B1W069 Ag Cu Zn Cd паяльный стержень серебряный припой с кадмием

- Категория: >>>

- Поставщик: Yantai Tibright Welding Materials Co. Ltd.

Сохранить в закладки 60556429041:

Описание и отзывы

Характеристики

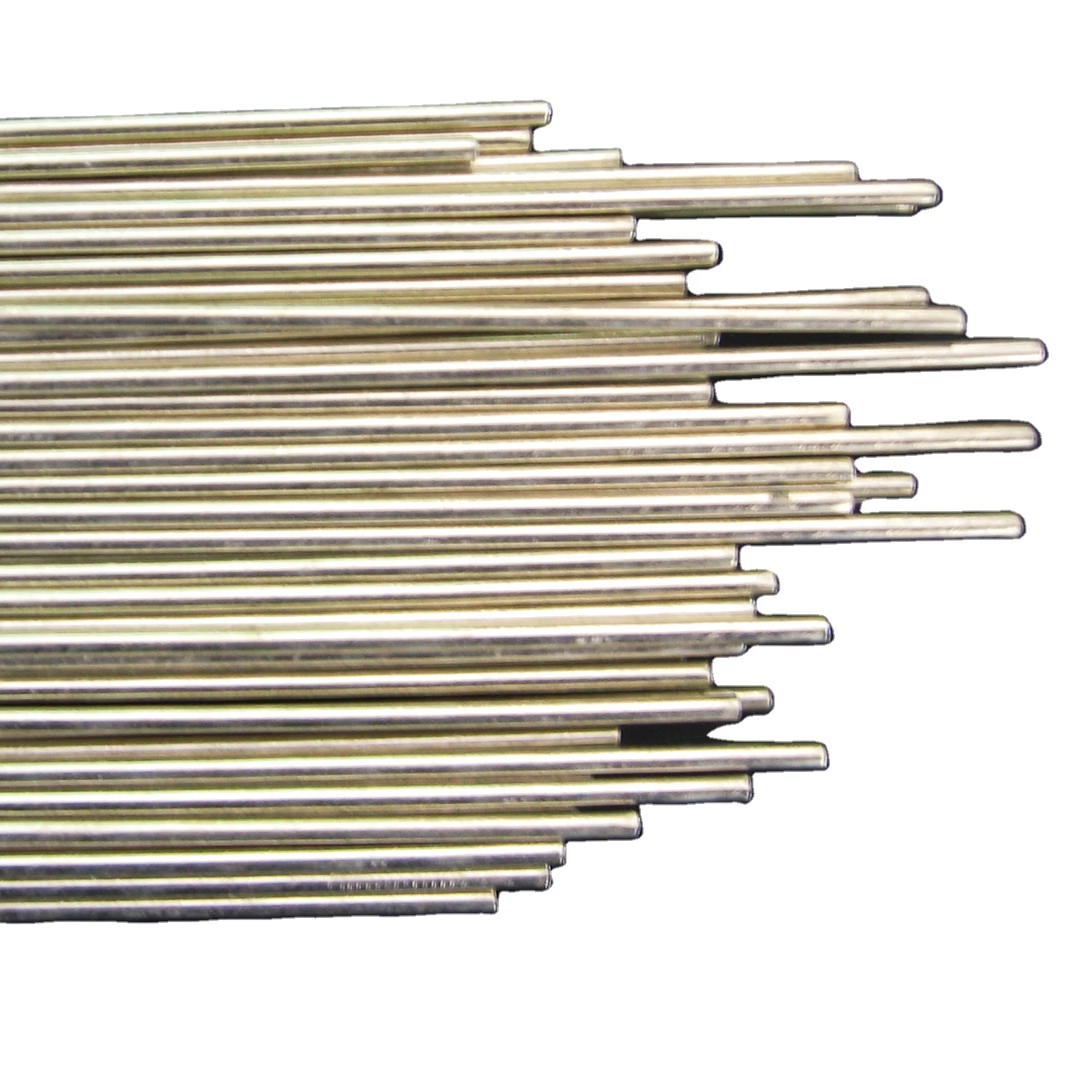

B1W069 Ag-Cu-Zn-Cd Brazing Alloy Rod

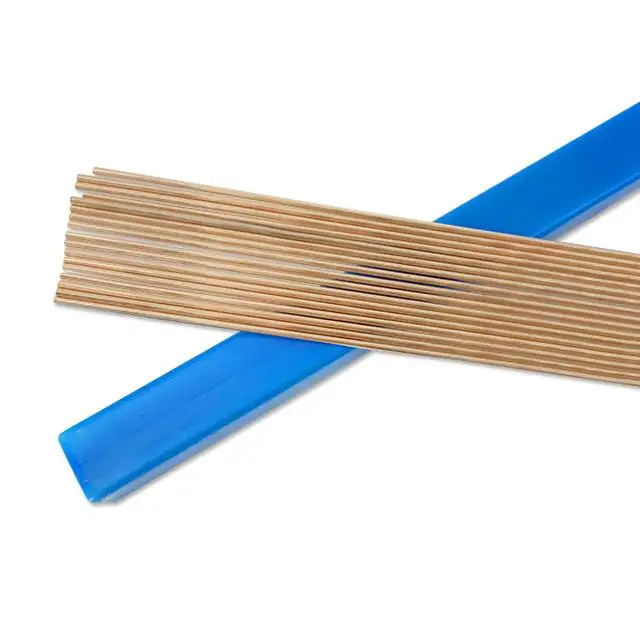

Silver alloy brazing filler metal is a very widely used brazing filler metal. It is used to braze copper, steel, stainless steel, diamond, carbide alloys etc. Two main kinds are silver copper zinc alloy and silver copper phosphorous alloy. There are also silver copper, silver copper nickel alloys. It can be crafted to many forms, such as, rod, wire, ring, sheet, powder, paste, etc. This is a very widely used filler metal, especially in the industries of refrigerator, instruments, valve, glasses, tools, etc.

Silver alloy brazing filler metal usually is used together with silver brazing flux.

There are several types of silver brazing alloys varieties according to the materials, for example, Ag-Cu, Ag-Cu-Zn, Ag-Cu-Zn-Sn, Ag-Cu-P, Ag-Cu-Zn-Mn, and so on. Customers chose different type and compostion based on the different utility purposes.

Silver Alloy Brazing Filler Metal | ||||||||||

Classification | Chemical composition | Critical points℃ | Density g/cm3 | Standard AWS A 5.8 | Costom Grades | |||||

Ag | Cu | Zn | Sn | Other Elements | Solidus | Liquidus | ||||

BAg20CuZn | 20 | 44 | 36 | <1 | 690 | 810 | 8.7 | |||

BAg25CuZn | 25 | 40 | 35 | <1 | 690 | 800 | 8.8 | HL302 | ||

BAg30CuZn | 30 | 38 | 32 | <1 | 690 | 760 | 8.9 | BAg-20 | ||

BAg30CuZnSn | 30 | 36 | 32 | 2 | <1 | 650 | 750 | 8.8 | ||

