Сборная машина для изготовления бетонных плит с полым сердечником крыши и пола

- Категория: >>>

- Поставщик: Ningjin Shuangli Building Materials Equipment Co. Ltd.

Сохранить в закладки 60423671043:

Описание и отзывы

Характеристики

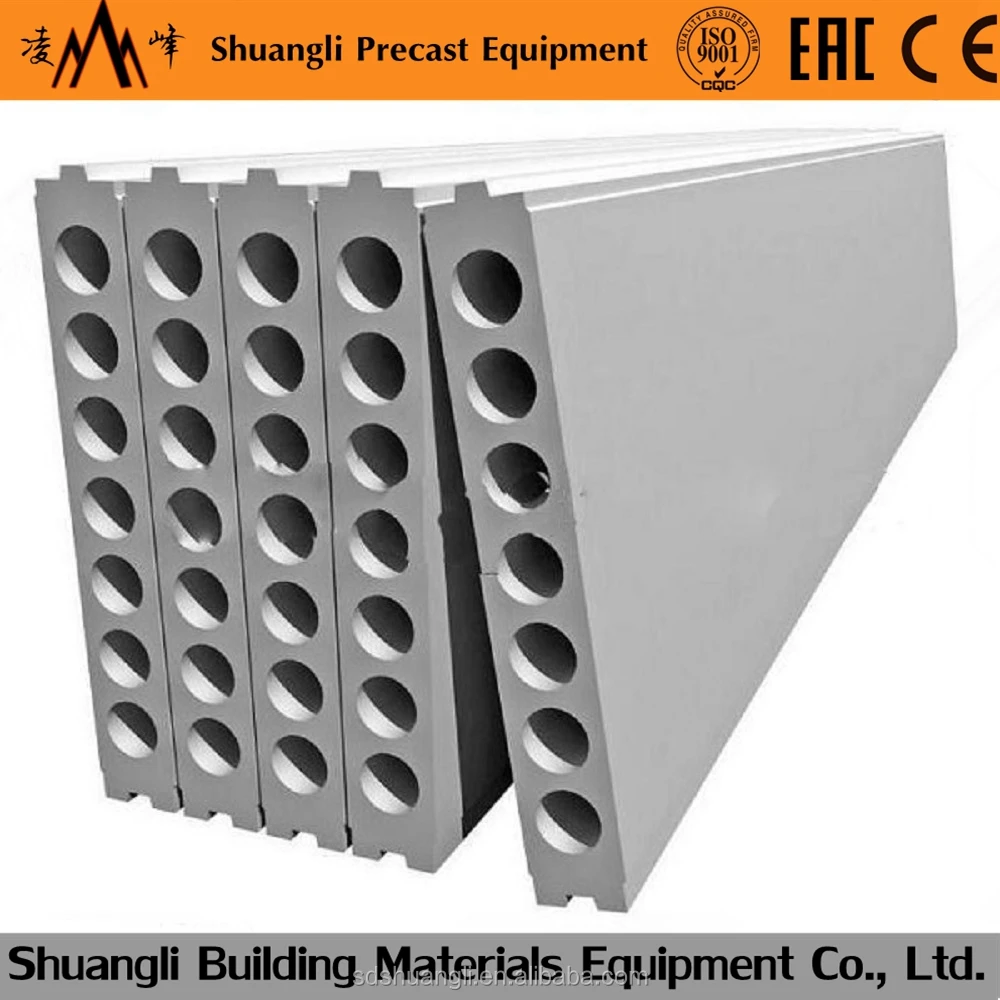

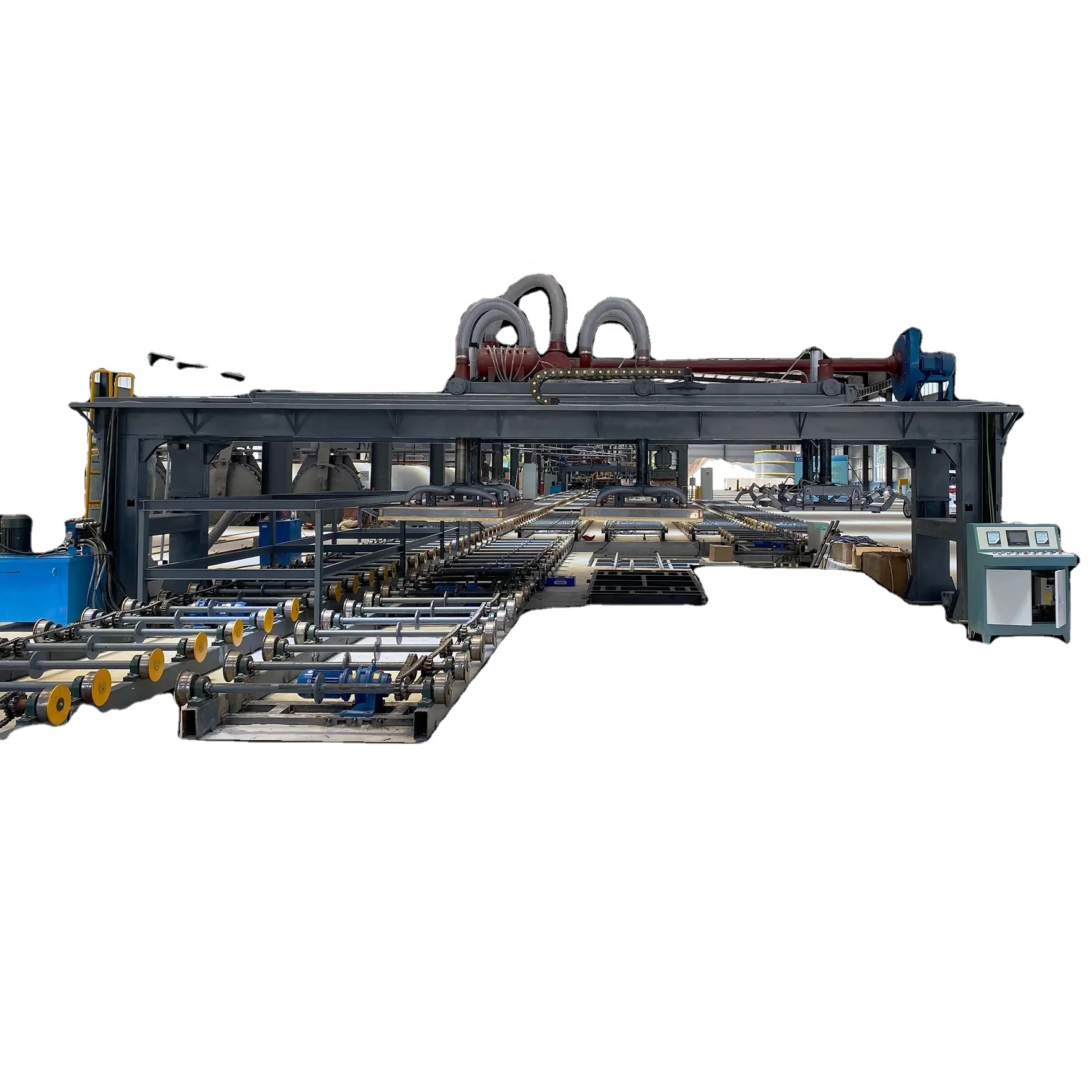

