Автоматический сервопривод для стиральной машины Инверторный двигатель автоматическая обмоточная машина внутреннего статора BLDC игольчатая обмотка

- Категория: Electric Equipment Making Machinery >>>

- Поставщик: Ningbo Nide Mechanical Equipment Co. Ltd.

Сохранить в закладки 60424259983:

Описание и отзывы

Характеристики

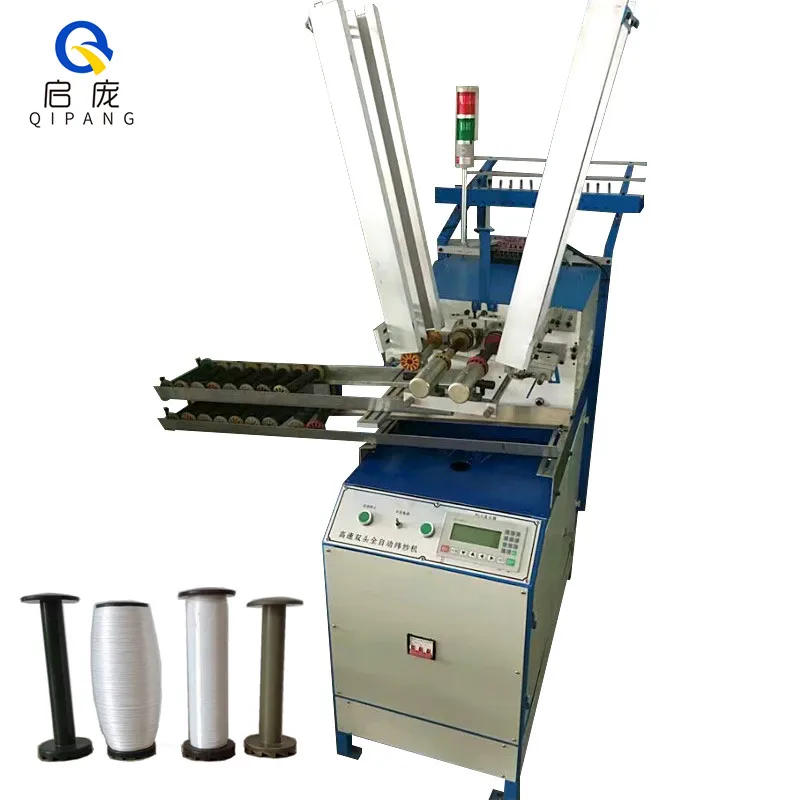

Servo BLDC washing machine inverter motor automatic coil winding machine/ inner stator needle coil winder equipment

(1)Introduction :

The motor stator coil winding machine is aimed at Inverter brushless motor manufacturing, adopts double-station needle winding design technology, Mainly used for multi-pole stator winding. manual feeding, automatic clamping die, Multiple tap (screen setting), wire clamping and wire cutting can be realized during winding process. Each action cycle will wrap 2 stators, greatly improve the production efficiency, reduce labor intensity. The number of slots and cycles can be set by man-machine interface; Electric by PLC, display, servo motor control, set and display, safe and reliable.

(2)Application:

The automatic motor winding machine is especially suitable for Inverter washing machine motor, Inverter cleaner motor and other BLDC/brushless motor.

(3)Function and Characteristics:

1,For multi-pole BLDC motor stator winding, manual loading and unloading, automatic clamping, winding and shearing;

2,The frame adopts thickened aluminum profile, and the table plate adopts cast iron to absorb vibration, even when winding at high speed, the vibration is very small.

3,Tooling and fixture parts adopt downward positioning mode, stable positioning and reliable tightening.

4,Wire clamping and wire cutting, line part structure compact, wire clamping and wire cutting is completed at one time;

5,Quick change-over of tooling;Different stator and winding parameters can be quickly switched through the HMI to adapt to different stator requirements.