BAg35CuZn | 35 | 32 | 33 | <1 | 680 | 730 | 9 | BAg-35 | ||

BAg38CuZnSn | 38 | 31 | 29 | 2 | <1 | 660 | 720 | 9.1 | BAg-34 | |

BAg40CuZn | 40 | 30 | 30 | <1 | 660 | 720 | 9.1 | |||

BAg40CuZnSn | 40 | 30 | 28 | 2 | <1 | 640 | 700 | 9.1 | BAg-28 | |

BAg45CuZn | 45 | 30 | 25 | <1 | 677 | 743 | 9.1 | BAg-5 | HL303 | |

BAg45CuZnSn | 45 | 27 | 25 | 3 | <1 | 646 | 685 | 9.2 | BAg-36 | |

BAg50CuZn | 50 | 34 | 16 | <1 | 688 | 774 | 9.5 | BAg-6 | HL304 | |

BAg56CuZnSn | 56 | 22 | 17 | 5 | <1 | 620 | 650 | 9.4 | BAg-7 | |

BAg60CuZn | 60 | 26 | 14 | <1 | 695 | 730 | 9.5 | |||

Silver Alloy brazing filler metal with cadmium has special advantages such as high wettability, high fluidity, low melting point. However, because of the toxicity of cadmium, the working environment should be well ventilated and shielded during the brazing process.

Silver Alloy Brazing Filler Metal With Cadmium | ||||||||||

Classification | Chemical composition | Critical points℃ | Density g/cm3 | Standard AWS A 5.8 | Costom Grades | |||||

Ag | Cu | Zn | Cd | Other Elements | Solidus | Liquidus | ||||

BAg20Cd | 20 | 40 | 25 | 15 | <1 | 620 | 750 | 8.7 | ||

BAg25Cd | 25 | 30 | 27.5 | 17.5 | <1 | 605 | 710 | 8.8 | BAg-33 | |

BAg30Cd | 30 | 28 | 21 | 21 | <1 | 610 | 690 | 9.1 | BAg-2a | |

BAg34Cd | 34 | 22 | 24 | 20 | <1 | 610 | 670 | 9.1 | BAg-2 | |

BAg40Cd | 40 | 19 | 21 | 20 | <1 | 595 | 630 | 9.3 | HL312 | |

BAg45Cd | 45 | 15 | 16 | 24 | <1 | 605 | 630 | 9.4 | BAg-1 | |

BAg50Cd | 50 | 15 | 16 | 19 | <1 | 620 | 640 | 9.5 | BAg-1a | |

Silver-phosphorous alloy brazing filler metal has high wettability, low melting point. In certain applications, it can replace high silver composition brazing materials.

