Автоматический Дозирующий станок для клея на солнечной

- Категория: >>>

- Поставщик: Guangzhou Zhengqi Technology Co. Ltd.

Сохранить в закладки 60535261507:

Описание и отзывы

Характеристики

auto glue dispensing machine in solar panel assembly line

Two Components Glue Dispenser Machine PGB-700/PGB-1200/PGB-1500

Model: PGB-700/PGB-1200/PGB-1500

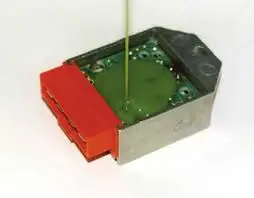

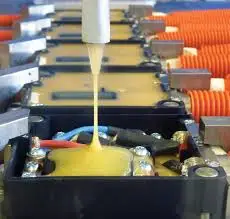

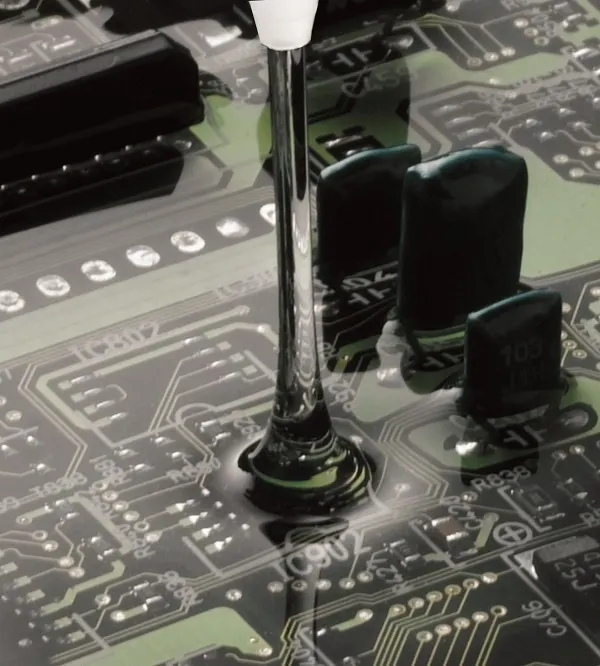

Applications:Capacitor, Power Supply, Transformer, Ignition Coil, Reverse Sensor, Circuit Board, Electronic Ballast , Other Electronic Products Where Glue Potting Demanded.

Application Areas:

1. Electrical Products: Microsensors, sensors,automotive parts ,ignition coil , electronic parts, integrated circuits, circuit board solder paste, fixed and dust and moisture protection, LCD liquid crystal screen, speakers, headphone, audio, LED, optical lens, SMD transformers, relays.

2. Communication Products: Communication boxes , Keypad, mobile phone casing bonding, radio, telephone, Computers, MP4, electronic toys, chassis bonding, switches, connectors, plug cable.

Suitable Materials:

Epoxies , Urethane(PU) or Silicone .

Two components glue, AB glue, AB part glue, silicone, epoxy resin, polyurethane;

All kinds of two-component mixed glues with required ratio, such as epoxy resin AB glue, polyurethane, silica gel, PU glue, flocking glue, paint, etc.

Artificial glue potting VS Intelligent glue potting :

The problems of potting by manual:

1. Artificial glue potting completely rely on manual operation, it is easy cause the proportion deviation and uneven mixing .

2. Manual mode waste of glue is very serious and it is difficult to control the flow of the product manually. The glue will be waste much on different containers like buckets, and the bucket that sticks to glue is not easy to clean that increase a lot of filling glue bucket to wait for consumable material.

3. The consistency of products is poor, and there are many uncontrollable factors in the production process, such as poor glue dispensing, inaccurate amount of glue dispensing, easy manual fouling of products, uncontrollable quality of each batch of products, consistency, defective products, too much waste and increasing costs.

4. Manual glue filling is slow and expensive for labor cost, consumables and cleaning agents.

5. It is difficult to manage, labor is expensive, flexibility is not strong, recruitment is difficult, and output cannot be guaranteed.

The advantages of using intelligent dispensing machine for potting :

1. Fully automatic operation, accurate proportion and even mixing

2. Glue dosing while mixing, no waste of glue and no waste of consumables. Precise dosing and dispensing.

3. The glue amount of the product is consistent and good. The edge of the machine is clean without glue.

4. Machine glue dosing save much time and effective and lower cost

5. There is no need for glue pouring staff, only one operator is needed to complete the mass production

Machine Tech Data :

Model No: | PGB-700 |

Mixing Ratio | 100:100-10:100(1:1-1:10) Adjustable |

Metering precision | ±1% |

Outflow speed | 1g/sec-12g/sec |

Mixing precision | ±1% |

Mixing mode | Dynamic mixing /Static mixing |

Glue Viscosity | Lower than 35000 CPS (mPa·s) |

Control mode | PLC + Touch Screen |

Control system | Independent R&D |

Measuring mode | Stepping motor/High-precision, wear-resistant, long-life Gear pump |

