Прошедшее ISO 9001 полностью автоматическое оборудование для производства труб HF Erw

- Категория: >>>

- Поставщик: Taiyuan Huaye Equipment Research Institute (Co. Ltd.)

Сохранить в закладки 60486417867:

Описание и отзывы

Характеристики

Passed ISO 9001 fully automatic HF Erw Pipe Mill Making Equipment

Passed ISO 9001 fully automatic HF Erw Pipe Mill Making Equipment

Technical Specification

Model | Specification(mm) | Thickness(mm) | Coil Weight | Speed(m/min) | Capacity | Area (Estimater M) |

LG-100 | Φ25~Φ114 | 3~8 | 5 | 30~60 | ~1100 | 12×100 |

LG-160 | Φ60~Φ165 | 3~10 | 10 | 20~40 | ~1600 | 12×100 |

LG-200 | Φ114~Φ219 | 4~12 | 15 | 10~30 | ~1800 | 15×150 |

LG-300 | Φ165~Φ325 | 4~14 | 20 | 8~25 | ~3000 | 18×180 |

LG-350 | Φ165~Φ355 | 4~14 | 20 | 8~25 | ~3500 | 18×180 |

LG-400 | Φ219~Φ406 | 4~16 | 30 | 8~20 | ~4000 | 21×180 |

LG-500 | Φ219~Φ508 | 4~16 | 30 | 8~20 | ~4500 | 21×260 |

LG-600 | Φ219~Φ610 | 4~20 | 30 | 8~20 | ~5000 | 24×280 |

More Pictures Show

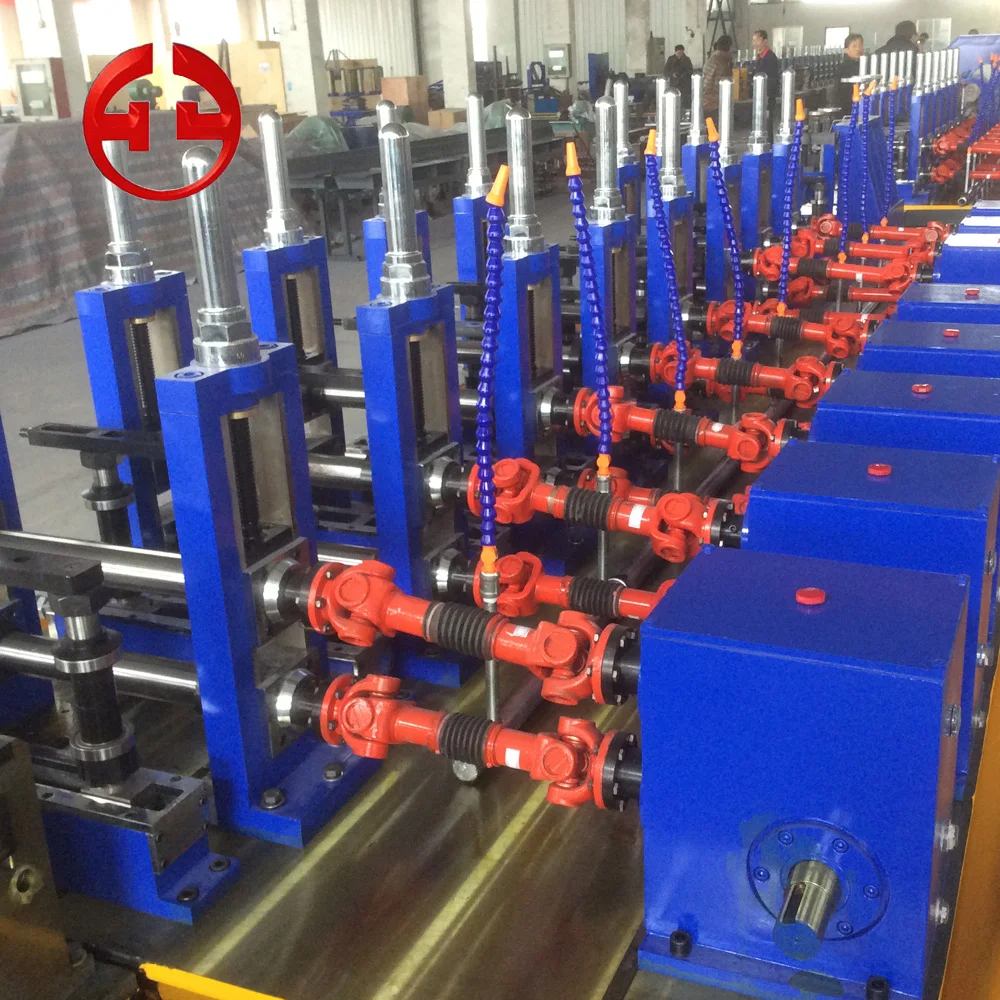

1.Brief introduction of ERW tube mill & pipe mill

- The ERW tube mill & pipe mill is a series of machines that builds longitudinal weld seam tubes and pipes with steel strips of certain width.

- It starts by uncoil and flatten the slitted steel coils into steel strips.

- The flattened steel strips will then be inserted into the forming machine and the roller tolling in the machine will roll the strip to round pipe shape.

- The rolled strips will then be sent into the weld box where the tube is welded by a high frequency solid state welder.

- The welded tubes will be formed to expected shape or size in a sizing machine. Finally the tubes will be cut to length and bundled.

