«Интеллектуальная машина для нанесения маски лица/накладок на

- Категория: Other Home Product Making Machinery >>>

- Поставщик: Jiangsu Atong Machinery Manufacturing Co. Ltd.

Сохранить в закладки 60553772698:

Описание и отзывы

Характеристики

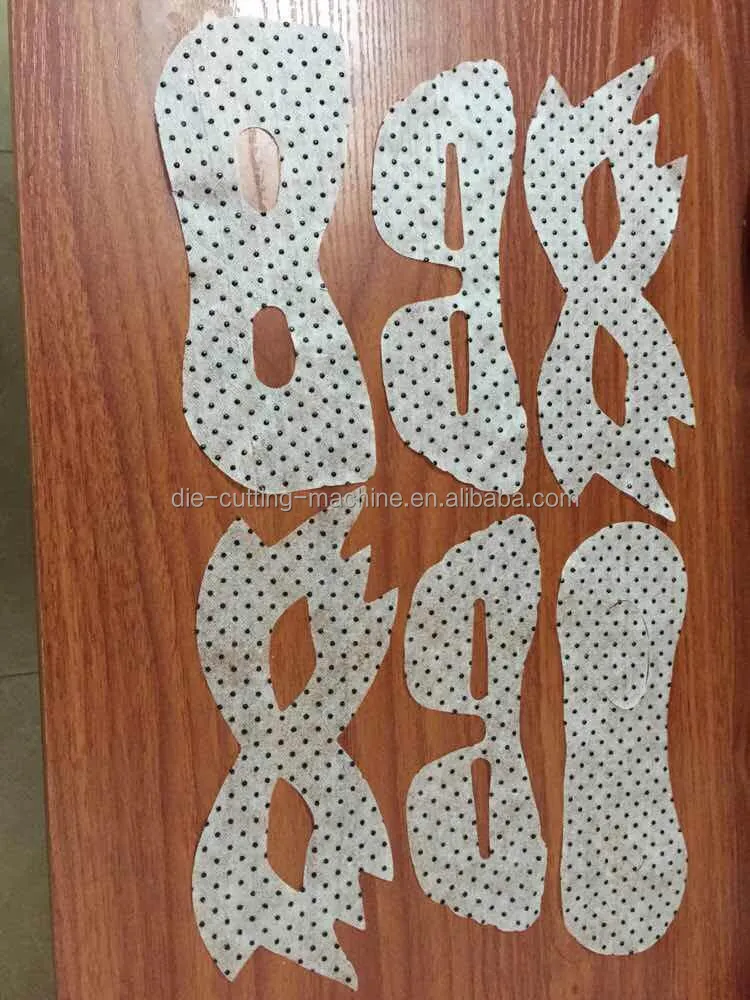

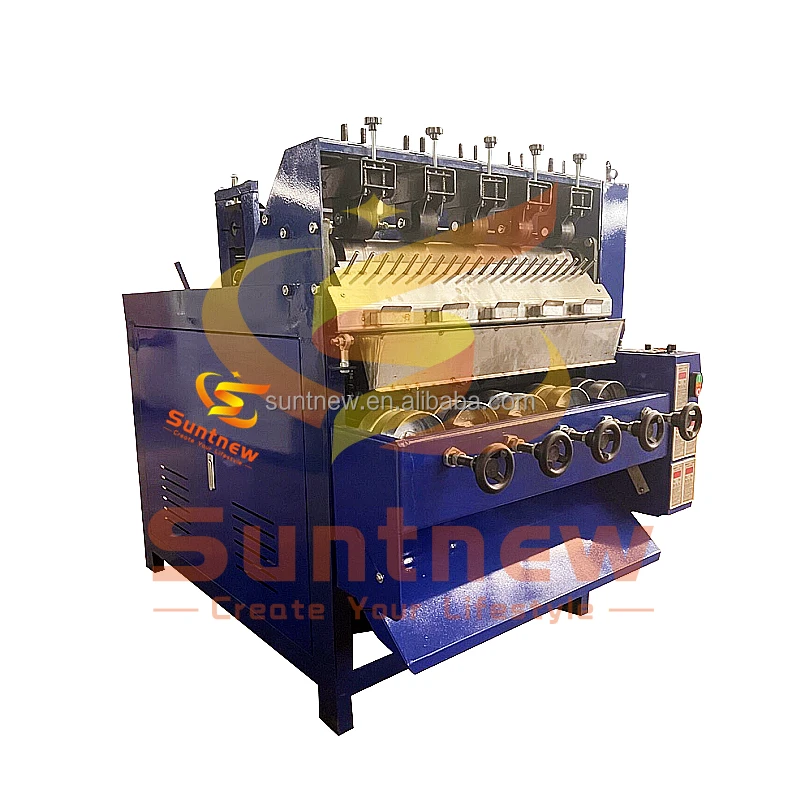

This machine is applicable for full-automatic die-cutting of facial mask. With the CAD full-automatic trepanning and layout system, it can achieve work efficiency of 6 traditional common processing units and save at least 8% raw materials, thus reducing labor cost significantly. Its output in one shift reaches as high as 0.8-1 million pieces, with high rate of finished products. Its technical performance is assessed international advanced level, enabling to replace imported goods.