Copper Phosphorus Alloy Brazing Filler Metal | |||||||||

Classification | Chemical composition | Critical points℃ | Density g/cm3 | Standard AWS A 5.8 | Costom Grades | ||||

Ag | Cu | P | Other Elements | Solidus | Liquiduss | ||||

BCu91AgP | 2 | 91 | 7 | <1 | 643 | 788 | 8.1 | BCuP-6 | HL209 |

BCu88AgP | 5 | 88 | 7 | <1 | 650 | 780 | 8.2 | BCuP-7 | HL207 |

BCu89AgP | 5 | 89 | 6 | <1 | 650 | 810 | 8.2 | BCuP-3 | HL205 |

BCu87AgP | 6 | 88 | 7 | <1 | 650 | 740 | 8.3 | BCuP-4 | |

BCu84AgP | 10 | 84 | 6 | <1 | 650 | 750 | 8.3 | ||

BCu80AgP | 15 | 80 | 5 | <1 | 650 | 800 | 8.4 | BCuP-5 | HL204 |

Normal packaging:

Other packing can be customized according to customer's requirement

| Product | Dimension | Packing |

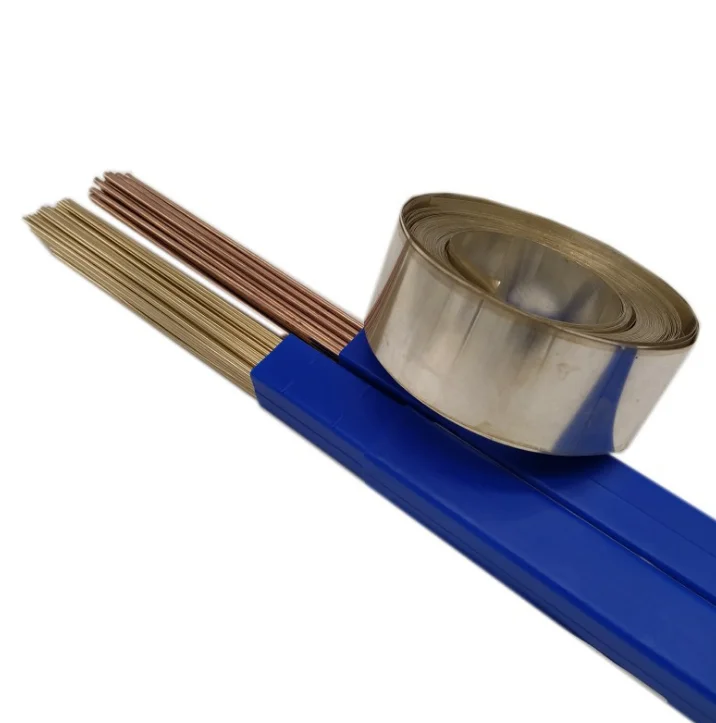

| Brazing Alloy Rod | 500 mm | 1 kg/bag, 20 kg/box,10 kg/bag |

| Brazing Alloy Rod | 1000 mm | 5 kg/bag, 30 kg/box |

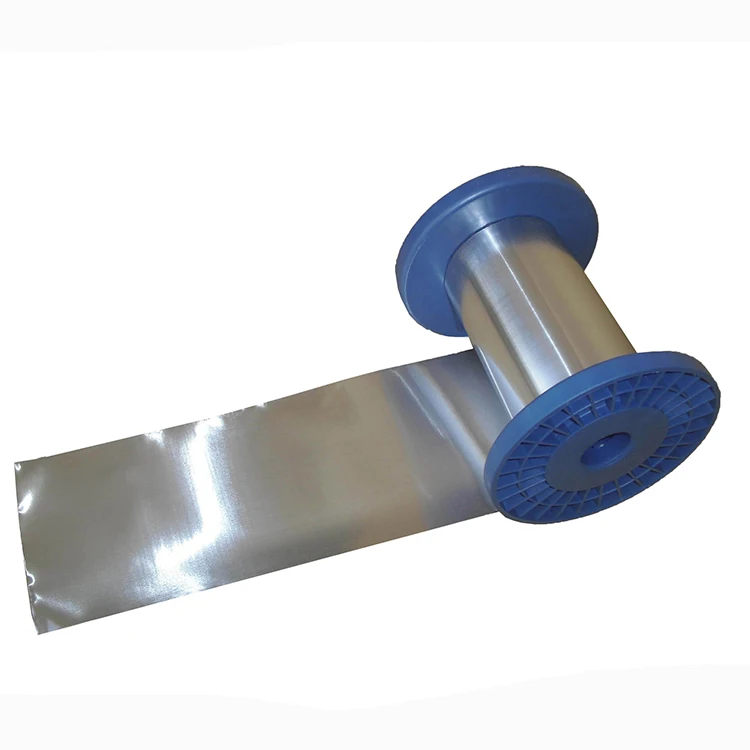

| Brazing Alloy Wire | Roll | 5 kg/roll, 10 kg/roll, 20 kg/roll |

| Brazing Alloy Sheet/Strip | All kinds | 1 kg/bag, 10 kg/box, 20 kg/box |

| Brazing Alloy Ring | All kinds | 1 kg/bag, 10 kg/box, 30 kg/box |

| Brazing Alloy Powder | 5 kg/bag, 10 kg/box, 30 kg/barrel | |

| Brazing Alloy Paste | 1 kg/can, 10 kg/barrel, 30 kg/barrel | |

| Brazing Flux Powder | 500 g/can, 500 g/bag, 20 kg/box | |

| Brazing Flux Paste | 1 kg/can, 1 kg/bag, 40kg/box | |

| Brazing Flux Paste-Auto | 1 kg/can, 1.5 kg/can, 9kg/box | |

| Brazing Flux-liqui/gas | 3 liter/barrel, 3.5 kg/barrel, 12kg/box, 200 liter/barrel |

With hundreds of products in our product library, TiBright is a professional developer and international supplier of inclusive brazing materials, equipment, and consultant.

One highlight of our services is that we provide customized products specially designed for specific customers. We have a lot of successful cases in which the customers had the products suitable for their own procedures, environment and operation routines perfectly.

We also provide entire brazing solution for customers to solve all the problems related to brazing process. We provide consultant for customers with complicated applications and innovative demand.