6,PLC control, fault display

7,Double stations high-speed needle winding

(4)Specification:

| Product name: | Double stations Inverter motor stator automatic winding machine |

| Stator ID: | φ25—φ60 mm (customizable) |

| Stator OD: | φ60—φ200 mm (customizable) |

| Stack length: | 10-200mm(customizable) |

| Wire diameter: | φ0.13—φ1.2 mm(customizable) |

Spindle speeds: | 0-600 RPM adjustable |

Air pressure: | 0.5-1MPa |

| Applicable pole number: | multi polar |

| winding technology: | needle winding |

| winding station: | double two |

| Voltage: | 380V/50HZ Three phase four wires |

| Power: | 20KW |

| Weight: | 700KG |

| Dimension: | 1300*1100*1700mm |

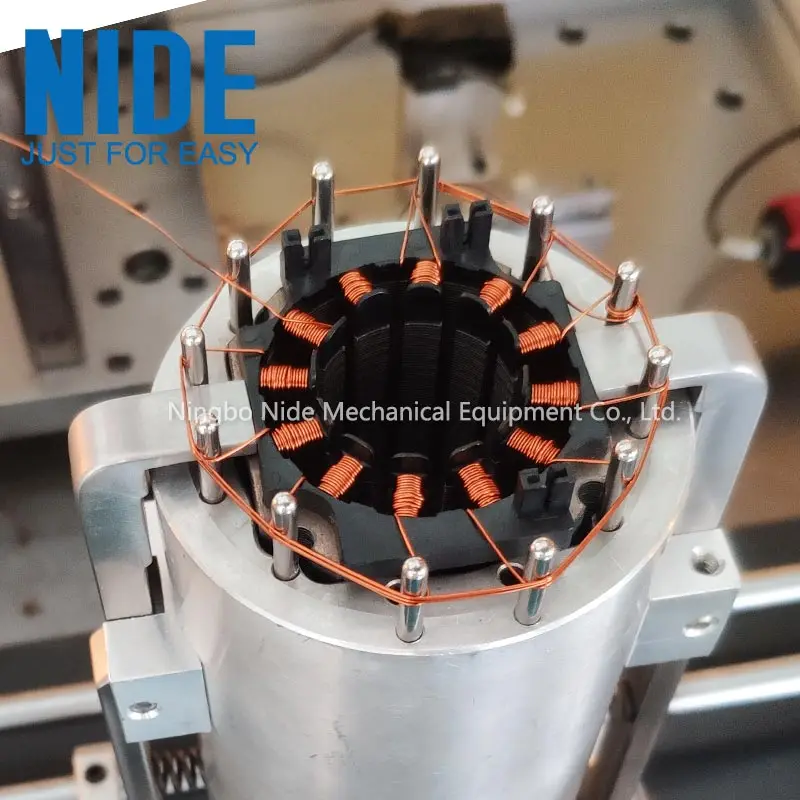

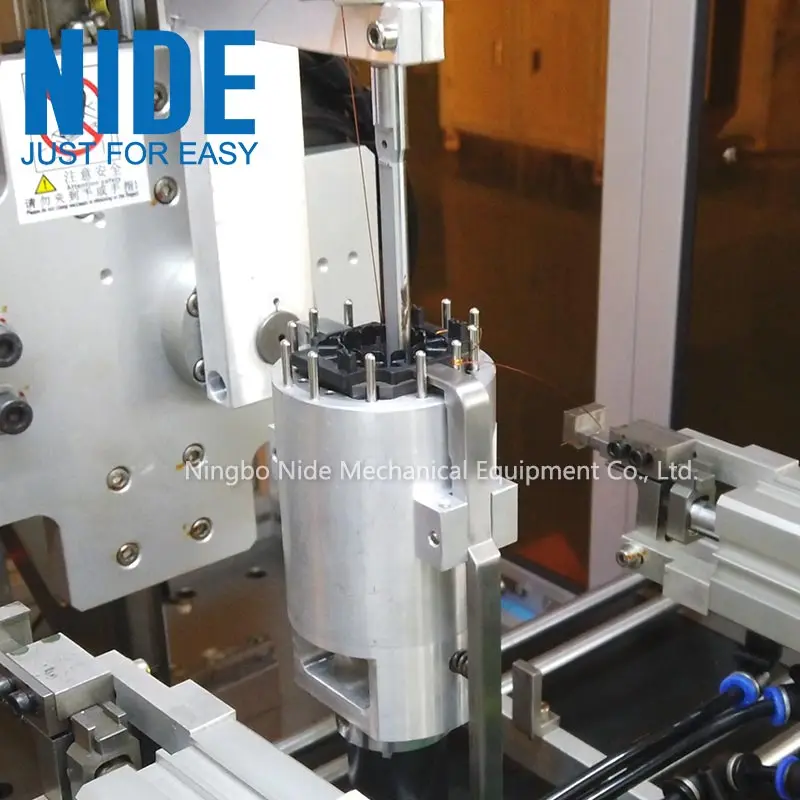

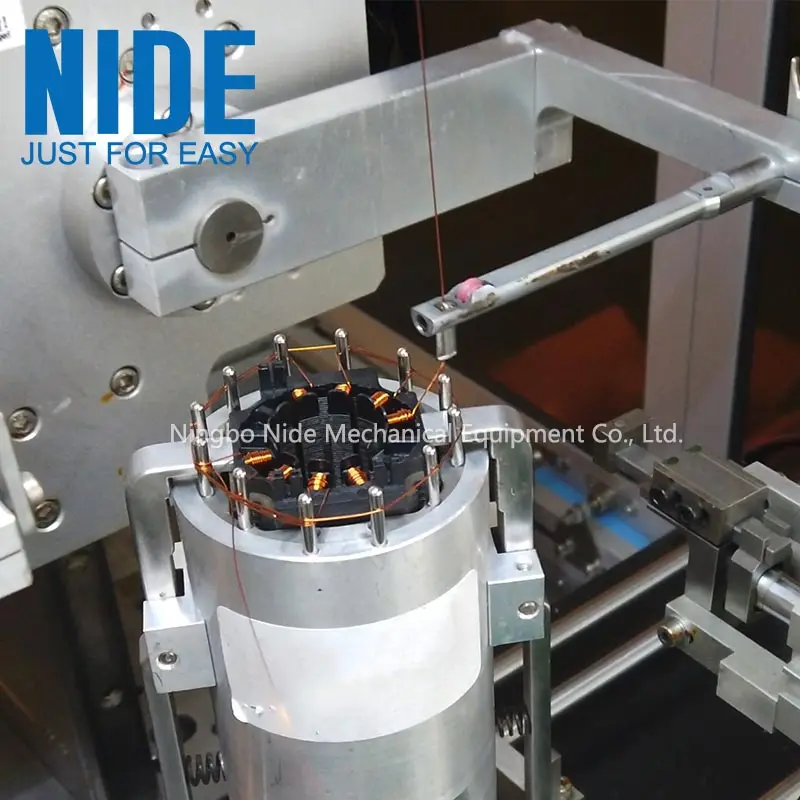

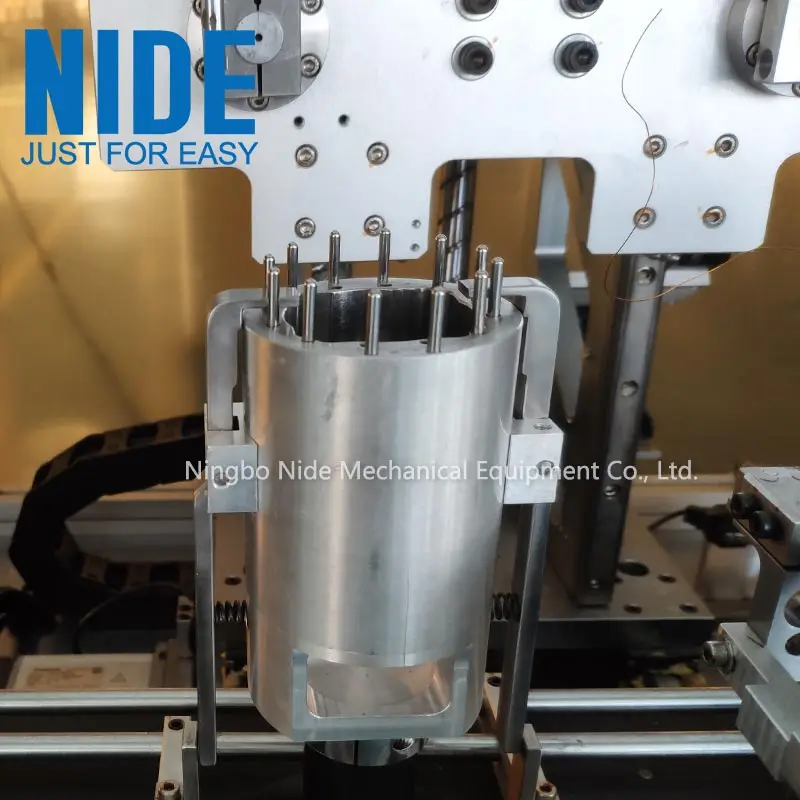

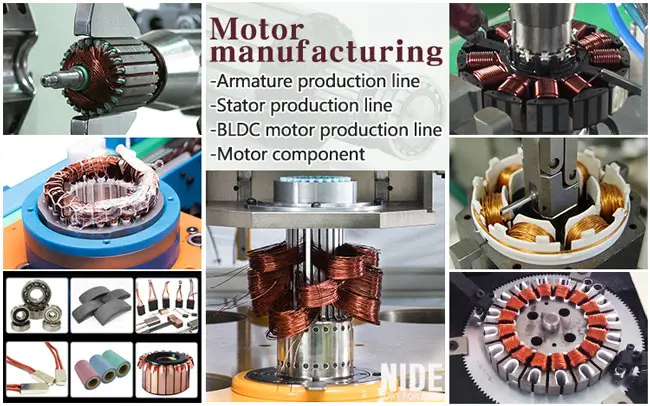

(5)Picture show

Motor stator manufacturing production assembly line including paper inserting machine, coil winding machine, coil winding inserting machine, lacing machine, forming machine and testing machine.NIDE can supply and manufacture about then ,and all the process will be done by machine automatically. Operator only needs to do loading and unloading.