| \t | \t | \t | \t |

| \t | \t | \t | \t |

| \t | \t | \t | \t |

| \t | \t | \t | \t |

1. Double oil cylinder and precise four-column automatic balancing double-link mechanism to ensure that the depth of each cutting point accuracy ± 0.05mm.

2. cutting head in contact under pressure cutter 10mm automatic retarder before, so when cutting layers of material, the uppermost and lowermost no size error.

3. The balance due to cutting precision, can greatly reduce the loss of the cutter and cutting board cutting edge of better, more can reduce the cutting board consumption.

4. HMI .plc programmable control, servo motor automatic feed mechanism.

5. Servo motor control feeding so that the positioning accuracy ± 0.1mm.

6. The servo motor automatic feeding mechanism, improve work efficiency by 80%.

7. unique setting structure with the cutter and cutting height. Stroke adjustment simple. Accurate.

8. Central automatic lubrication system ensures machine precision and enhance machine durability.

9. Hydraulic system: double cylinders simultaneously, reservoir storage device oil filter device.

10. The delivery portion by Japan's Mitsubishi PLC control, servo motor drive material from the machine side input, after die-cutting, from the other side of the output to ensure accurate feeding, stable operation; and feeding length can be convenient touch screen adjustment, fault display information to facilitate machine maintenance.

11. The servo motor control feeding with cylinder clamping device.

12.CAD automatic typesetting, cutting die according to the specifications and materials, automatic alignment, intelligent, efficient, material saving.

NOTE: cutting area: adopt ordinary cold steel welding die cutter. Adopt laser wood die cutter. Made to order for special specifications.

Jiangsu A Tong Machinery Manufacturing Co.,Ltd.is our country engaged in shoe-making machinery, leather machinery, bags and other precision machinery and general machinery series product research and development production scale of the enterprise. The company is located in the famous "China shoes city" state-level spark technology concentration areas, Yan cheng city ,Jiangsu province, industrial park. Company technical force is abundant, the production testing facilities, beautiful environment, convenient traffic. The company has been rated as "private technology enterprises in Jiangsu province", "shoes machine chamber of commerce member enterprise in Jiangsu province", "heavy contract, keep promise" enterprise.

1.Q:Are you a factory or trading company?

A: we are a factory. welcomed to visit us .

2.Q:Where is your company?How I can visit it?

A:Our company is located in dagang Town,Yandu District,Yancheng city,Jiangsu Province.

It just needs 4 hours from Shanghai.

3.Q: Where is your Loading Port ?

A: Shanghai. port,China.

4.Q:What is your delivery time?

A:It depends on your order quantity,if just few sets,it needs 5-20 days.

5.Q:Could we use our own brand name?

A:Yes.

6.Q:What is the material of your products?

A:Steel,cast iron and so on.

We can also choose the materials as customers'needs.

7.Q:What are your payment terms?

A:30% deposit and balance before shipment.

Why Choose Us ?

1. Low MOQ: It can meet your promotional business very well.

2. OEM Accepted : We can produce any your design .

3. Good Service : We treat clients as friend.

4. Good Quality :We have strict quality control system .Good reputation in the market.

5. Fast & Cheap Delivery: We have big discount from forwarder (Long Contract).

6. Discount: Purchased the machine in our company, the machine parts are the discount.

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Servic

* Training how to instal the machine, training howt o use the machine.

* Engineers available to service machinery oversea

Package Detail: Wooden case

Shipping Details:Usually by sea

Delivery Time:30 working days after order confirmed

Die cutting press export standard wooden cases, which is suitable for long-distance sea transportation and various types of weather conditions. A full set of maintenance and operation manuals is included.

Похожие товары

Профессиональная простая в использовании 600 шт./мин машина для производства ватных тампонов

Машина для очистки сетки автоматическая машина производства оцинкованной/медной

best selling medical cotton stickers making production

Машинка для изготовления шляп, носков, машинка для изготовления зимних шляп, вязальные машины

Машина для изготовления кухонных мочалок из нержавеющей стали ss 410

Промышленный резервуар для Смешивания Жидкого мыла из нержавеющей стали с платформой

Полностью автоматическая машина для изготовления вешалки одежды с функцией сварки из

Новые поступления

Новинки товаров от производителей по оптовым ценам