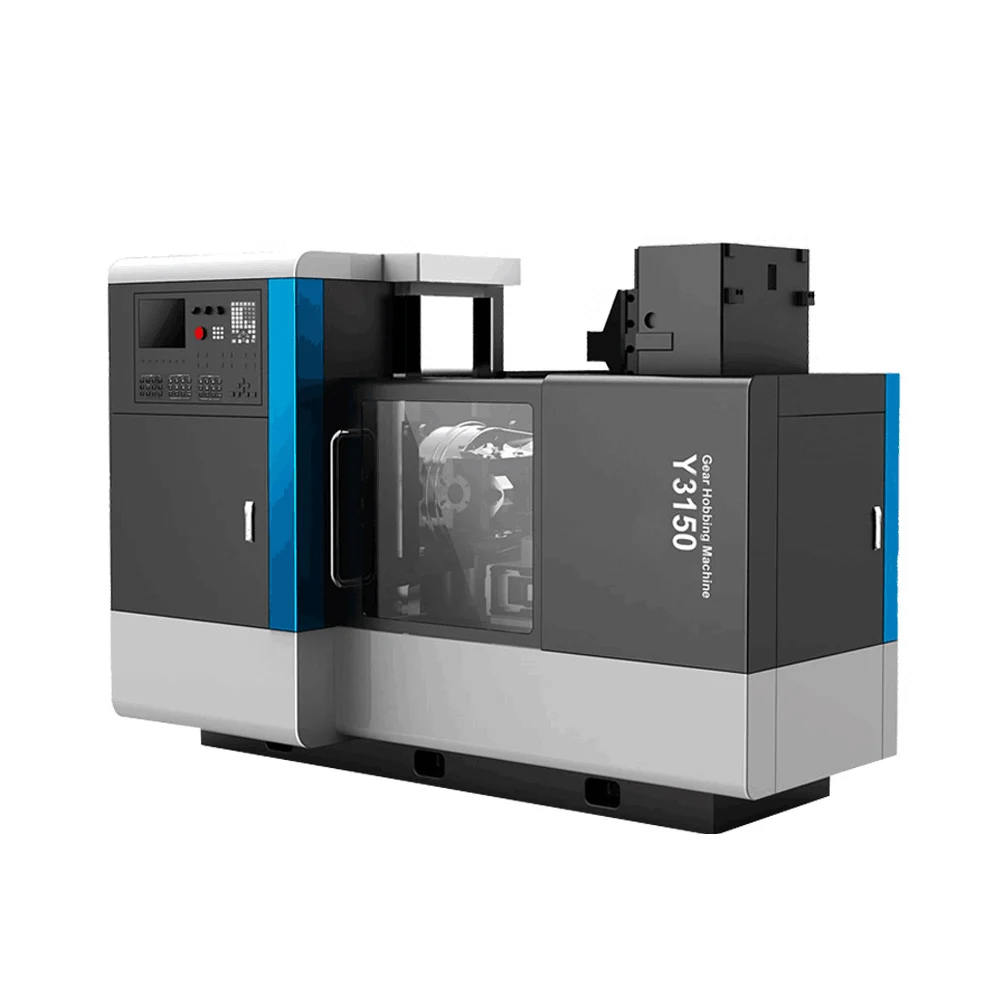

Y3150 цепное колесо/червячный зубчатый станок/прямой/Спиральный

- Категория: Зуборезные станки >>>

- Поставщик: Xingtai Paisen Commercial Co. Ltd.

Сохранить в закладки 60451221785:

Описание и отзывы

Характеристики

Y3150 chain wheel gear/worm gear hobber machine/spur straight/helical hobbing machine

Gear hobbing machine is a special form of milling machine that cuts gears. It is the major industrial process for cutting (as opposed to grinding) spur gears of involute form.

The machine forms the gear via a generating process by rotating the gear blank and the cutter (called a hob) at the same time with a fixed gearing ratio between hob and blank. The hob has a profile given in cross-section by the fundamental rack for the gear tooth profile and is in the form of a helix so that the sides of the teeth on the hob generate the curve on the gear. The helix has a number of cuts parallel to the axis to form the cutting teeth and the profile is suitably relieved to provide cutting clearance.

Application of the gear hobbing machine

Gear-hobbing machines use a rotating, multiple-tooth cutting tool called a hob for generating teeth on spur gears, worm gears, helical gears, splines, and sprockets. More gears are cut by hobbing than by other methods because the hobbing cutter cuts continuously and produces accurate gears at high production rates.

Hobbing is a machining process for making gears, splines, and sprockets on ahobbing machine, which is a special type of milling machine. The teeth or splines are progressively cut into the workpiece by a series of cuts made by a cutting tool called a hob. Compared to other gear forming processes it is relatively inexpensive but still quite accurate, thus it is used for a broad range of parts and quantities.

It is the most widely used gear cutting process for creating spur and helical gears and more gears are cut by hobbing than any other process since it is relatively quick and inexpensive.

Feature of the gear hobbing machine

1. The machine is suitable for large batch and single production of cylindrical spur and helical gears, worm gears, sprocket, chain wheel gears, straight tooth gear.

2. The machine is characterized by good rigidity, high strength, high working accuracy, and easy in operation and maintain.

