Бесплатные технические чертежи дизайн ЧПУ обработка и накатка 5 оси полая трубка

- Категория: Stainless Steel Pipes >>>

- Поставщик: Nanjing Precision Engineering Co. Ltd.

Сохранить в закладки 60473006294:

Описание и отзывы

Характеристики

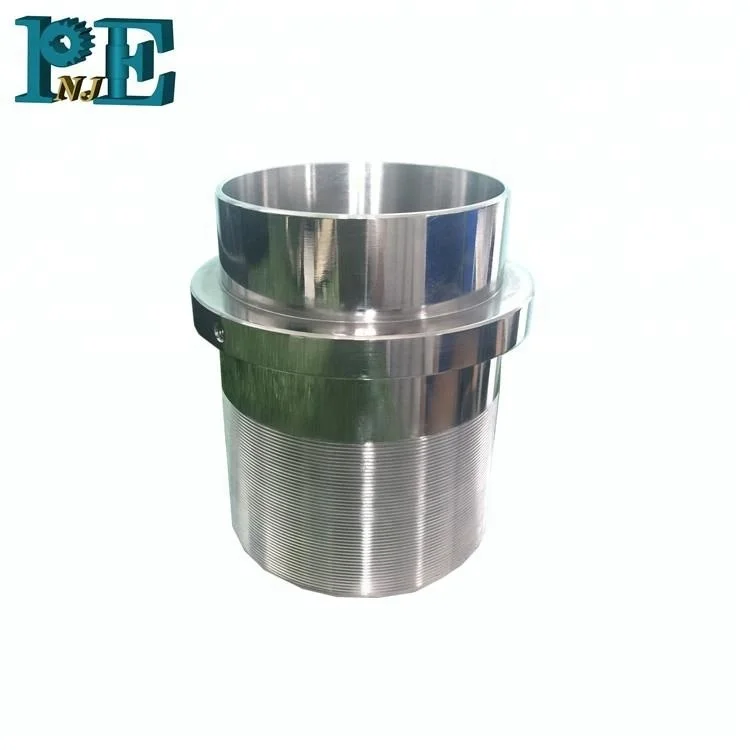

Nice quality cnc machining titanium grade 5 motorcycle parts

Description | motorcycle parts |

Material | Ti Gr 5 |

Process | cnc machining+deburrs+polishing |

Tolerance | ISO2768-M |

Surface | deburrs,degrease,chamfer |

Service Available | OEM & ODM |

Quality control | 0 defects,100% inspection before packing |

Delivery time | 7-25 days after confirm the drawings |

Logistics service | sea,air,express,EXW,FOB,CIF,DDU,DDP |

Warranty | 100% refund or replacement for NOK pcs |

All the products on our website can be customized!

1.R&D service

2.Drawing design service

3.Sample service

4.Bulk production service

5.Inspection service

6.Packing&shipping service

Packing and shipping for motorcycle parts

1.Packing: Inside:bubble bag

Outside:carton case or poly wooden case

2.Shipping: Small batch by courier,large batch by sea or air

motorcycle parts

1. ISO9001-2008

2. SGS

3. Material Certificate

4. CIQ...

1.Our company.

We(Nanjing precision engineering co.,ltd) are professional in manufacturing/CNC machining high precision metal parts, mechanical parts, and machinery parts in automotive, industrial automation, medical equipment, energy field, and bicycle by the process of cnc plus stamping/forging/casting/die casting/ extruding/ profile/laser cutting /carving /welding /fabrication /assemble ETC.

2.Factory workshop.

We have more than 15 years experience in development and research in OEM CNC machining parts, our factories were certified by ISO9001, also the equipments are advanced.

We are very familiar in CNC machining the material of the titanium, the brass, the copper, the aluminium, the stainless steel, the carbon steel parts..........

We are always trying our very best to find the best solutions to the customers by the competitive price,the good quality,the punctual delivery time,and the five-star service.