Precast Hollow Core Concrete Slab Making Machine For Roof and Floor

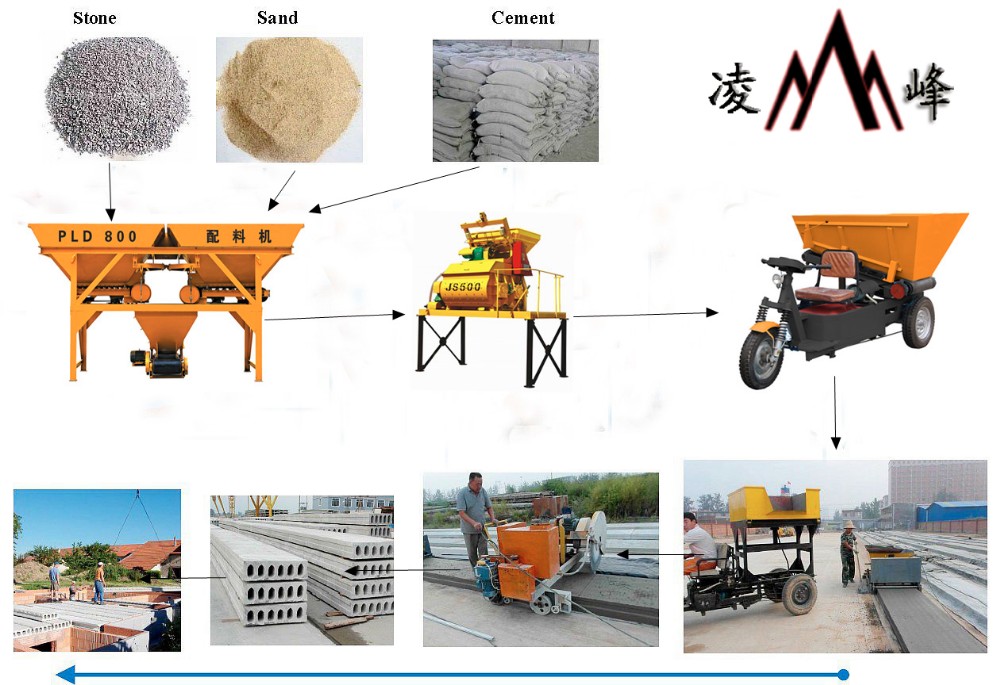

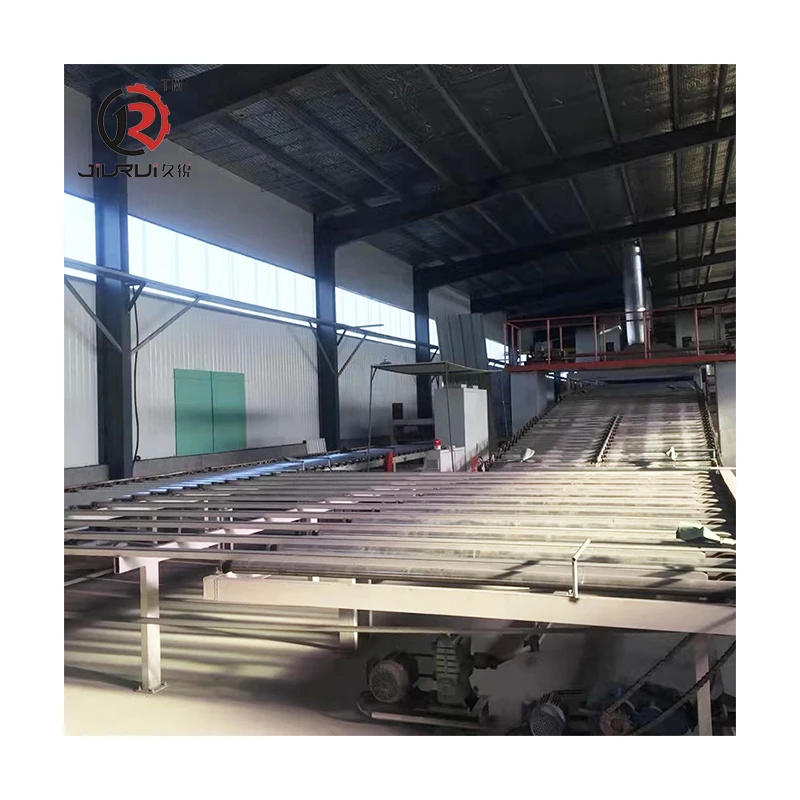

precast concrete slab, concrete slab making machine, concrete slab machine works on the long-line table, using the high-strength low-relaxation steel strand as the guide, using the pushing work method to forming the concrete hollow-core slab. The slabs have the advantages of smooth surface, high-density structure, capable of making construction slabs of 4.2m to 18m. The GLY series concrete hollow-core slab mainly used on the larger bay workshop, school, hospital, shopping mall, office building, bulk storage plant etc.