3. The machine can be operated not only with forward and backward cutting, but also with axial or radial feed.

Model | Y31125ET | Y3180H |

Max workpiece diameter(with rear column/without rear column) | 1000MM | 550MM |

2200MM | 800MM | |

Max hobbing modulus | 16MM | 10MM |

Max Processing Width | 500MM | 300MM |

Min processing gear | Z/K=12 | Z/K=8 |

Max vertical travel of tool post | 800MM | 350MM |

max swiver angel of tool post | ±60° | ±240° |

Distance between cutter axis and worktable | Max1000MM | Max585MM |

Min200MM | Min235MM | |

Spindle taper | Morse 6 | Morse 5 |

Hob diameter | Max Dia 245MM | Max Dia 180MM |

Min length 220MM | Min length 180MM | |

Max axial movement of cutter | 100MM | 50MM |

Hob abor diameters | Φ27,Φ32,Φ40,Φ50MM | Φ22,Φ27,Φ32,Φ40MM |

Distance between hob axis center and worktable | Max 1250MM | Max 550MM |

Min 100MM | Min 50MM | |

Worktable aperture | 200MM | 80MM |

Taper bore of workpiece mandrel | Morse 6 | Morse 5 |

Worktable diameter | 950MM | 650MM |

Spindle rotate speed and range | 7level 16-125R/Min | 8Level 40-200R/Min |

Rapid travel speed of tool post slide | 520MM/Min | ≤540MM/Min |

Worktable rapid moving speed | 470MM/Min | ≤540MM/Min77 |

Distance between worktable and outer support of axis face | Min700MM | Min400MM |

Max1200MM | Max600MM | |

Axial feed rate and degree | 8Level 0.39-4.39MM/R | 12Level 0.4-4MM/R |

main motor power and synchro-speed | 11Kw 1500R/Min | N=5.5Kw 1500R/Min |

Axial rapid motor power and synchro-speed | 3Kw 1500R/Min | N=1.1Kw 1500R/Min |

Worktable rapid motor power and synchro-speed | 1.5Kw 1000R/Min | N=0.55Kw 1500R/Min |

Hydraulic oil pump power and synchro-speed | 1.5Kw 1000R/Min | N=1.1Kw 910R/Min |

Cooling pump power and synchro-speed | 1.5Kw 1500R/Min | |

Machine weight | 15000Kg | 5500kg |

Overall dimension | 3995*2040*2700MM | 2752*1490*1870MM |

XINGTAI PAISEN COMMERCIAL CO.,LTD is managed by principles of value creation & we add value to our customers by supplying innovative products & services based on our in-depth understanding of our customer needs and requirements.

Help you find the right product for the right job! At PAISEN, we are committed to providing the highest level of customer service, competitive pricing, speedy delivery and a comprehensive, cutting-edge product offering.

Welcome to visit our factory to creat a better future!

Our Service:

1.Any inquiries will be replied within 12 hours

2.Professional manufacturer, Welcome to visit our factory at any time

3. OEM services are welcomed, and we can help you to print your logo, company information etc on our products and package .

4.High quality, fashion designs, reasonable & competitive price and fast lead time

5.After-sale service

6.Faster delivery

7. Protection of your sales area, ideas of design and all your private information

You can pay for the order via: T/T, western union.

8.Shipping

sea shipping

We have strong cooperation with DHL, TNT, UPS, FedEx, EMS, China air post

You also can choose your own shipping forwarder

Air express | 1).FedEx,UPS,TNT:Time 5 days range. |

2).DHL:Time 3 days range. | |

3).EMS:Time 20 days range. | |

4).Or other express. | |

Air express a long-term cooperation,The price favorable |

1.Is your product good quality?

Answer: Our products are all in good quality and cheap price.

we can satisfy different customer's requirements.

2.Can you give me a discount?

Answer:we are wholesale company, our policy is that bigger quantity,cheaper price,

so we will give you discount according to your order quantity.

3.The shipping cost is too high, can you give me more cheaper?

Answer:When we calculate the shipping cost for you, we will use the cheapest and safest courier,

and it is shipping company who ask us to pay, we can't give you cheaper, pls kindly understand.

However we can promise that we will not ask you to pay more shipping cost

Why cooperate with us?

We view each customer as a relationship, not just a sale. Thank you for shopping here and please feel free to connect with us. Remember, if you have questions or concerns please just ask.

Call us today, and let us help you find the right product for the right job!

Our ultimate goal is your satisfaction!

contact:

website: //xtpaisen.en.alibaba.com/

Mobile: +86 13363750731 ( add wechat/whatsapp/)

13363750731( wechat)

.

Похожие товары

YKL31630 2 оси Зубофрезерный станок с ЧПУ/фрезерный ЧПУ зубчатой передачей

Фрезерный резак

YK3150E Высокая точность 4 оси ЧПУ шестерни hobbing машина цена

Высокая скорость шестерни делая машину Y3150 Универсальный Зубофрезерный станок

Y31200 зубчатая режущая машина, Китай, ручная зубчатая машина

Automatic heavy duty Gear cnc Shaping Hobbing

Малый зубчатый станок для резки Макс 6 модуль Y3150-3

Новые поступления

Новинки товаров от производителей по оптовым ценам