(1).Vcnc milling | ||||||

The workable length | 2-12000mm | |||||

The workable diameter | 2-6000mm | |||||

The tolerance | ISO2768-F | |||||

The operation system of the machines | FANUC | |||||

R & D engineering team design the technical drawings | STP, STEP, IGS, PRT, SLDPRT, AUTOCAD, PDF...... | |||||

3D dimensions inspection | CMM | |||||

(2).CNC turning | ||||||

The workable length | 2-12000mm | |||||

The workable diameter | 2-6000mm | |||||

The tolerance | ISO2768-F | |||||

The operation system of the machines | FANUC | |||||

R & D engineering team design the technical drawings | STP, STEP, IGS, PRT, SLDPRT, AUTOCAD, PDF...... | |||||

2D dimensions inspection | caliper,micrometer,altitude instrument,run-out instrument,roughness instrument....... | |||||

(3).The fabrication | ||||||

Our plastic injection machines could do the mold injection parts and the assembles from 0.005kgs to 1.5kgs,we are also experienced in the stamping,the bending,and the welding,our equipments are advanced in these fields,so we are always doing the exellent fabrication job.In the fabrication,we often use the melting welding,the pressure welidng,and the laser welding,the experienced technicians do the melting welding perfectly,the welding seam is straight,there are no gaps,no holes,no welding slags.All of our welding workpiece could pass the air-tight test successfully,our technicians also do well in the pressure welding and the laser welding,the workpiece is strong and beautiful. | ||||||

(4).The mechanical assemble | ||||||

The advanced euqipments, the professional R & D engineering team, and the complete inspection facilities enable us to the mechanical assemble with the high good quality level,the mechanical assembles have the good function and the long usage time. | ||||||

(5).The Surfact treatment | ||||||

Plating | 3+Cr,environmental,anti-corrosion maximum 480 hours salt spray test | |||||

Coating | powder coating,electrcial coating,maximum 480 hours salt spray test | |||||

Painting | environmental EXPOSY painting,cross-cutting test | |||||

Polish | satin polish,mirror polish,electrical polish, maximum 1200 grid | |||||

Dacromet | evironmental,anti-corrosion,maximum 560 hours salt spary test | |||||

Anodization | tumble,shot blast,sand blast.....,various color,maximum 480 hours salt spray test | |||||

Nylok | tight-locking,environmental,5 million times | |||||

Heat Treatment | adjust the mechanical properties,temper,normalization,quench...... | |||||

(6).The Variousl Material | ||||||||

Stainless Steel | SS304,SS304L,SS316,SS316L,SS430,SS201...... | |||||||

Aluminium | 7075,6061,6063,5082,5051,2014....... | |||||||

Brass | H62,H58,H59...... | |||||||

Steel | C20,C35,C45,C60...... | |||||||

Steel Alloy | 25CrMo,42CrMo,25Cr,40Cr,Q345,11SMn30...... | |||||||

Iron Cast | QT600,QT250,HT450,HT150...... | |||||||

Titanium Alloy | GR2,GR5,GR7,GR9...... | |||||||

Tungsten Alloy | WuNiFe alloy,Carbide Wolfram...... | |||||||

The Blanks | stamping parts,forging parts,die casting parts,profile,extrusion...... | |||||||

The plastic | PP,PE,PU,PC,POM,PTFE,Acrylic,ABS,Delrin...... | |||||||

All the materials are with the material quality certificate, we are familiar with the international material norm and the material substitute grade! | ||||||||

Q: What are our advantage?

A: 1.Price: Factory competitive price;

2.Service: R&D,OEM & ODM;3.Quality: ISO-9001,100% QC inspection before packing,0 defects;

4.Factory delivery: 7-25 days.

If you want to get much more information regarding motorcycle parts, you please feel free to contact with us as following at any time,we are 24 hours online!

Похожие товары

Sus304 бесшовная труба из нержавеющей стали, труба Asme b36.10 м, размер 3 дюймов, 7,5 дюймов, A213, 309, 310, 321, 347, 347 ч

301 302 304 316 Овальная труба 904L из нержавеющей стали

хорошее качество 301 310 304 круглый стальной трубы трубы сварные

Китайский производитель AISI 201 202 304 316 Ss бесшовная круглая труба из нержавеющей стали

Заводская цена, AISI ASTM A269 TP SS 310S 2205 2507 C276 201 304L 321 316 316L 304 прямоугольная квадратная труба из нержавеющей стали

Горячекатаный Ss201/202/304/304L/316/316L/420 обработка поверхности Hl/Ba/Sb/Ba/2b ASTM/AISI/DIN шестиугольная труба/труба из нержавеющей стали

Высокое качество Хорошая цена, большой диаметр 301 трубки из нержавеющей стали

Новые поступления

Новинки товаров от производителей по оптовым ценам