Ультратонкое дробильное оборудование

- Категория: >>>

- Поставщик: Luoyang Zhongyuan Mining Machine Manufacture Co. Ltd.

Сохранить в закладки 60411482411:

Описание и отзывы

Характеристики

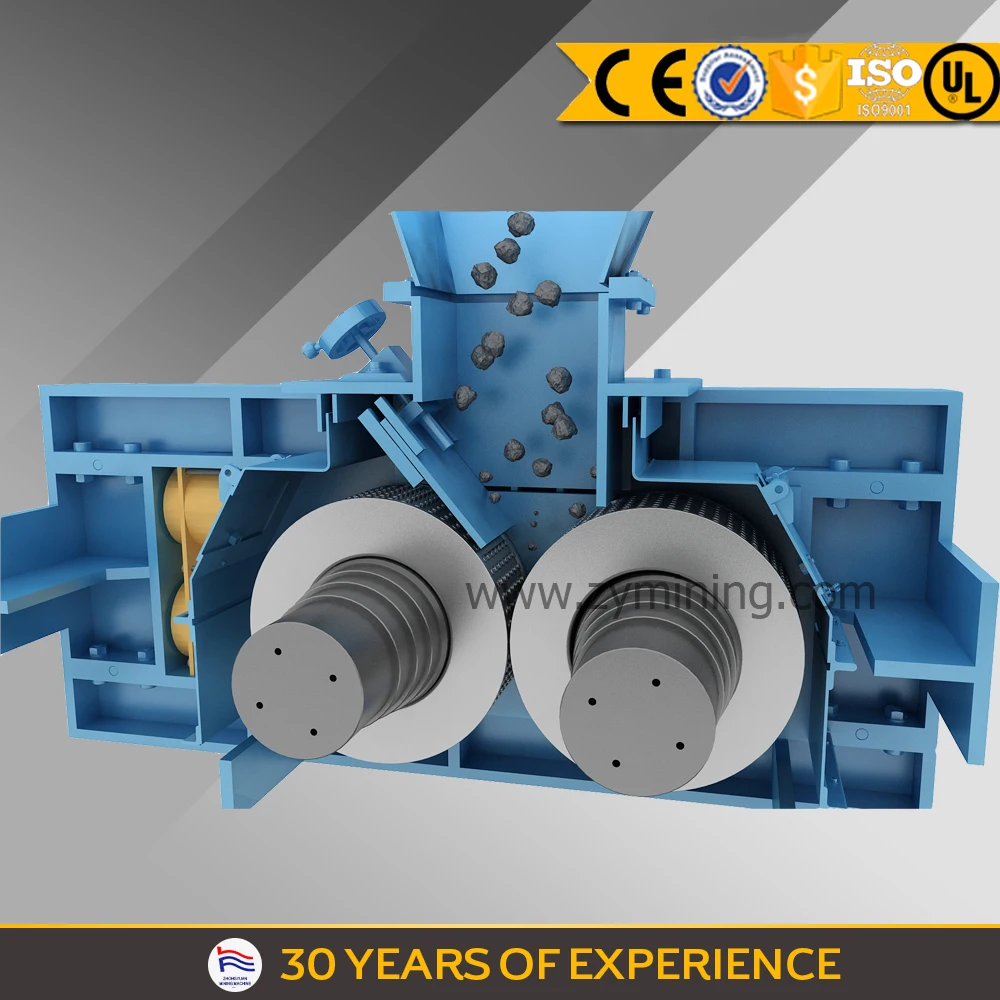

Ultra-fine Crushing Equipment

City, covering 30000 m2. Since established in 1986, it is specialized in developing and

manufacturing briquetting & compacting system, crushers, cement equipments, coal

machinery, conveying equipments, mixing equipments and other complete plant which

can be widely used in metallurgy, mine, building materials, chemical, coal, power and

urban garbage disposal industries. Our products have been exported to Southeast Asia,

Europe, Africa, Asia and other areas. The company has passed the ISO9001:2000. GY

series briquette machine has CE certificate. Equipments also could be tailored according to customer’s requirements.

