Низкая цена прочный пластилизатор и линия упаковочной машины

- Категория: >>>

- Поставщик: Shanghai Fhope Machinery Co. Ltd.

Сохранить в закладки 60562281763:

Описание и отзывы

Характеристики

Bottom price durable palletizer and wrapping machine line

Description of palletizer and wrapping machine line:

| \t | \t | \t | \t |

| \t | \t | \t | \t |

| \t | \t | \t | \t |

| \t | \t | \t | \t |

| \t | \t | \t | \t |

| \t | \t | \t | \t |

| \t | \t | \t | \t |

| \t | \t | \t | \t |

| \t | \t | \t | \t |

| \t | \t | \t | \t |

| \t | \t | \t | \t |

| \t | \t | \t | \t |

| \t | \t | \t | \t |

| \t | \t | \t | \t |

| \t | \t | \t | \t |

Technical Data

?\ta. Construction: Heavy duty, welded.

?\tb. Wrapping method: Bottom, middle and top wrapping layer can be set from 0-99 winds.

? c.\tTurntable speed can be adjusted by inverter.

?\td. Film carriage speed can be adjusted by inverter.

?\te. Wrap settings: Re-wrap function, overwrap and overlap adjustment

?\tf. Wrap counters: Independent top and bottom.

?\tg. Emergency stop: Red mushroom head.

?\th. Turntable plate thickness: 10mm is much more rigid to anti-deformation when load heavy goods.

?\ti. Easy for operation and daily maintenance.

?\tj. Manual operation, flexible & economical.

?\tk. Customized extended height and turntable size are available.

?\tl. Can equipped with pneumatic top press, pre-stretch and access ramp according to needs.

Main option parts

1. 1000mm Prestretch Carriage for wider stretch film.

