Автоматическая машина для высечки головы одноразовая производства

- Категория: Leather Production Machinery >>>

- Поставщик: Jiangsu Atong Machinery Manufacturing Co. Ltd.

Сохранить в закладки 60419535854:

Описание и отзывы

Характеристики

FACTORY DIRECT SALE

YOU CAN GET THE BEST PRICE, GOOD QUANLITY, AND FAST DELIVERY.

How to choose the most suitable disposable slippers making machine traveling head cutting machine for your business?

1)material: nonmetal

2)Cutting area depends on your material size.

3)Feeding system depends on your material style ( rolls or sheets).

4)The force depends on the perimeter of the die blade.

Welcome to contact us for select the right model.

Working video: www.cuttingmachinechina.com

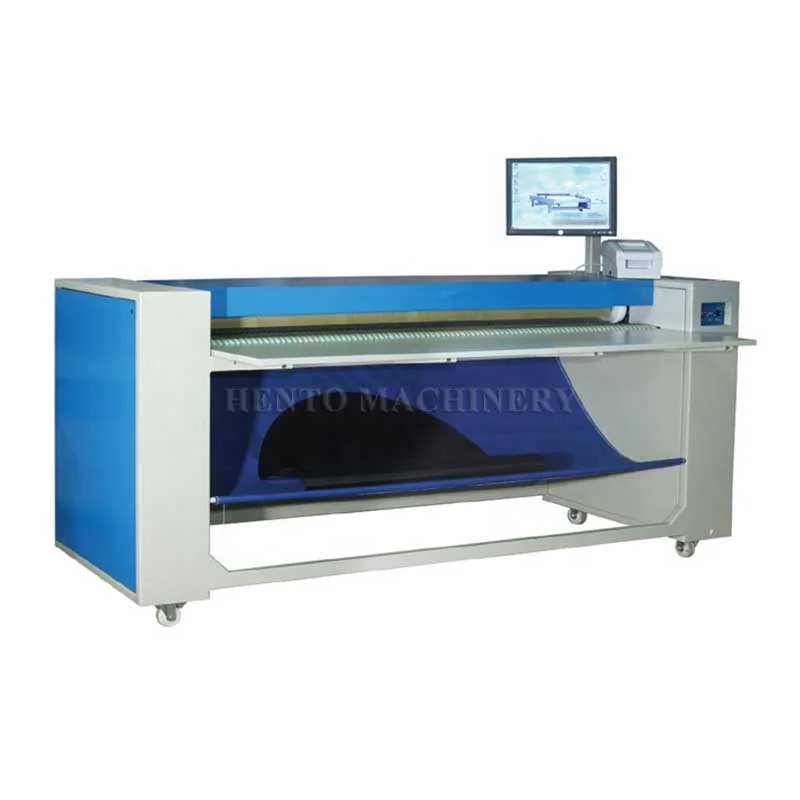

automatic travelling head cutting machine disposable slippers making machine

PRODUCT DETAILS

Dies for cutting machine

our die cutting machine need to work with dies

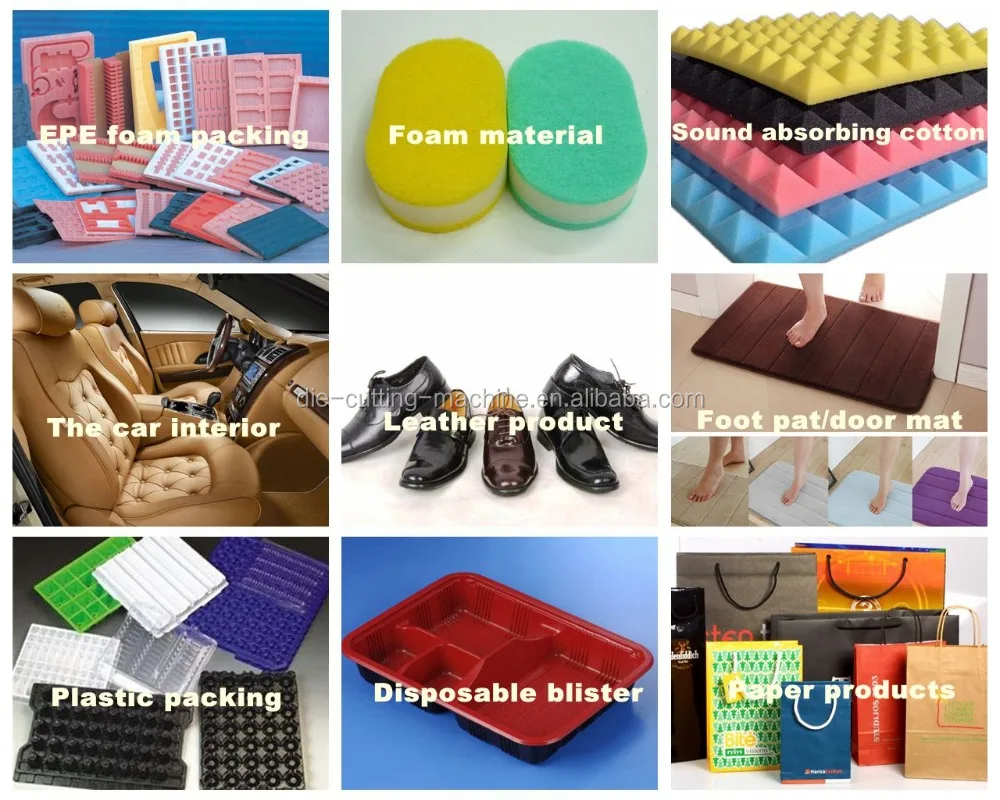

automatic traveling head die cutting machine disposable slippers making machine WIDLY USED IN DIFFERENT MATERIALS

THE APPLICATION

This kind of automatic traveling head die cutting machine disposable slippers making machine Mainly used for die cutting leather and leather products,plastic,rubber,sponge,foam,EVA,PVC,

cardboard, paper products,fabric,home textiles,packaging materials,non woven,carpet,car

cushion,felt,synthetic materials, and other nonmetallic materials in various industries;

Extremely suitable for cutting multiple layers of material at one time. as long as the match to be on the molding box knife, can get various shapes of products, such as soles, shoes, handbags, gloves, toys, clothing, blister, plastic and craft products.

automatic high speed traveling head die cutting machine disposable slippers making machine

Technical specification

Model | JSAT2-400/500 |

Max cutting force | 400/500KN |

Cutting speed | 0.18m/s |

Travel adjustment range | 0-120mm |