Model | Roller dia.(mm) | Roller width (mm) |

Power (kw) |

Feeding size(mm) |

Finished size (mm) |

Throughput (t/h) |

Weight (t) | ||

Metal ore (mm) |

Powdered Iron(cm2/g) | Metal ore (mm) |

Powdered Iron(cm2/g) | ||||||

GM600-200 | 600 | 200 | 2X75 | ≤25 | 1100-1300 | ≤3 | 1400-1600 | 16-24 | 14 |

GM800-300 | 800 | 300 | 2X110 | ≤30 | 1100-1300 | ≤3 | 1400-1600 | 39-58 | 24 |

GM1000-300 | 1000 | 300 | 2X160 | ≤35 | 1100-1300 | ≤3 | 1400-1700 | 61-91 | 32 |

GM1000-400 | 1000 | 400 | 2X200 | ≤35 | 1100-1300 | ≤3 | 1400-1700 | 80-120 | 36 |

GM1000-500 | 1000 | 500 | 2X280 | ≤35 | 1100-1300 | ≤3 | 1400-1700 | 100-150 | 40 |

GM1200-500 | 1200 | 500 | 2X315 | ≤40 | 1100-1300 | ≤3 | 1600-1800 | 130-190 | 56 |

GM1200-630 | 1200 | 630 | 2X400 | ≤40 | 1100-1300 | ≤3 | 1600-1800 | 160-240 | 65 |

GM1200-800 | 1200 | 800 | 2X500 | ≤40 | 1100-1300 | ≤3 | 1600-1800 | 200-310 | 79 |

GM1400-800 | 1400 | 800 | 2X560 | ≤50 | 1100-1300 | ≤3 | 1600-1800 | 260-390 | 110 |

GM1400-1100 | 1400 | 1100 | 2X800 | ≤50 | 1100-1300 | ≤3 | 1600-1800 | 360-540 | 133 |

GM1700-1100 | 1700 | 1100 | 2X1000 | ≤60 | 1100-1300 | ≤3 | 1600-1800 | 530-800 | 179 |

GM1700-1400 | 1700 | 1400 | 2X1250 | ≤60 | 1100-1300 | ≤3 | 1600-1800 | 670-1000 | 208 |

There has 50 sets of machinery and

equipments to manufacture standard or

customer tailored mining equipments.

The maximum lifting capacity of the

mechanical processing reaches 40T,

and the maximum lifting capacity of the

assembling reach 65T. The company

has a complete testing capacity and a

highly-efficient and complete product

quality inspection tracking system.

customer to

visit the

factory and

talks

Q1 Whychoose us ?

We have a professional rich experiences stuffs;

We have the largest factories and production capacity since 1986;

The ZHONGYUAN euqipment, worthy of your trust!

Q2Does the equipment have any special?

1.The application of high pressure grinding roll can improve the productivity of the powder grinding system by 20%-30%.

2.Power consumption of grinding system can decrease by 25-50% compared with the traditional grinding method.

3.The machine is equipped with sealing cap for rollers which can control the harmful dust spread to create a better production environment.

4.The machine has following advantages such as compact structure, less space-occupation, high reliability. Its operation efficiency can be up to approx.95%.

Q3Does it's working performance high?