2. Extended Wrap Height Capacity up to 3000mm.

3. Extended load diagonal for larger pallet sizes.

4. Automatic End of Cycle Film Cut-Off.

5. Press down device and ramp

6. Many other options are available...

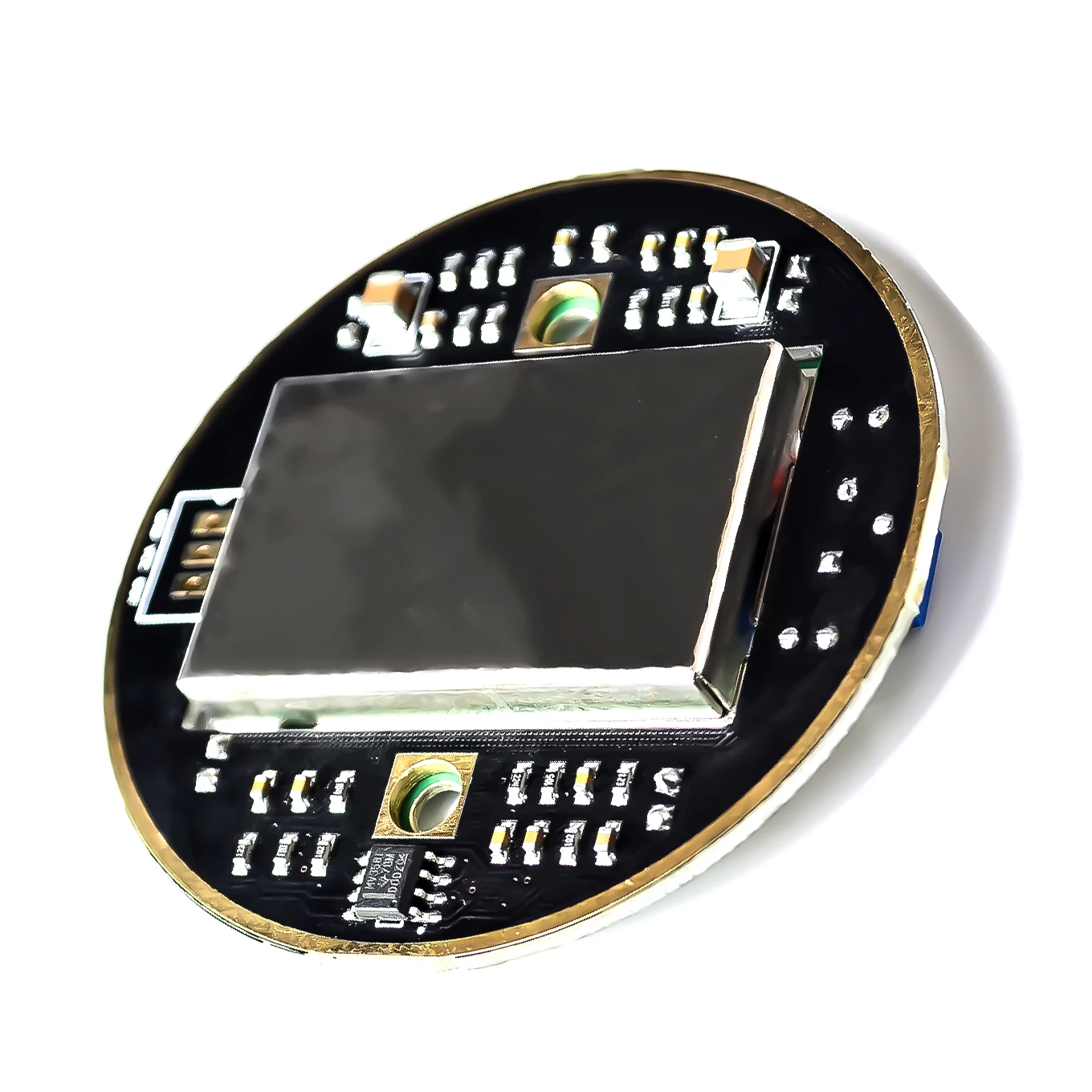

Detailed Images of palletizer and wrapping machine line

Our Most Popular Rotary Arm Stretch Wrapper - Floor Mounted Frame

The most popular durable stretch wrap machine for all pallet packaging requirements, can be Custom Engineered to meet specific applications. 2200kg Load Weight Capacity, 15 RPM Stretch Wrapping Speed. Fully Loaded control features for maximum flexibility.

Easy operation 3 STEP "EASY THREAD" film Loading Ensures Safety

Re-loading the Film roll on any carriage is not an easy task with many machines. With our “Easy Thread” access design, we make it simple and safer.Simply unlatch and open the access door, pull film tail past open access door and close the door. It's that simple!

Strong Structurer with Tough Qaualiy for MAXIMUM STRENGHT

Strong-structual steel construction reflects the durability of this machine. HSS tubing provides a strong and light-weight arm minimizing the driving forces required to rotate the arm.

Steel weldment of arm assembly is designed form maximum strenght while keeping the rotating weight to a minimum.

Our Most Popular Rotary Arm Stretch Wrapper - Floor Mounted Frame

This machine concept keeps the load to be wrapped stationary while the stretch film carriage rotates around the load to apply the stretch film. The rotary arm stretch wrapper is the perfect solution in situations where the load is very unstable (very tall, too heavy, too light) or in a washdown environment.

With 14 rpm stretch wrapping speed

The rotary arm stretch wrapper is the fastest stretch wrapper in his class. Up to 35-40 pallets per hr. (based on load configuration and machine options), larger, variable speed drives control all motors for maximum flexibility, heavier, and faster wrapping than most competitive machines.

FILM SAVINGS - SEPARATE 1-9 TOP AND BOTTOM WRAP PROVIDES UP TO 15% FILM SAVINGS

Separate 1-9 top and bottom wrap count provides up to 15% film savings. apply only the stretch film required at the top separately from the bottom compared to competitive models that applies a common amount to top-bottom regardless of need.

Click form more video about pallet wrapping machines

Q1:Are you factory or trading company?

A: We are factory and manufacturer. We provide great product in customize solution and service.

Q2: Where is your factory located? How can I visit your factory?

A: We are located in Shanghai, you can fly to Shanghai Hongqiao airport or Pudong airport. Wecan pick you up from the airport or your hotel.

Welcome to visit us!

Q3:How to place an order to us ?

A: Just contact us via TraderManager, E-mail, Skype, WhatsApp or telephone to confirm the product, Wire the deposit by T/T, then we will start to design and manufacture...

Q4 : What is the payment term?

A: 40% T/T deposit and 60% T/T balance payment before shipping.

For big value, we also can accept L/C.

Q5:How long is the delivery time?

A: About 20- 40 working days. The customize solution may need 60days

Q6 : What is the guarantee and service of machine ?

A: One year free warranty, life-long maintenance. We can provide free high quality service on-line, email, Tel...we also can provide door to door service, this is paid service.

Q7 : How many staff of your factory?

A: There are 100 peoples, including 12 machnical engineer, 8 electrical engineer

palletizer and wrapping machine line

Похожие товары

Гусеничный Экскаватор Liugong 35 тонн с импортным двигателем

MH-ET LIVE HB100 X 10 525 ГГц микроволновый датчик для детей возрастом от 2 до 16 лет м доплеровский радиолокатор индукционный переключатель человеческого тела

Высококачественные RL1-1442-000 для принтера, RL1-1443-000 CE651-67902 RL1-1802-000 для HP 1005 1006 1102 резины

Пылезащитное антистатическое закаленное стекло Heybingo ESD 2.5D для iphone 12 13 14 pro MAX

Shinecon 4K VR гарнитура AI08 гигантский экран 3D IMAX AR очки Pro Виртуальная реальность смарт-очки все в одном защитный чехол

Гигантские шины для карьерных грузовиков RM4A + шины 59/80R63

100% хлопок, хорошая цена, мужские брюки хорошего качества, мужские брюки, оптовая продажа, обычные брюки из полиэстера на заказ, сделано в Пакистане

Новые поступления

Новинки товаров от производителей по оптовым ценам