Range between the working table | 30-175mm |

Feeding speed | 20-90mm/s |

Size of the upper pressing board | D500mm |

Area of working table | 1600*500mm |

Motor power | 5.5kw |

Overall dimension | According to machine configuration |

use and characteristics

This kind of traveling head cutting machine disposable slippers making machine is suitable for continuously cutting large batch of regular(or the same specification) nonmetal rolled materials by forming cutter.It di especially suitable for such industries as sports articles(balls), sand paper, medicine and etc.

1. The mechanism of double oil cylinder, gantry type guiding and precise four-column automatic balancing connection rod can guarantee the same cutting depth of each cutting position.

2. The precise lead screw driving unit is adopted for accurate movement and positioning and stable operation.

3. The rubber roller pneumatic material pressing or manual material pressing is adopted.The computer can automatically control the transverse movement distance of cutting head and the feeding distance of pressing roller.

4. The machine has special cutting modes such as automatic stagger and stagger blade reducing, which can reduce consumption and save raw materials.

Похожие товары

Осциллирующий режущий станок 1600*2500 мм с автоматической подачей для резки ткани и кожи простой в эксплуатации

Высокое качество измерительная лента кожа/кожаная рулетка/измерительная

Горячая Распродажа измерительная машина для области кожи

Производитель Женская машина для изготовления кожаных штанов тайская мужские кожаные ботинки резки Автоматическая производственная

Автоматический аппарат для ламинирования искусственной кожи PU PVC 850

Бывшая в употреблении итальянская машина для производства обуви Atom VS922 20T гидравлический поворотный кронштейн пресс штамповочная

Нож Nippy NP1240 для разделения

Новые поступления

Новинки товаров от производителей по оптовым ценам