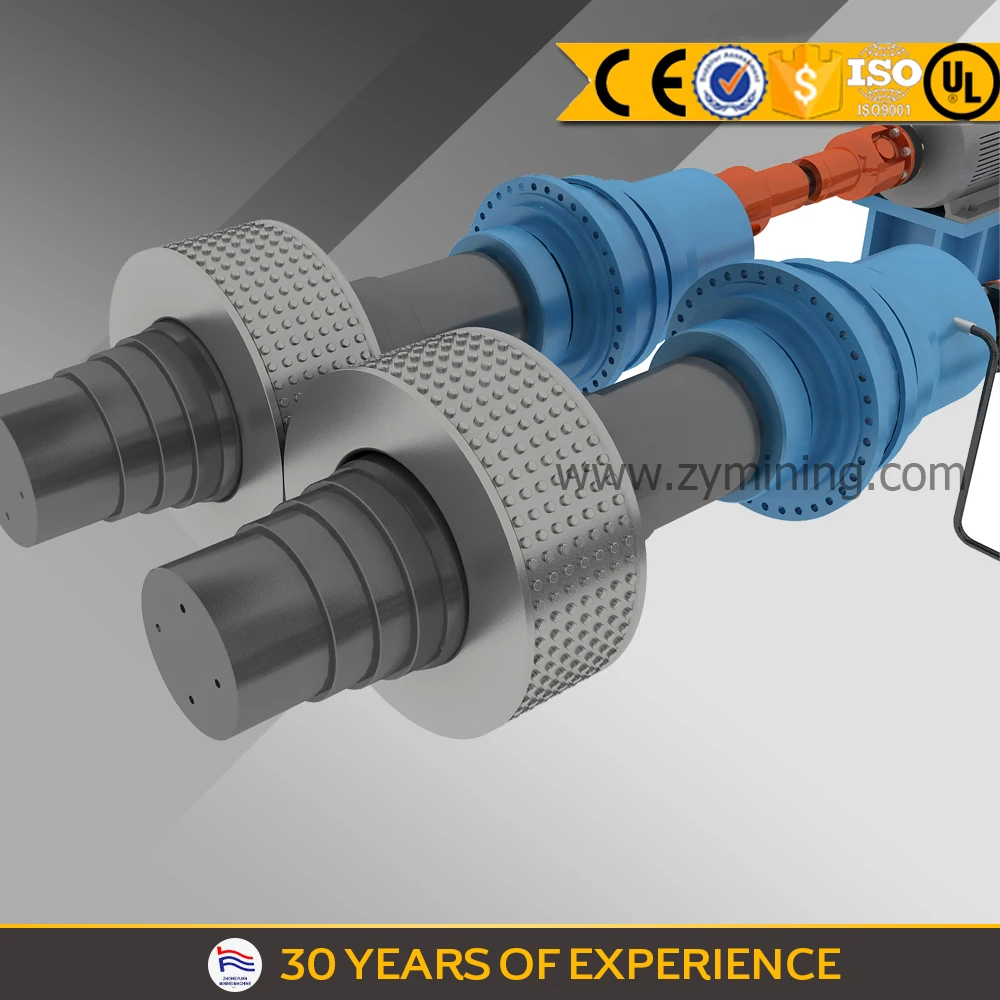

1.Rolls adopts high quality alloy (tungsten carbide) with an antogenous wear protection layer to prolong service life;

2.There is the rapid roll chang-our design which is very easy for customer.

3.Sturdy struction could realize interpartical breakage, micro-cracking.

