Новый OEM Твердосплавный бор для совместной области шлифовательная резка B0416 B 13

- Категория: >>>

- Поставщик: Suzhou Syndent Tools Co. Ltd.

Сохранить в закладки 60406362374:

Описание и отзывы

Характеристики

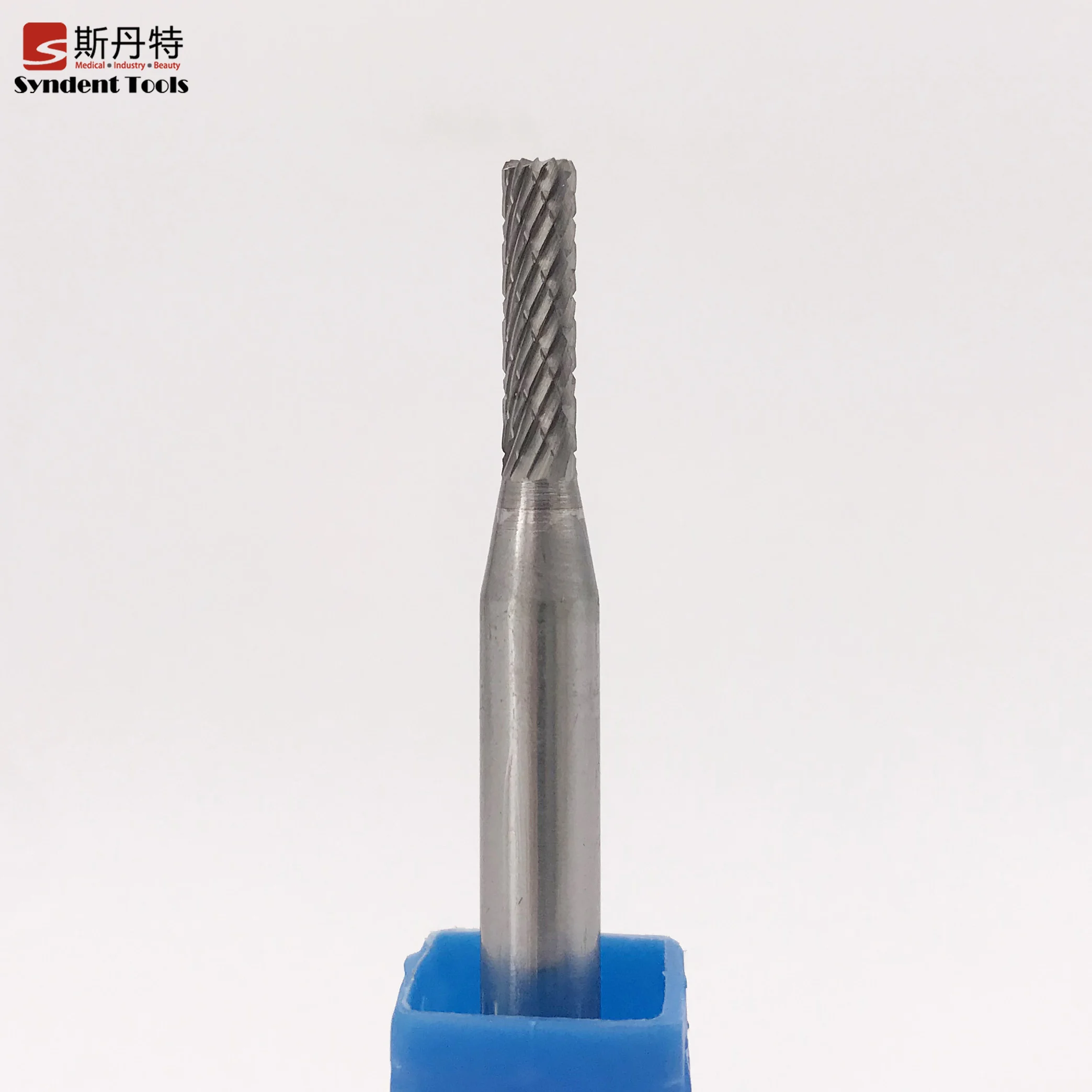

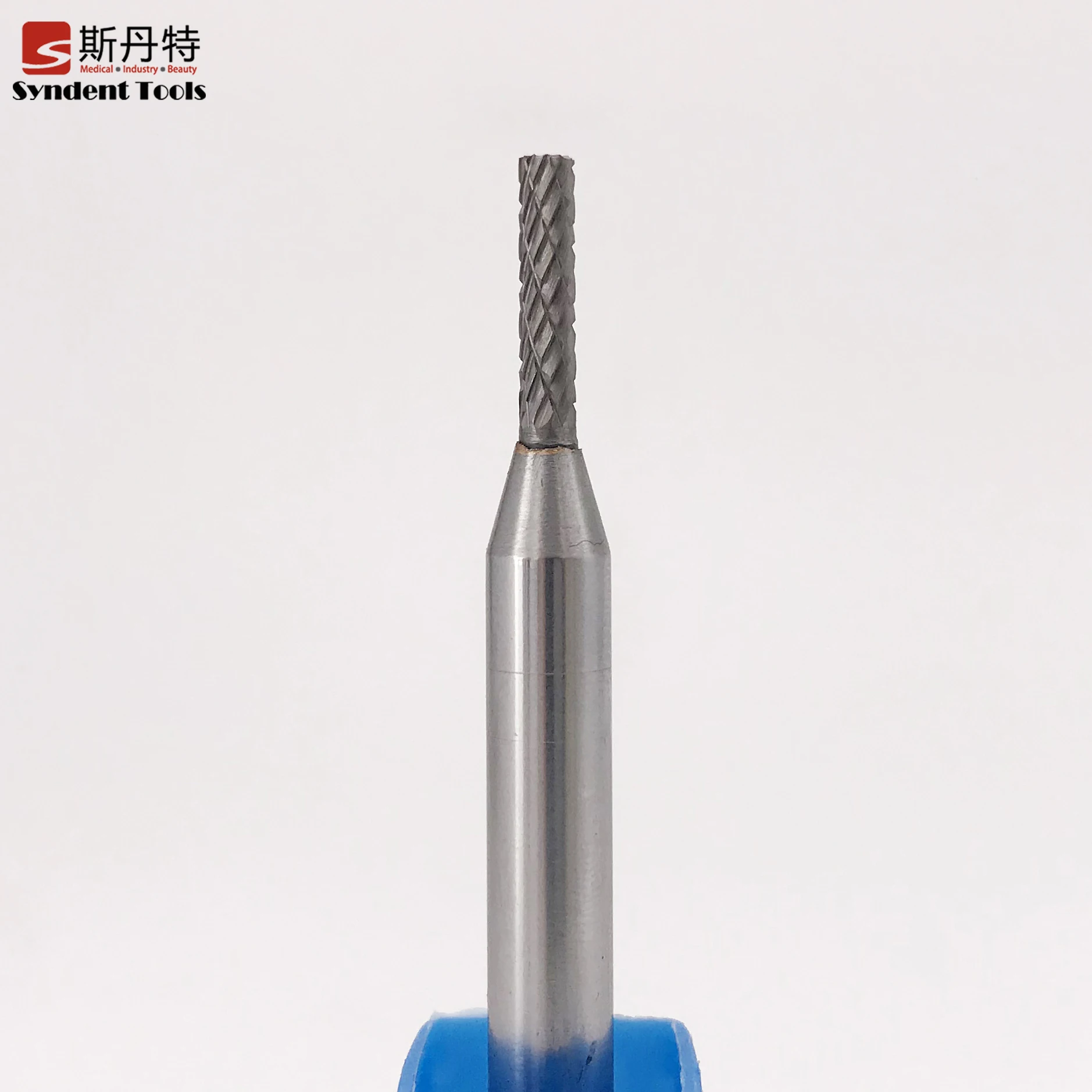

New OEM carbide bur for joint area die grinder B0416 B-13

Description of 12mm carbide burr for die grinder

- Metric size tungsten carbide burs are available upon customer’s request.

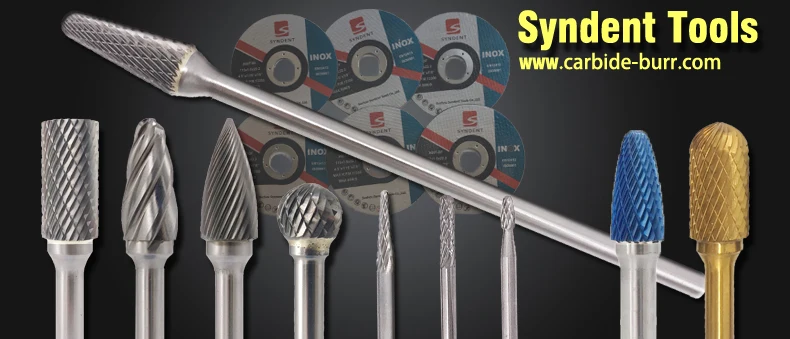

- SYNDENT tungsten carbide burrs produced with high quality types of carbide and modern CNC grinding machines.

- Our rotary burrs are brazed by the advanced welding equipment automatically. Silver brazing materials are imported from USA.

- Carbide burrs manufactured to your drawings to meet your demands of particular stock removal.

- We can make chemical and geometry analysis for your carbide burs material and make grinding test in our professional laboratory center.

- SYNDENT tungsten cutter can be coated with TiN, TiCN, TiALN and LTE.

- OEM of many famous huge companies in the world. for our carbide cutter.

