Большой трафарет ультразвуковой очиститель индивидуальная Высокоэффективная машина для чистки шелкографии

- Категория: Ultrasonic Cleaners >>>

- Поставщик: Guangzhou Huanan Ultrasonic Equipment Co. Ltd.

Сохранить в закладки 60467792443:

Описание и отзывы

Характеристики

Technical Parameter:

1.Transducer quantity: 36pcs

2.Ultrasonic frequency:28 KHZ

3.Motor Power:250W

4.Recycle pump:250W

5.Spary pump: 2.2KW

6.Frequency Converter power:0.75KW(attached user manual)

7.Electrical control box electrical power: there wire/40A:Blue color null line(N)

Brown color Phase line(L),yellow-green ground line(PE)

8.Electricity require:220V/50KHZ(40K),Air leakage switch.

Machine Description:

1. The machine is special design for cleaning screen frame,frame size:240cm(L)*130cm(W)*4cm(H)

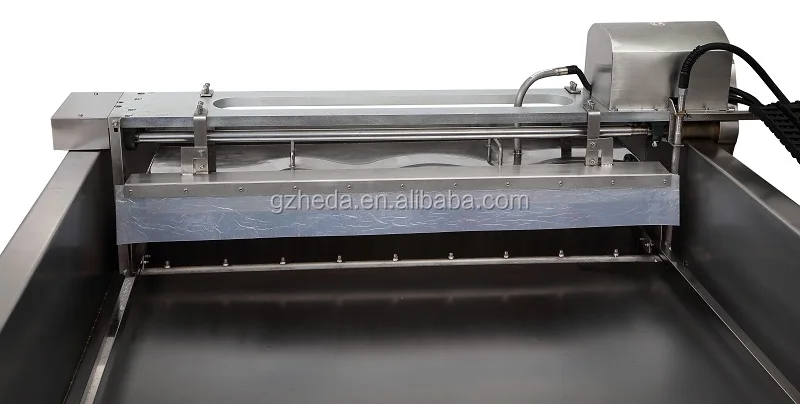

2. Ultrasonic vibration bar:250mm*1250mm*100mm made of 3mm thick 316L stainless steel

3. Cleaning tank material: 2.5mm thick 304 stainless steel.

4. The machine is controlled by MITSUBISHI PLC(Programmable Logic Controller). The cleaning and Rinsing are both automatic.

Machine Work Flow:

1.Put the screen frame into cleaning tank.

2.Pump the cleaning liquid from reservoir to cleaning tank until the screen frame is submerged.

3.Press down ultrasonic button to start ultrasonic cleaning.Can set the cleaning time on PLC.

4.Cleaning finished.Pump the cleaning liquid from tank to reservoir.

5.Rinsing screen frame by injector.

6.Rinsing finished,take out the screen frame from the tank.

Cleaning Process:

The ultrasonic box device will slide forward and backward upside the screen frame. One cycle(backward and forward)needs 5~10 minutes.The screen frame will be clean completely after one cycle ultrasonic box device movement.

Remark: the cleaning water must mixed with cleaning chemical.

Rinsing Process:

1.The system will automatic fill city water to water pipe(see picture) after ultrasonic cleaning finish and cleaning liquid is pumped back to reservoir. Then the injector will spray city water to screen frame,Rinse process begins.

2.There are two water pipes.One pipe is installed on upside of screen frame.Another pipe is installed one downside of screen frame.

3.Injectors are fixed on the water pipe and city water spray to screen frame with pressure.

Two water pipe slide backward and forward.Rinse process finish after one cycle(backward and forward).

Machine graphic design

Real Machine Images:

Похожие товары

Портативная мини-машина для уборки, персональный бытовой ультразвуковой очиститель для очков, часов, ювелирных изделий

3 мин стиральная машина цифровой ультразвуковой очиститель для очков часы ювелирные изделия

Лидер продаж 2020, уход за красотой, Домашнее использование, Кисть для макияжа, очиститель ювелирной ткани, ультразвуковой очиститель

Цифровой медицинский инструмент для зубных протезов, ультразвуковой очиститель, ультразвуковой очиститель двигателя

Smartclean Мини Ультразвуковой очиститель монет кольцо ювелирные Протезы eraclean для мини ультразвуковой стиральной машины

Портативный Ультразвуковой очиститель, цифровой очиститель для ювелирных изделий, ультразвуковой очиститель

Codyson Новое поступление ювелирные изделия Ультразвуковой очиститель D-3000

Новые поступления

Новинки товаров от производителей по оптовым ценам