4. Comparing to crushers and mill, HPGR has advantages such as energy efficiency for the downstram comminution process.

Похожие товары

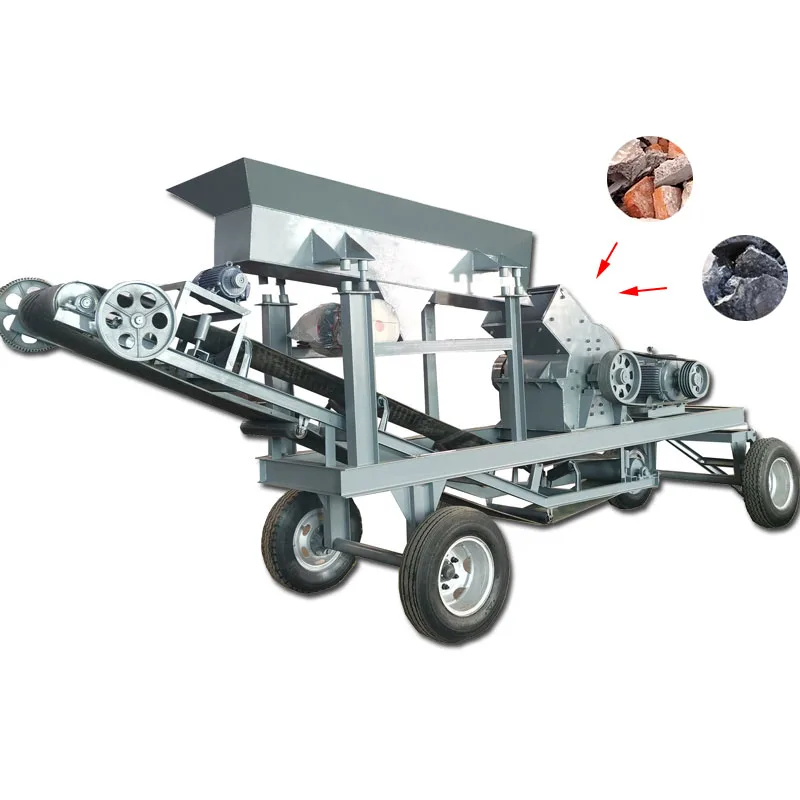

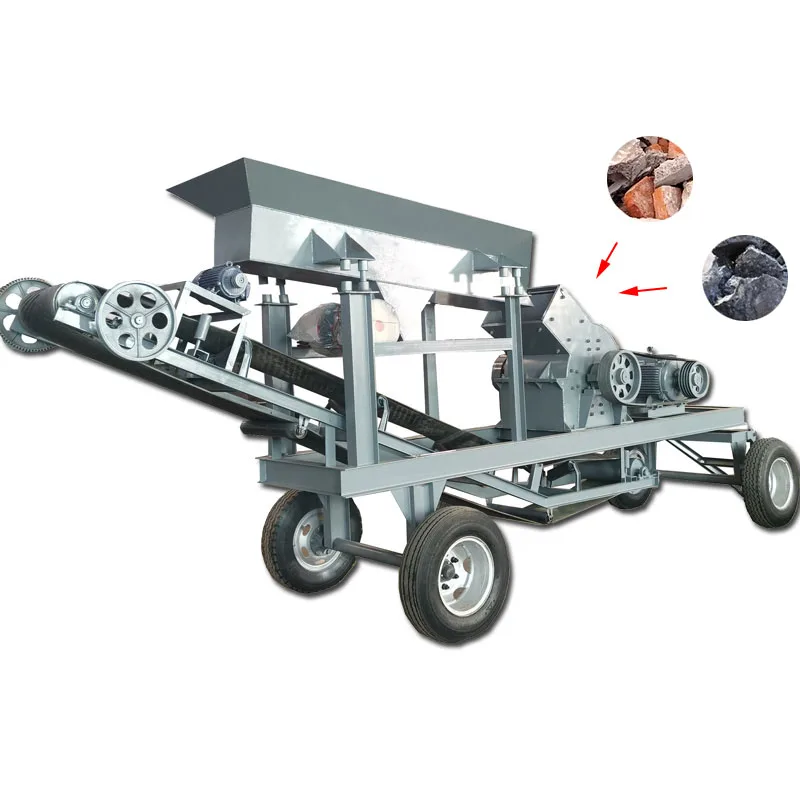

Молотковая дробилка для небольших камней, мобильная машина, камнедробилка, вибрационный экран для дробилки

