Пластина для пластиковых пакетов из нейлоновой смолы толщиной 6 35 мм

- Категория: Printing Plates >>>

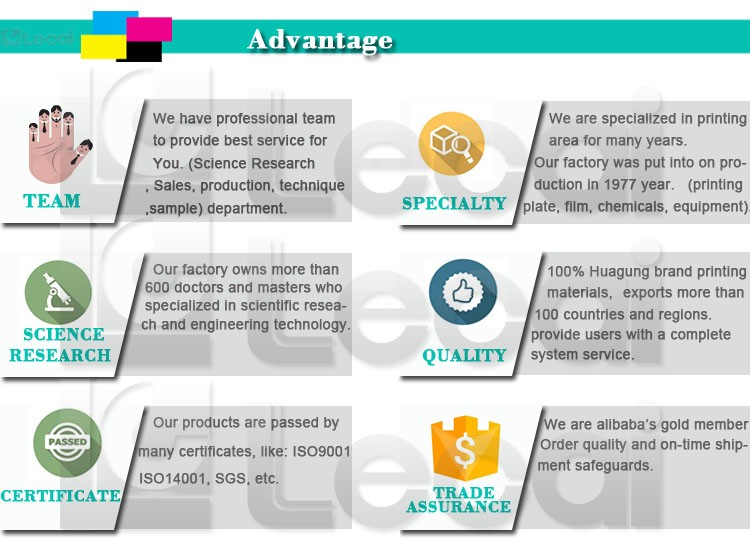

- Поставщик: Hangzhou Lecai Advertisement Printing Material Co. Ltd.

Сохранить в закладки 60453789249:

Описание и отзывы

Характеристики

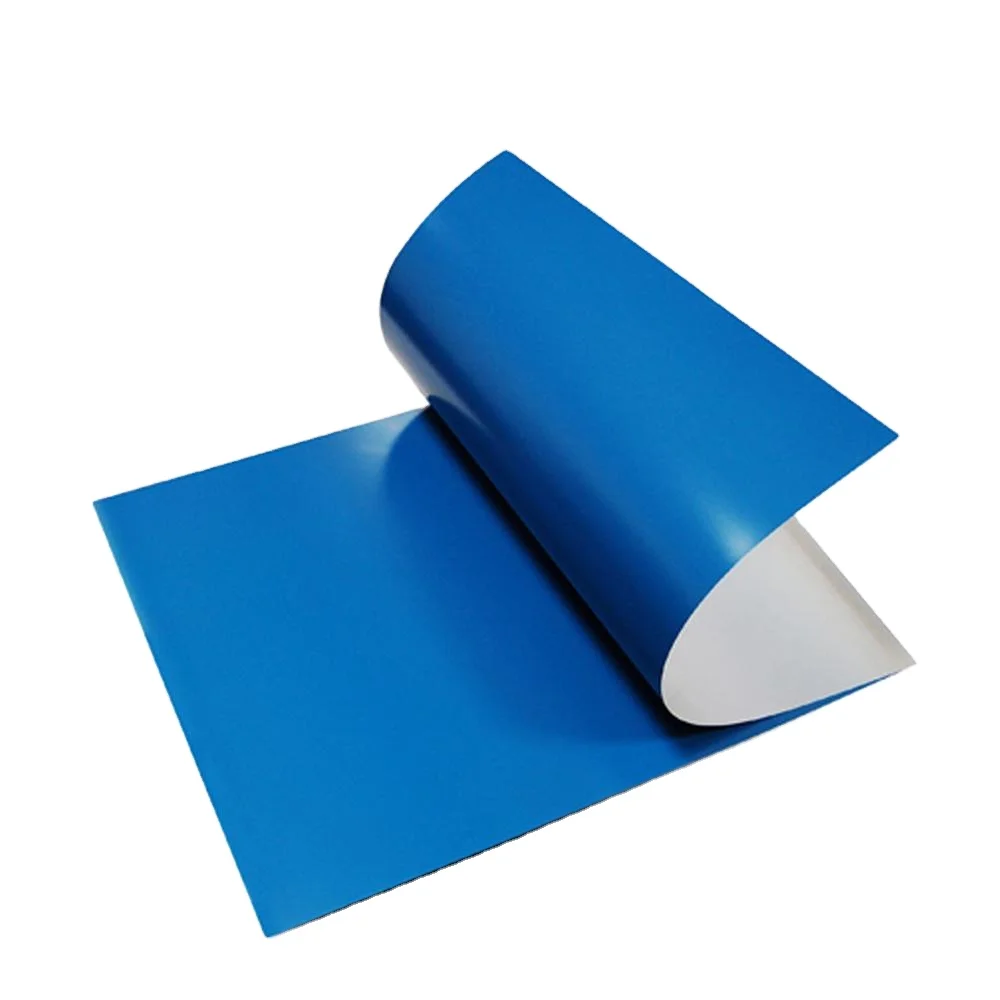

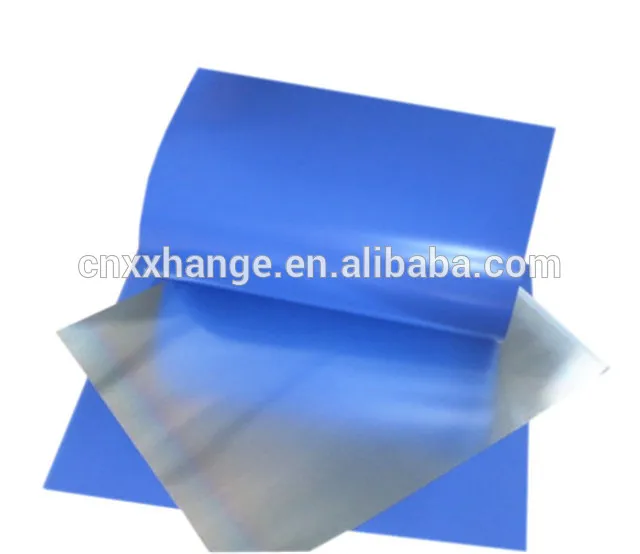

6.35mm Thickness Nylon Resin Flexo Printing Plate for Plastic Bags

Flexo Plate Description

1)Excellent dot and isolated line reproduction

2)Solid printing performance

3)High latitude of exposure and processing

4)Good ink transfer

5)High impression

Flexo Plate Product Specification

| Type | R-635 | |

| Thickness(mm) | 6.35mm | |

| Rigidity(Shore A) | 36-33 | |

| Recommend relief depth(mm) | 2.2-3.0 | |

| Image reproduction | 3%~95% | |

| Maximum line line/inch | 85 | |

| Minimum isolated line | 0.3mm (0.0118inch) | |

| Minimum isolated dot | 0.50mm (0.0197inch) | |

| Suitable ink | Suitable for water and alcohol-based ink, incompatible with oil-based ink, hydrocarbon solvent or the ink containing ethyl acetate of more than 25% | |

| Mainly applicable field | Corrugated board | |

| Size mm (inch) | 457×762 (18×30) | √ |

| 762×1016 (30×40) | √ | |

| 762x1067 (30x42) | √ | |

| 900×1200 (35.4×47.2) | √ | |

| 1067×1524 (42×60) | √ | |

| 1067×2032 (42×80) | √ | |

| 1200×2032 (47.2×80) | —— | |

| 1200×2500 (47.2x98.4) | —— | |

| 1270×2532 (50×80) | —— | |

Flexo Plate Process parameters

| Type | R635 | |

| Thickness(mm) | 6.35mm | |

| Back exposure(seconds) | 160-240 | |

| Main exposure(seconds) | 12-24 | |

| Rinsing(minutes) | 9-12 | |

| Minimum drying time(hours) | 3-4 | |

| Detackfying(minutes) | 5-8 | |

| Post exposure(minutes) | 5 | |

1) Platemaking conditions: light of 80 watts (9.7mW/cm2 under 365nm), platesetter temperature 24-30 °C.

2) All the above data is depended on our plate-making device. Due to the different requirements of plate-making device, UV lamp power, relief depth and print image, the above recommended time can be changed appropriately. Customers should test on their own device for optimum plate quality.

Похожие товары

Микрокристаллическая магниевая пластина с покрытием для фотогравировки

Офсетная позитивная термическая печатная плата ctp на станке для производства CTP

Цифровая Фотополимерная Пластина AOLIDE толщиной 1 70 мм для флексографической печати упаковки

Китай, Топ бренд Amsky, офсетная пластина, УФ ctp ctcp машина для продажи

Положительная CTCP пластина алюминиевая печатная пластина компьютер к обычной пластине

Соль, белый цвет тела, взрослые, производство магния, возрастное химическое место, модель, ароматизатор группы SHN сульфат, ингредиент, соль эпсома, соль для ванны

CTP пластина без разработчика для химической бесплатной фоточувствительной пластины

Новые поступления

Новинки товаров от производителей по оптовым ценам