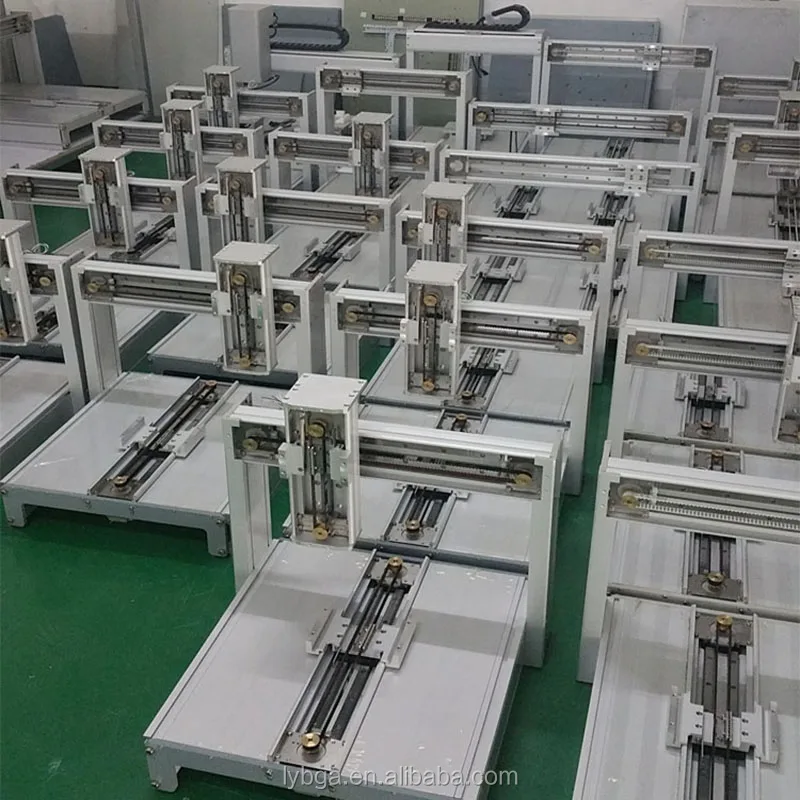

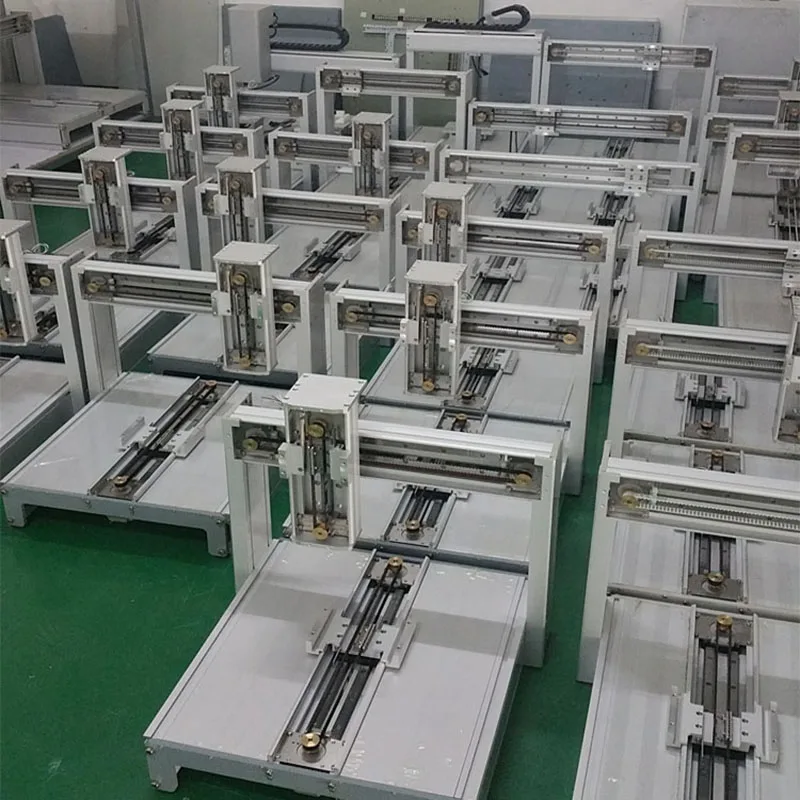

Полностью автоматическая винтовая блокировочная машина для сборки электротоваров

- Категория: >>>

- Поставщик: Shenzhen Liyang Welding Equipment Co. Ltd.