2. Function

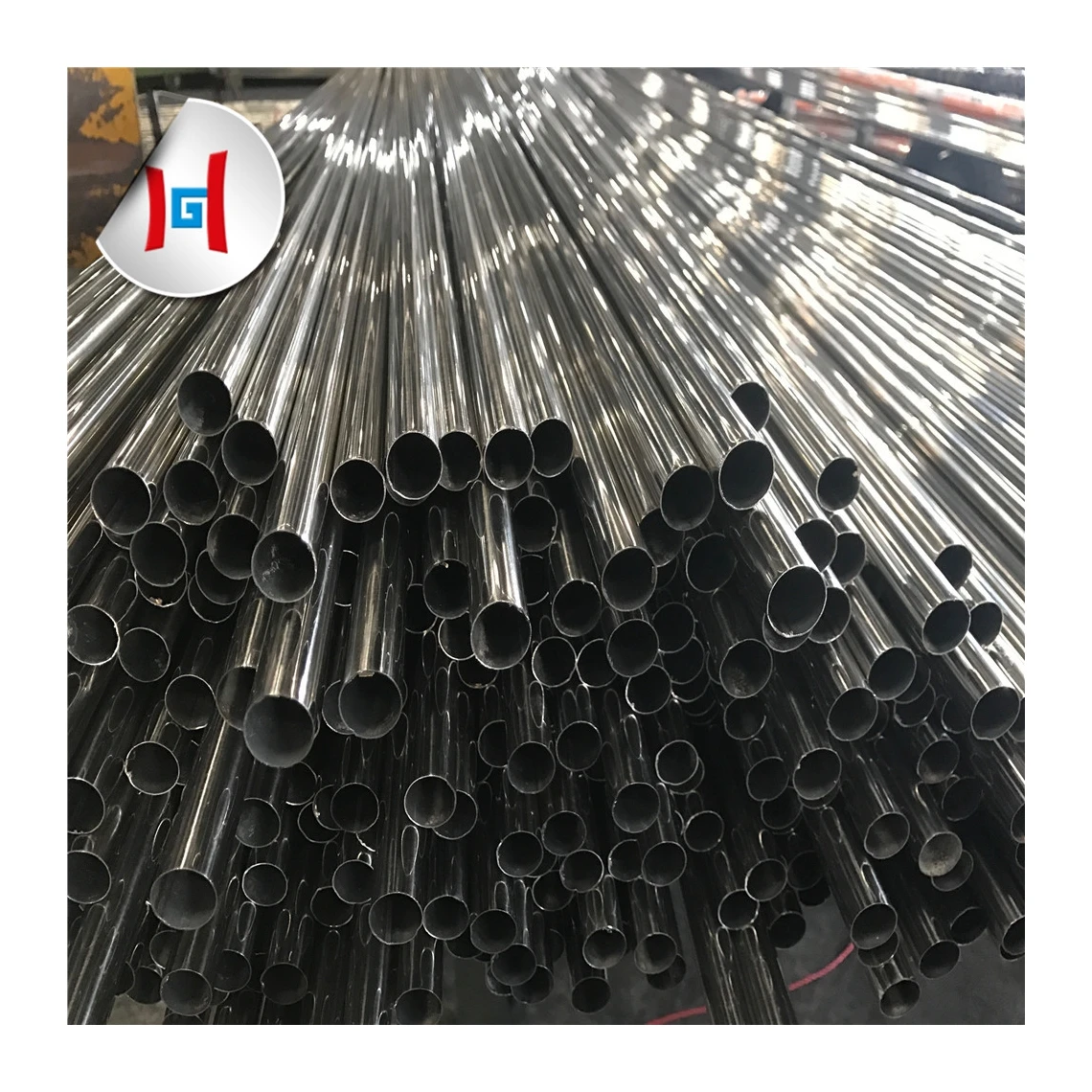

This pipe is used especially for Petroleum, Natural gas, City gas, Pipe network, Chemical industry, Electricity, Steel truss, Water and Gas pipeline; it is widely used for a variety of pressure

3.Process flow

Feed - uncoil - straighten - shear and buttweld - loop storage - form - HF welder - IF anneal - cool - size -cut - output - end bevel - hydraulic test - collect .

4. Machine parts in the working line

(1) Uncoiler

(2) Hoop cage or Horizontal Accumulator

(3) Main Machine:

- Forming Machine

- Roller System of Forming

- Seam Guide

- High Frequency Induction Welding Machine

- Roller System for Moving

- Burr Removing Frame (Inside and outside Burr )

- Water Cooling System

- Sizing Machine

- Roller System of Leveling

- Speed Testing Wheel

- Turkish Frame

- Auto Flying Saw Controlled by Computer

- Run out table

- Electric Control Equipmen

- High Frequency Welding Machine

Похожие товары

Бесшовная труба из нержавеющей стали по цене мельницы

Спойлер для Subaru XV 2012-2017 XV, спойлер без света из АБС-пластика, цветной задний спойлер для крыла автомобиля

Astm a106 grb бесшовные трубы из углеродистой стали трубы впв трубопрокатного стана

99% чистый октамолибдат аммония по низкой цене CAS 12411-64-2

Бесплатные образцы, фторид алюминия для электролитических алюминиевых производственных пакетов, белый, CAS HEN, промышленное хранение, классная упаковочная пленка

Китай, бренд Feiyuan, бифторид аммония

Малый диаметр 10,5 мм Яркий черный отжиг erw круглая стальная труба/тонкая стена прямой шов сварная стальная труба

Новые поступления

Новинки товаров от производителей по оптовым ценам