Гидравлическая пресс станция с двойным прессом резиновые изделия гидравлическая вулканизирующая пресс машина

- Категория: >>>

- Поставщик: Qingdao Steady Machinery Co. Ltd.

Сохранить в закладки 60565058439:

Описание и отзывы

Характеристики

Company Profile

Product Description

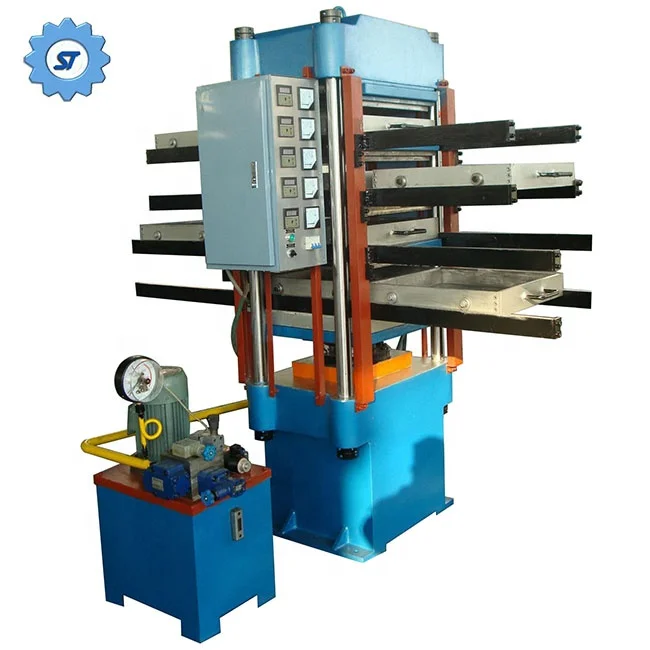

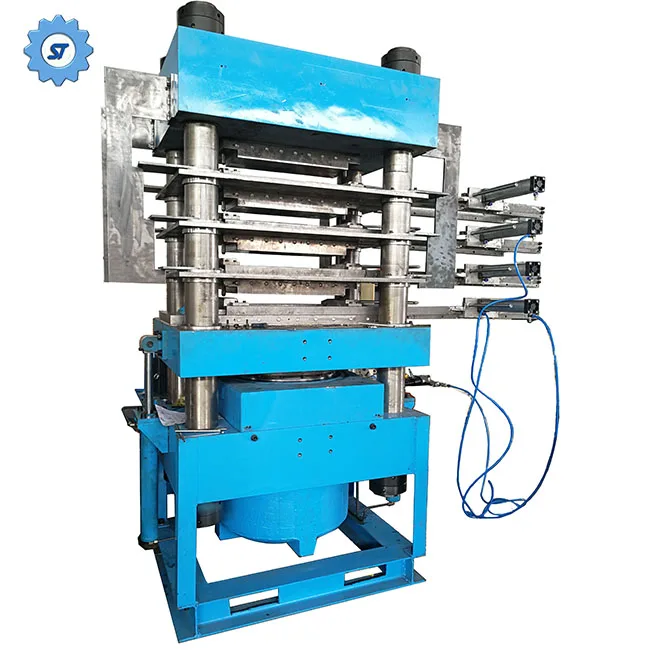

Rubber Products Plate Vulcanizing Press is rubber press machien used to make all kinds of rubber products.

The machine has different size and pressure level. And different daylight for choice according to work needs.

Machine Making Procedure

1. Design and making drawing.2. Processing machine parts strictly as per drawings, every process must have checking and control by

worker themselves.

3. QC team checking quality and precision degree.

4. Installaton the rubber hot press machine.

5. Commissioning

6. Packing while book shipping.

7. Delivery, loading container.

worker themselves.

3. QC team checking quality and precision degree.

4. Installaton the rubber hot press machine.

5. Commissioning

6. Packing while book shipping.

7. Delivery, loading container.

Rubber Making Procedure

Up mold and down mold consist a pair mold. When use the machine make the production. 1. Put rubber raw material into every cavity

of the down mold.

2. Press the mold close button on the machine.

3. The machine will close the mold, gives pressure and temperature.

4. When the set work time get out, the machine will open the mold automatically.

5. Workers get the finished rubber products out.

6. Do the next working cycle.

of the down mold.