About sixty percent of our equipment and devices are designed and crafted in our own machine workshop, which engaged us the ability of prompt reaction towards new updates from customers. We also produce specially designed brazing tools and machines. We often develop products together with our customers for their individual needs.

Yantai TiBright Welding Materials Co. Ltd. was started from a laboratory in 1996 and founded in 2000. The company is the first one who specialized in brazing materials in China. The pioneers of the company started product formulas from very basic research.

Since 2010, our research team has been focusing on the brazing alloy powder and paste as well as the self-fluxing alloys, such as flux coated wires and rings, flux cored wires and rings.

In the year 2015, TiBright was asked to be the first draftsman of the industry standard of China "JB 6045-2015, Fluxes for Brazing" and attended the drafting work of many standards as expertise. TiBright’s research team members apply for patents and publish research articles on academia periodicals every year. By 2016, TiBright has been authorized 15 patents.

Our main current customers are in dozens of different industries, such as radiator, compressor, air conditioner, refrigerator, electric, eye glasses, auto parts, cutting tools, kitchen and bathing, medical instruments, nuclear station, and so on. Our famous customers include Haier, Gree, Media, Siemens, Sanhua, and so on.

Похожие товары

Фабрика обеспечивает 0,6/0,8/1/1.2/1.5 мм sn bi припойная проволока рулон

Серебряный паяльный стержень Coper/серебряный сварочный стержень/серебряный паяльник

Заводская Прямая цена, высокое качество, оптовая продажа, серебряная паяльная проволока, латунный сварочный стержень

95Sn/5Sb 96.5Sn/3.5Ag паяльники 96,5 олова/3,5 серебра и 95 олова/5 антимоний

Высококачественная Серебряная паяльная паста SAC0307 без свинца Sn99Ag0.3Cu0.7, паяльная паста из сплава Sn-Ag, не защищает окружающую среду

Паяльная проволока с сердечником из серебра 5% пробы для кондиционера и холодильника, 1,27 мм x 3,2 мм x 500 мм

Оловянно-свинцовый сварочный материал Sn60Pb40, Оловянная паяльная проволока

Новые поступления

Новинки товаров от производителей по оптовым ценам