical design before the purchase order.

2. After-sale service

1) Our skilled technicians are available for on-site installation, commissioning & training on request.

2) Dimensional drawings together with service requirements will be provided prior to delivery of the equipment.

3) An adequate inventory of spare parts and efficient service personnel are available for emergency case. Customers should keep the critical spare parts, like crusher knife and screen, so that we could get to know the spare parts you need.

4) Our guarantee period is 24 months. Within the guarantee period the broken parts (excluding quick-wear parts) can be exchanged with our new parts if it is not caused by human factors. And technicians are available for solving big problems overseas. Beyond the guarantee period the broken parts dispatched are charged at cost price.

5) Other after-sale service terms are negotiable.

Our Company Philosophy

Best Quality for Market

Perfect Service for Clients

Scientific Management for Benefits

Good Credit for Development

Gongyi Derui Machinery Co., LTD entered the mechanical industry from the beginning of the 1980’s, earlier than most factories. With the company philosophy these years, our products are sold to many customers from home and abroad, popular in India, Russia, Kazakhstan, Africa, South America, Mid-East, Southeast Asia, and almost 30 countries and areas. And it is our honor to make a contribution of to the development of these countries.

Growth is only a process, and the brilliance is the new beginning. In order to respond positively to the good policy of The Belt and Road, we will, as always, provide higher and higher quality products and service, to win more and more acclamation and respect for Chinese national industry. Review ourselves with serious attitude, and win the trust with excellent quality. We sincerely hope to take win-win cooperation with entrepreneurs and companies all over the world, to develop the market together.

Q:What is the MOQ?

R:MOQ is 1 set,we allow OEM and sample order,but the cost are paid by your side.

Q: Where is your factory located? How can I visit there?

R: Our factory is located in Zhengzhou City, Henan Province, China.Contact us ahead before you go visit,then we can fully arrange the schedule and meet you.Welcome to visit us!

Q: What is the warranty time of your products?

R: The warranty time is 12 months from the date of the commissioning.After the warranty, any questions and needs,please contact us.

Q: How does your factory do regarding quality control?

R: All products have to pass strict inspection before they ship out.And we have gained ISO9001:2008 authentication.If you need other certificate and quality control,please contact us.

Похожие товары

Мини-щековая дробилка используемая в лаборатории с размером входа 120

Breaking станция промышленный мини рок щековая дробилка для камня делая машину

Китайский производитель, мобильная дробильная установка гусеничного типа, передвижная совокупная каменная дробильная установка 150Tph

Мини-Мобильная камнедробилка, дизельный двигатель, небольшая щековая дробилка pe150x250 для горных работ, прайс-лист

Ударная мельница/булавочная мельница

Продажа с завода, щековая дробилка для камня, мобильная дизельная щековая дробилка с вибрационным экраном

Крупногабаритная Тяжелая дробильная машина, линия по производству камня, большая емкость, щековая дробилка, цена, щековая дробилка

Новые поступления

Новинки товаров от производителей по оптовым ценам