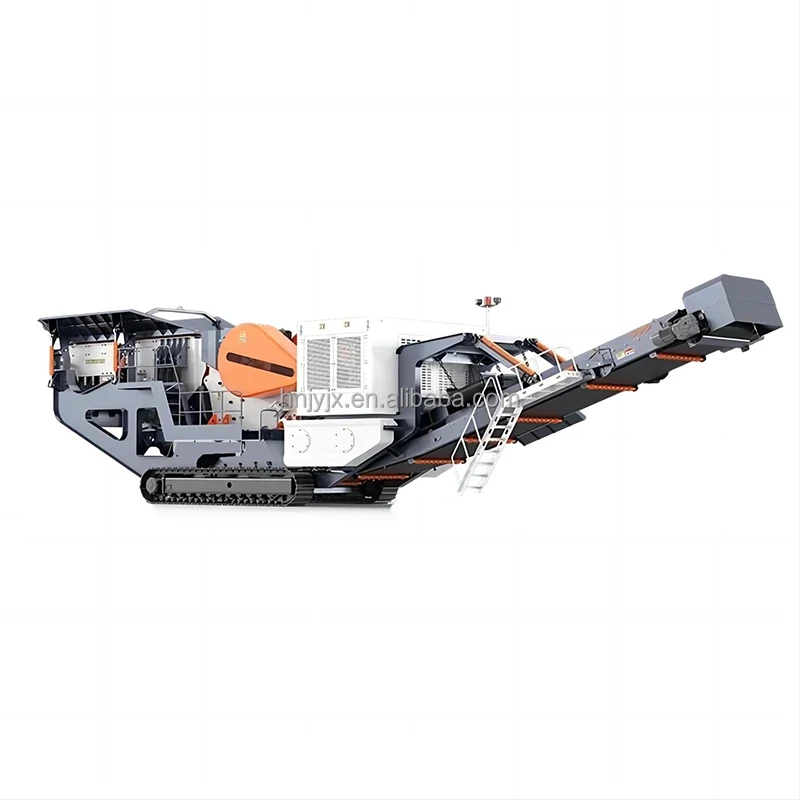

Большая емкость, передвижная гусеничная дробилка для дробления известняка, кварцевого гранитного базальтового диабаза для производства камня

Передвижная молотковая дробилка бентонитовая дробилка производственная линия дробления горных пород с вибрационным экраном

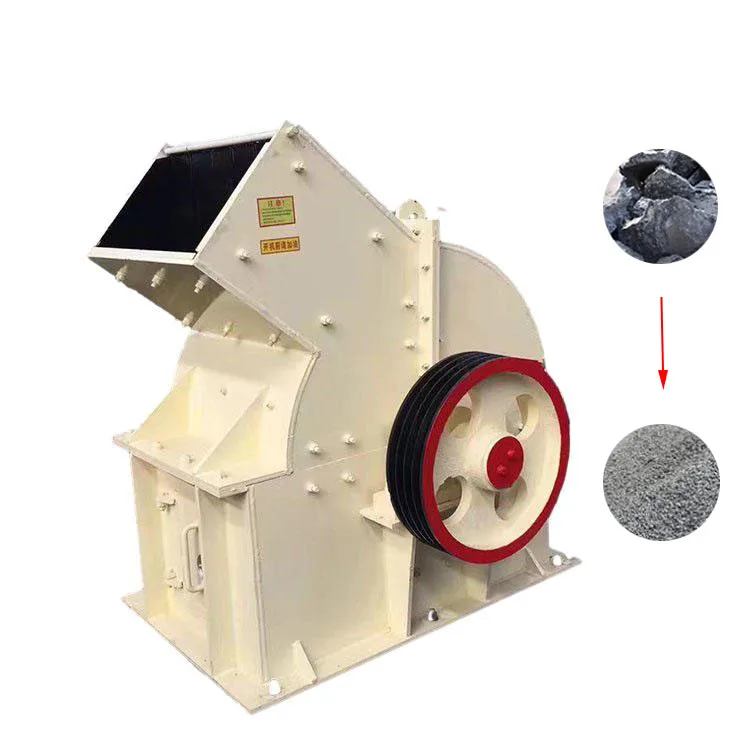

Молотковая дробилка

Портативный мобильный камень молотковая дробилка известняк дробилка Мраморный Песок дробилка прайс-лист

Портативная дробилка для стеклянных бутылок

Небольшая Мобильная молотковая дробилка, гравийная линия по производству известняка, дробление и песок, оборудование

Новые поступления

Новинки товаров от производителей по оптовым ценам