2. Press the mold close button on the machine.

3. The machine will close the mold, gives pressure and temperature.

4. When the set work time get out, the machine will open the mold automatically.

5. Workers get the finished rubber products out.

6. Do the next working cycle.

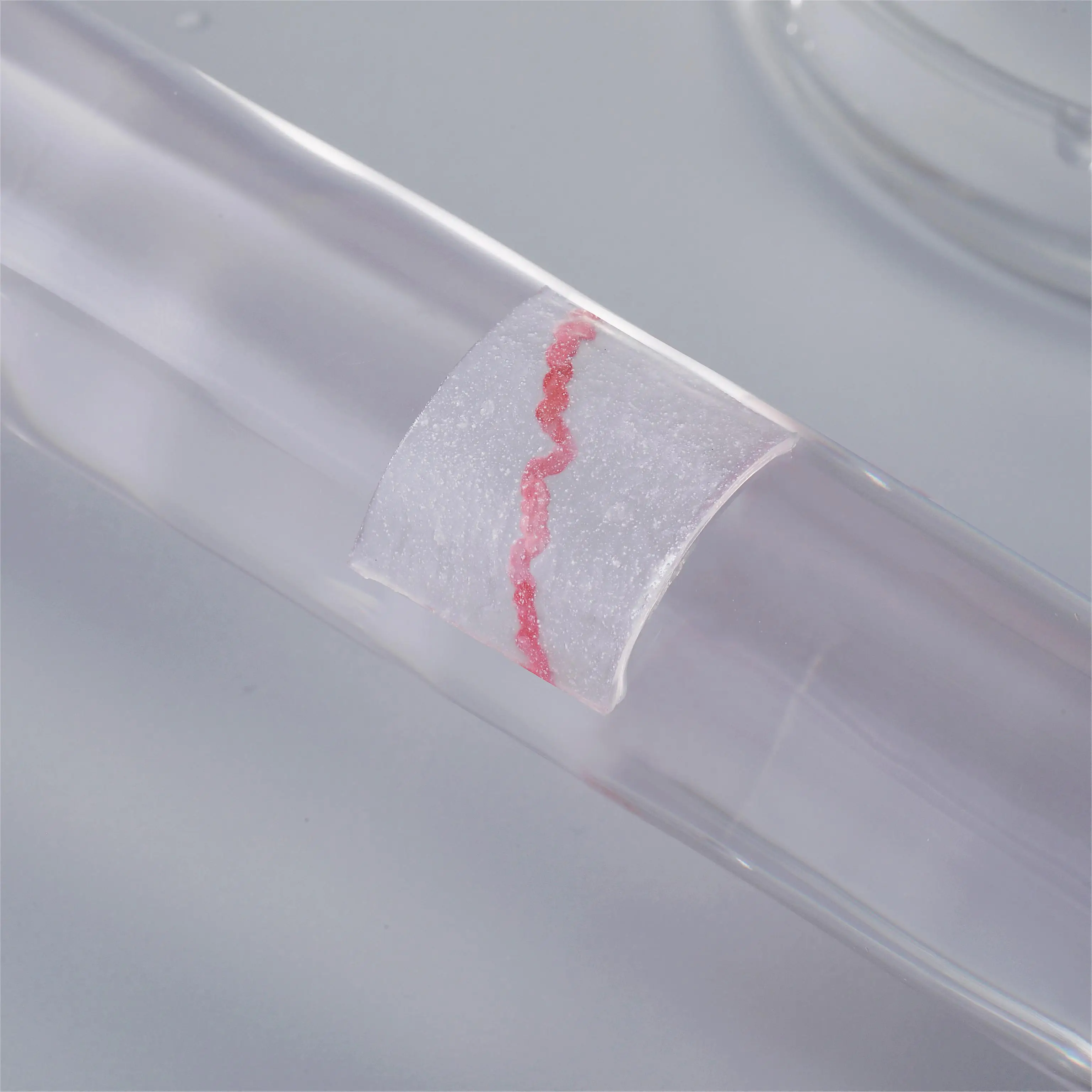

Some rubber products pictures. The rubber products shape is decided by the mold shape.

Detailed Images

We pay all effort in every detail production, from parts machining to installation and commissioing, to delivery, this ensures our machines are popular in international market.

Heating Plate Technology

Heating plate machining, drilling, grinding and heat treatment, ensures surface hardness and quality in use.

Piston

Piston adopts chilled hard cast iron, high precision machining and fine grinding treatment. Ensures the piston is super wear-resistant and durable in service life.

Valves

All valves adopted are international quality, which ensures the valves moments are accuracy, reliable, trustworthy, and long servive life.

Electronics

electronics adopts Schneider or CHNT brand. And our wire layout desing is very scientific.

So the machine electronics is very reliable even in the harsh working condition.

So the machine electronics is very reliable even in the harsh working condition.

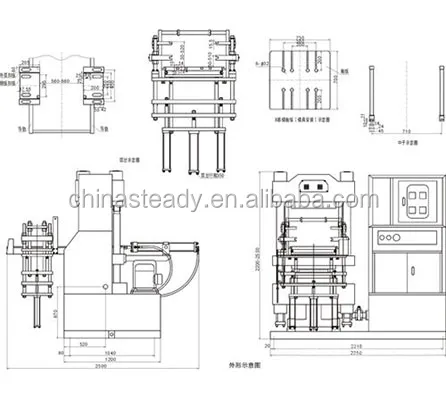

Size Information

Below is common used rubber press machine models. If you need other size or pressure, please just feel free to contact us.