Load and span of Precast Hollow Core Concrete Slab Making Machine For Roof and Floor ---Normal form

Slab size (Thickness x Width)(mm) | Max. length (m) | Max. load (Kn/m2) | Dia. of steel when max. load (mm) | No. of steel when max. load | Holes No. |

100x600 | 5.1 | 8.11 | Φ7 | 5 | 6 |

120x600 | 6.0 | 8.86 | Φ7 | 6 | 5 |

150x600 | 7.5 | 10.24 | Φ9.5 | 5 | 4 |

180x600 | 9.0 | 16.16 | Φ12.7 | 4 | 3 |

100x900 | 5.1 | 9.76 | Φ7 | 10 | 10 |

120x900 | 6.0 | 8.86 | Φ7 | 9 | 8 |

150x900 | 7.5 | 10.24 | Φ9.5 | 10 | 6 |

180x900 | 9.0 | 16.16 | Φ12.7 | 9 | 5 |

200x900 | 10.2 | 13.22 | Φ12.7 | 7 | 6 |

250x900 | 12.6 | 11.10 | Φ12.7 | 7 | 6 |

300x900 | 15 | 10.83 | Φ12.7 | 8 | 5 |

SP Hollow Core Slab Form

Model | Power(kw) | Molding speed(m/min) | Max Slab Length(m) | Quantity of Steel strand/Diameter | NO. of holes/Shape | carrying capacity(KN/m*m) |

GLY150*900 | 10.5 | 1-1.2 | 7.5 | 10/7 | 9/Oval | 2.451 |

GLY150*1200 | 15.5 | 1-1.2 | 7.5 | 14/7 | 13/Oval | 2.459 |

GLY 180*900 | 10.5 | 1-1.2 | 9 | 7/9.5 | 8/Peach | 2.815 |

GLY 180*1200 | 19 | 1-1.2 | 9 | 10/9.5 | 11/Peach | 2.837 |

GLY 200*900 | 19 | 1-1.2 | 10.2 | 7/12.7 | 6/Peach | 3.139 |

GLY 200*1200 | 22 | 0.8-1 | 10.2 | 10/12.7 | 8/Peach | 3.142 |

GLY 220*1200 | 22 | 0.8-1 | 11 | 10/12.7 | 8/Peach | 3.495 |

GLY250*900 | 22 | 0.8-1 | 12.6 | 7/12.7 | 6/Peach | 4.133 |

GLY250*1200 | 26 | 0.8-1 | 12.6 | 10/12.7 | 8/Peach | 4.135 |

GLY300*900 | 26 | 0.8-1 | 15 | 8/12.7 | 5/Peach | 4.361 |

GLY 300*1200 | 31.5 | 0.7-1 | 15 | 12/12.7 | 6/Peach | 4.573 |

GLY 380*900 | 31.5 | 0.7-1 | 18 | 10/12.7 | 5/Rhomb | 5.778 |

GLY 380*1200 | 40 | 0.7-1 | 18 | 14/12.7 | 7/Rhomb | 5.759 |

Product features of Concrete Hollow Core Roof Panel Machine :

Strong limberness: The length and width of the hollow plate and the size of the specification can be customized according to the actual needs of the project. No template restrict, more than ten kinds of models can be chosen. And according to the building function and model, it can be cutting angle, circle, cantilever.

Energy saving and high efficiency: The hollow plates adopt extrusion production process, no template and steam curing, reduce the labor intensity, improve the production efficiency.

Reasonable design: The hollow plates adopt one way reinforcement member, the stressed tendons is steel strand, toughness, strength, structural design is reasonable, better than similar sheet.

Save time and labor, reduce costs: The hollow plates directly used as floor slabs or roof slabs, not only save the plastering process, save both labor and money, but also avoid plastering cracks. Compared with the cast-in-place plate, it has the advantages of low steel bar consumption, low price, light load, simple construction process, short construction period, reduced labor and material cost, etc. So it reduces the whole construction project cost.

We can produce the machine according Customers Design for slabs.

To Quote you the Whole production line price, please kindly let us know what

specification of Hollow core slabs you want to produce? Slab thickness? Width? Or let us know the Max span you need?

Похожие товары

Машина для производства железобетонных стеновых перегородок

Сборная машина для изготовления плит 100x300x2 двухлинейный скользящий станок продажи

Панель для облицовки бетонной плиты

Установка для производства пеноизоляционных блоков

Машина для изготовления сборных бетонных стеновых панелей

Сборная машина для изготовления бетонных плит полый сердечник бетонная армированная напольная плита

Стеновая панель для бетонного забора сборный бетон

Новые поступления

Новинки товаров от производителей по оптовым ценам