Сохранить в закладки 60458092313:

Описание и отзывы

Характеристики

fully automatic screw locking machine for electric products assembly

Specifications:

Purpose: screw

Output speed: 2 / SEC

input voltage: dc 15 v / 1500 ma

Features:

1, versatility. Small size, can work with the production line, the product easy to replace.

2. Flexibility: can be selected according to the number of electrical batch of products, such as installed four electric screwdriver while lock pay four screws, one machine can simultaneously lock pay several products. Z-axis batch number can be customized according to customer requirements.

3, reduce labor intensity, the traditional manual placement and alignment of the screw head of the screw would take a lot of work time and effort.

4, the high degree of automation. Simple, staff rapidly and master the operation and commissioning, a worker can manage several machines, saving labor.

5, torque precision, easy to adjust, to ensure the quality of the lock.

6, screw shaped filter, using the turbine materials, low noise, small surface damage on the screw, to feed straight vibrator fast and stable, straight vibrator on automatically filter shaped screws, linear transducer to ensure that the material feed to the front end of the sub-feeder non-material anomalies, lack of material straight vibrating alarm automatically.

7, stability is not the material, in the lock pay process, complete a normal lock screws, automatic screw screws to send a batch of mouth, if the torque can not reach, do not send screws to batch mouth, will not occur due to repeated feed card screw phenomenon, even if due to poor screw cause the material, non-professionals can also solve the problem of feeding the card within a few seconds.

8, clean, by omitting to take the hand screw action will not stain hands generated when screws take the product to generate secondary pollution and sweat stained hand screw it easier to rust.

9, durable machines, key components are selected high-quality alloy steel through special heat treatment and various pneumatic and electrical components are selected original parts to ensure that millions of screws zero failures.

10, intelligent production, production schedule to control in place, eliminating the need for hiring, training, automated production, establish a modern image production.

Packaging:

Packaging material: Carton/Wooden case with foam inside.

Shipping:

A. 3-5 workdays shipping from China by Air/Express(DHL,FedEx,UPS,EMS etc.)

B. 3-5 workdays shipping from UK Warehouse to European union countries.No need to pay for customs duties and VAT.

C. 25-30 workdays shipping from China to Russian customers. No need to pay for customs duties and VAT.

D. We can arrange shipment by sea. Minium CBM requirement : 1 CBM

1.We provide you the friendly English User manual or operating videos for free.

2.24 hours technical support by email or calling.

3.Warranty: 1 year free, 2-3 years cost price and free technical support always.

4.Free training to make sure you master the operating of our products.

5. OEM/ODM accept . But the MOQ of OEM/ODM is 100 sets.

LyBGA factory is located in Shenzhen, China.

Our factory owns 2 brands , Ly and Bauer.

We has 10 years experiences in manufacturing and exporting BGA rework stations.

Our BGA rework stations , such Ly IR6000, Ly IR6500, Ly IR9000,Ly IR-PRO-SC, Ly IR8000, Ly HR560, Ly HR560C, Ly HR500, Ly SV550C, Bauer IR-PRO-SCC ,Bauer OMEGA XD …

CNC machines like cnc 3020/4030/6040/9060 …series products ,Mobile LCD separating stationslike 946D /947B /950V/948V/948B…are hot sale in the world, especially in these countries from North and South American,European and Asian.

Похожие товары

Металлический жесткий эмалированный металлический значок на заказ, булавка для лацкана в подарок с бабочкой

Автомобильная камера заднего вида с металлическим корпусом, 24 месяца гарантии

Б/у Doosan DH210W-7 колесный экскаватор-погрузчик для продажи б/у

Новая технология, легкие наушники Somostel J18, беспроводные наушники с Bluetooth, миниатюрные наушники-вкладыши со светодиодным дисплеем

Машина для выпрямления листовых металлов

160Kw READ2100P контроллеры двигателей с электронным дифференциальным контроллером для аэропорта шины

Установка для очистки воды с УФ и озоновой системой

Новые поступления

Новинки товаров от производителей по оптовым ценам