Working voltage | AC 220V 50Hz/60Hz |

Power requirement | 3.55KW |

Machine Dimension | 1500(L)*1200(W)*1500(H)mm |

Weight | 460 KG Roughly |

Work environment | Humidity: 20%~98%RH; Temperature: 0~+40°c |

Model No: | PGB-1200 |

Working area | 1200x1200x80mm |

Mixing Ratio | 100:100-10:100(1:1-1:10) Adjustable |

Metering precision | ±1% |

Outflow speed | 1g/sec-12g/sec |

Mixing precision | ±1% |

Mixing mode | Dynamic mixing /Static mixing |

Glue Viscosity | Lower than 35000 CPS (mPa·s) |

Control mode | PLC + Touch Screen |

Control system | Independent R&D |

Measuring mode | Stepping motor/High-precision, wear-resistant, long-life Gear pump |

Working voltage | AC 220V 50Hz/60Hz |

Power requirement | 3.55KW |

Machine Dimension | 11960(L)*1550(W)*1327(H)mm |

Weight | 600 KG Roughly |

Work environment | Humidity: 20%~98%RH; Temperature: 0~+40°c |

Model No: | PGB-1500 |

Working area | 1500x480x80mm |

Mixing Ratio | 100:100-10:100(1:1-1:10) Adjustable |

Metering precision | ±1% |

Outflow speed | 1g/sec-12g/sec |

Mixing precision | ±1% |

Mixing mode | Dynamic mixing /Static mixing |

Glue Viscosity | Lower than 35000 CPS (mPa·s) |

Control mode | PLC + Touch Screen |

Control system | Independent R&D |

Measuring mode | Stepping motor/High-precision, wear-resistant, long-life Gear pump |

Working voltage | AC 220V 50Hz/60Hz |

Power requirement | 3.55KW |

Machine Dimension | 11960(L)*480(W)*1231(H)mm |

Weight | 600 KG Roughly |

Work environment | Humidity: 20%~98%RH; Temperature: 0~+40°c |

Features:

1. Automatic metering and mixing, touch screen PLC control system, English operation interface allow easy to set parameters;

2. Big LCD screen displays various processing data;

3. Easy programming of dots, stripes, arcs, compound arcs and patterns on different planes;

4. Gluing speed and timing can be set;

5. CAD file can be imported and turned to be dispensing patterns, and downloaded via USB; (optional function)

6. Mixing ratio 1:1-1:10 and gluing volume can be set and adjusted as per actual need. Dynamic mixing ensure two component glue to be mixed to a fully homogeneous consistency;

7. Metering, mixing and gluing simultaneously;

8. Two tanks keep A glue and B glue separately;

9. Liquid level sensor, alarm function;

10. Tank stirring and vacuum defoaming function optional;

11. Auto cleaning; The cleaning mode can be manually or automatically, manual mode just remove the mixing tube then soak into cleaning agent, after 10 min take out and clean with compressed air, Automatic mode only need to operate the cleaning switch on touch screen within 1 minute to complete;

12. Glue tank/metering pump/glue pipe heating function (optional);

13. Vacuum control keeps thin fluids from dripping;

14. Unique control system which will not influenced by air pressure factor, ensures optimal dispensing performance;

15. XYZ axis can be programmed to dispense glue along desired patterns.

Machine description and working principle

PGB-700 system accurately meters, mixers and dispenses two components medium to low viscosity materials for potting gasketing, sealing, encapsulation and syringe filling. The system ratio form 1:1 t0 10:1.

The system is composed of material tank, metering pump, metering motor, material pipe, two component valves, motor for dynamic stirring, mixing tube and 3 axis robotic arms.

Two kinds of glue are separated before they mix in mixing tube, so the glue will not cure in devices. Glue valve is with vacuum function to keep thin fluid from dripping. Other optional functions include:

Tank stirring function;

Tank defoaming function;

Thermostat heating function on Tank, pipe, and valve;

Advantage of automatic glue dispensing machine:

Dispensing robots automate most fluid assembly processes ensuring fast and repeatable deposits without mess, waste or error. For making repeat dots, beads, arcs and circles with any fluid, adhesive or paste. Easy to setup and run and these systems are supplied complete.

Glue

Похожие товары

Специальная обработка PU ремень ГРМ черного цвета HTD5M с индивидуальным зеленым узором ПВХ покрытием

Рождественские канцелярские подарочные наборы

MAX-730C OTDR iolm EXFO 1310/1550/1650/1625nm установки и устранение неисправностей PON/метро FTTh

Сделано в Китае, высококачественные Брызговики, задние Автомобильные Брызговики для NISSAN (DONGFENG)

Заводской металлический кобальтовый лом 99.98%/кобальтовый по лучшей

Одноразовая бутылка для сока и напитков с металлической серебряной крышкой, 500 мл, 650 мл

CXA2170Q электронных компонентов совершенно новый аппарат не Привязанный к оператору сотовой связи IC в

Новые поступления

Новинки товаров от производителей по оптовым ценам