Specification of 12mm carbide burr for die grinder

| Item name | Cylinder Shape Carbide Burs (With End Cut) |

| Model | SB-13 |

| Shape | Cylinder with End Cut |

| Inch size of flute | 5/32---5/8 |

| Metric size of flute | 4---16 |

| Main Material | Tungsten carbide |

| Grade | K30 or K25 or K20 |

| Brazing type | Silver brazing |

| Cut style | D/C,S/C,A/C,Diamond |

Application of 12mm carbide burr for die grinder

- Please browse www.carbide-burr.com And find the category Selection Guide and find sub category Industrial carbide burrs.

- The best results are based on selecting the recommended cut and speed. Please refer to the cutting speeds and various cuts in the above area.

- Please kindly let us know when you need to grind hardened metal like stainless steel, alloy steel.

CARBIDE BURR SELECTION AND USE:

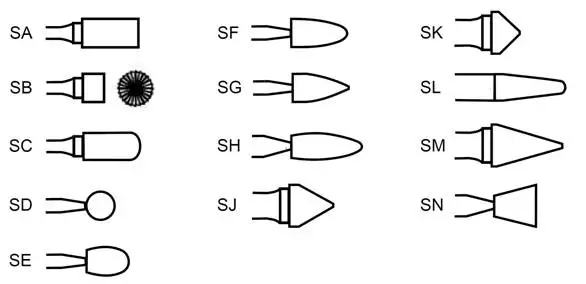

The first step in selecting the proper burr is to pick the best shape and cut style.

- Selection of shape and diameter should be based on the work piece, and the operation to be performed.

- Burs have 13 basic shapes:

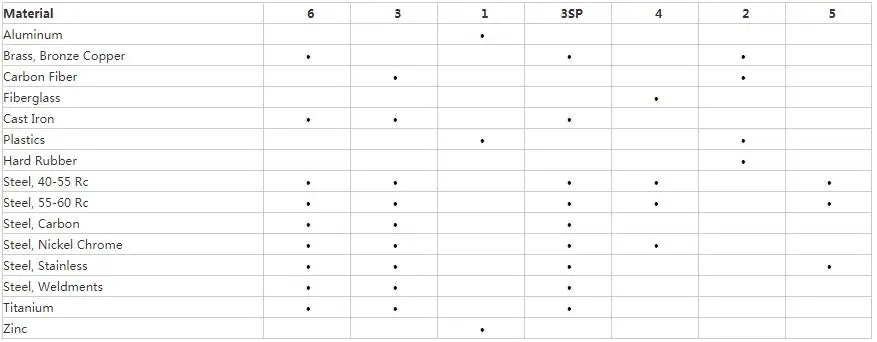

Burs come in 7 kinds of flute style as following.

6 - Double Cut: Very efficient stock removal. Creates a small chip. Good finish. Excellent operator control.

3 - Single Cut: General purpose fluting. Produces long chips.

1 - Nonferrous: For nonferrous materials. Aggressive stock removal.

3SP - SP Chip Breaker: Provides breakdown in chips. Better control.

4 - Diamond Cut: For heat treated and tough alloy steels where control is important. Creates a powder-like chip. Excellent finish.

2 - Coarse Cut: Provides large flute area for softer ferrous materials. Fast stock removal.

5 -Fine Cut: For general use on hard materials requiring a fine finish.

Selection of cut would be based on the material, and finish required.

The second step in selecting the right tungsten carbide grade.

We have metric size and fractional size for industrial carbide burrs. Meanwhile, we have 3 kinds of different carbide grades named K30, K25, K20 for carbide burrs.

| Grade | Cobalt | HRA | HRC | Density (ISO 3369) | Transverse rupture strength (ISO 3327) |

|---|---|---|---|---|---|

| K30 | 8% | 89.3-89.5 | 74.3-74.6 | 14.8 | 2000 |

| K25 | 7% | 89.5-90.5 | 74.6-77 | 14.9 | 2650 |

| K20 | 6% | 90.1-91.5 | 76.2-78.4 | 14.7- 15 | 1800 |

The third step in selecting the right rotary speed for SYNDENT carbide burr.

These are general speed recommendations that may need to be adjusted for special application

12mm carbide burr for die grinder

Похожие товары

Воздушные шары из фольги mylar с надписью «гелиевые буквы», 16, 32, 40 дюймов

Инструмент трансформатор наружный эпоксидный литой смолы масляный Тип комбинированный трансформатор

LB6-66 66kV 69KV 72KV масляный однофазный уличный силовой трансформатор

Vividstorm S Pro 100 дюймовый моторизованный проекционный экран с защитой от света, отклоняющий ALR экран 16:9 UST проекционный экран

Лидер продаж, трансформатор маслового типа из меди onan/onaf 34,5 кв 5 МВА

JDJ2-35 однофазный, заполненное жидкостью трансформатор масляные типа трансформатор напряжения

16 видов цветов Палитра теней для век, матовые тени для век, база, частная этикетка, хорошее качество, Новые поступления, тени для век, порошок, логотип клиента

Новые поступления

Новинки товаров от производителей по оптовым ценам