With good service, unique philosophy, professional team and reliable quality, we win the worldwide customers' confidence gradually. We directly and indirectly supply our products to more than 50 countries.Among the customers, many of them are the world-renown companies.

| Customerized service | 1. Customized product design and manufacturing |

| 2. Customized tranning | |

| 3.Technical suggestions | |

| After-sales service | 1. Warranty Period: 12 month usually |

| 2. Overseas service center available | |

| 3. Engineers available to service overseas |

Established in 2007, Nide is a company devoted in the field of electric motors manufacturing, providing one-stop service for its customers.

Nide has three main business divisions.

The first division is to provide different kinds of motor manufacturing machinery, it is our Main business, including stand along machine, fully-auto complete line for armature and stator production, and the motor assembly line.

The second division is to supply the full range of motor components such as commutator, ball bearing, carbon brush, insulation paper, shaft, magnet, fan, motor cover,etc.

The third division is to provide technical support and consulting, project support and turn-key service for some motor manufacturing.

Our machines are mainly applied to induction motors, BLDC motor, universal motor, three phase motor, single phase motor, AC motor, DC motor, such as washing machine motor, air conditioner motor, pump motor, cooler motor, alternator motor, fan motor, ceiling fan motor, compressor motor, power tool motor, vacuum cleaner motor, mixer motor, series motor, electrical car motor, wheel hub motor, electric toothbrush motor, hair dryer motor, electric shaver motor,etc.

Похожие товары

Dhy-200 три в одном, гидравлический шиномонтажный станок, ручной медный шиномонтажный инструмент

SRB22-1A проволочная катушка из нержавеющей стали для электронной сигареты

Машина для подвязки проводов, машина для подвязки проводов, машина для подвязки проводов

Станок для катушек, станок для намотки катушек, станок для намотки катушек, станок для подвязки проволоки

Odetools TY-8WA провода катушечная Обмотка Машина провод катушки обмотки машина электрическая машина для намотки проволоки для строительства

Автоматическая Высококачественная машинка для связывания и подвязки с кнопкой управления кабелем, машинка для связывания проводов

Машина для перемотки полиэфирной пряжи, катушка для намотки пряжи, машина для подвязки проволоки

Новые поступления

Новинки товаров от производителей по оптовым ценам