Model | 350x350x2 | 400x400x2 | 500x500x2 | 600x600x2 | 750x850x2 | 600x600x2 |

Nominal Mold Clamping Force(MN) | 0.25 | 0.5 | 0.8 | 1 | 1.6 | 2 |

Heating Platen Size(mm) | 350x350 | 400x400 | 500x500 | 600x600 | 750x850 | 600x600 |

Working Layer | 2 | 2 | 2 | 2 | 2 | 2 |

Piston Diameter(mm) | ø150 | ø200 | ø250 | ø300 | ø360 | ø400 |

Piston Stroke(mm) | 250 | 250 | 250 | 250 | 500 | 300 |

Daylight/ Platen Spacing(mm) | 125 | 125 | 125 | 125 | 250 | 150 |

Unit Area Pressure(Mpa) | 2.1 | 3.1 | 3.2 | 2.78 | 2.5 | 5.6 |

Main Motor Power(KW) | 2.2 | 2.2 | 2.2 | 2.2 | 3.0 | 3.0 |

Dimension(L×W×H)mm | 1500x400x1350 | 1800x500x1600 | 1800x550x1700 | 2000x700x1700 | 2000x1000x1900 | 2550x960x2100 |

Weight(KG) | 500 | 950 | 1800 | 2300 | 3800 | 4800 |

Mold Closing Speed(mm/s) | ≥12 | ≥12 | ≥12 | ≥12 | ≥12 | ≥12 |

Mold Opening Speed(mm/s) | ≥12 | ≥12 | ≥12 | ≥12 | ≥12 | ≥12 |

Related Products

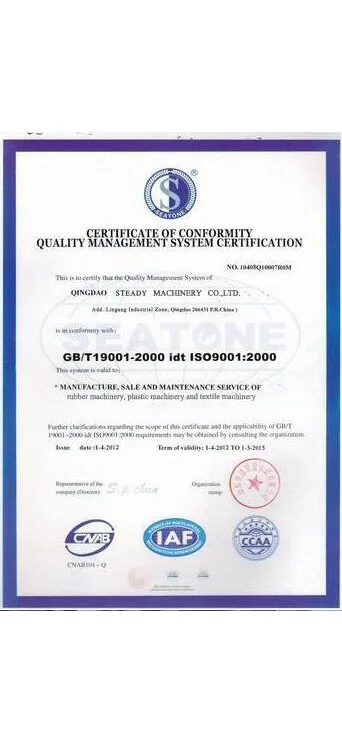

Certifications

Packing&Shipping

If the ordered quantity is not enough to a full container load, we'll use fumigation free wooden box with pallet base to ship the machine. Which is strong in long time sea transportation even with transshipment. If the rubber press machine ordered get to full container load, we'll directly use container comet to my factory to load them.

Related Goods Loading

Customer Photos

After Sales Service

Technical Support

Training customers‘ how to use the machine and how to make the production. And machine maintenance. And according to customers'

condition, we can help customers decide what configuration machine to use.

condition, we can help customers decide what configuration machine to use.

Похожие товары

PO термоклей для сборки слоев пенополиэтилена EPE, расширяемая Полиэтиленовая упаковка, Полиолефиновый клей, нетоксичный

5K 10K 15K 20K 25K 50K 100K резиновая головка для кондиционера, Медная головка, датчик температуры

0,30 $ - 0,50 $

Фабричная б/у обувь, дешевая б/у обувь в тюках

Синтетическая абсорбируемая биосовместимая Коллагеновая Мембрана для регенерации костей

Плащ с вышитыми пайетками для женщин, халат для женщин с узором в стиле Абайи, мусульманское платье, Традиционная Музыкальная одежда

Совершенно новый сертифицированный EEC электрический автомобиль Dongfeng EC35 с левым рулем, Электрический мини-грузовик

22 000,00 $

Набор токарных инструментов pt12 мм, 9 шт., хвостовик токарного станка с ЧПУ для работы по металлу, карбидная Расточная штанга

55,30 $ - 64,53 $

Новые поступления

Новинки товаров от производителей по оптовым ценам

Светлая Золотая морская солнечная энергия ландшафтное украшение постмодерн минималистский стиль чистая ручная роспись маслом 24x3 1 дюйм/60x80

35-53 $

Европейские антикварные простой Последние двойной металлической кровати

Автоматизированная складская система автоматического хранения в Гуанчжоу Eyda с эффективными стеллажами и

10 000-35 000 $

Декоративный чехол для PS5 Сменный Чехол консоли пластины Playstation5 пылезащитный с защитой от царапин

7,50-7,70 $

Лучшее качество детские подгузники для сухих подгузников новорожденных размер 2 4 и большие доставка или

3 $

Выключатель для формованного корпуса Schneider NSX100N 50KA AC 3P3D 25A TMD новая модель C10N3TM025

Буф2-.. М .. Краны

Оптовая продажа высококачественный сублимированный клубничный порошок Заводская поставка

5,50-6,40 $